DED

ESPRIT CAM, Alma CAM Partner for Robot Additive DED Programming

Collaboration to provide customers with an end-to-end solution for robot programming, simulation, verification, collision detection, code generation and more.

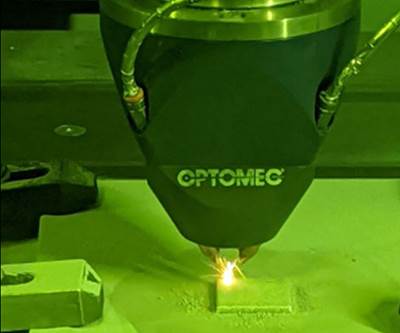

Read MoreOptomec Metal 3D Printers Designed for Research, Production

Compact Directed Energy Deposition (DED) machines include automation for batch processing.

Read MoreDP Technology Announces Support for Additive DED Manufacturing

DP Technology has released support for additive directed energy deposition (DED) manufacturing in its latest product update. ESPRIT’s additive DED cycles include additive simulation and verification, as well as global support from ESPRIT’s technical teams.

Read MoreOptomec's Aluminum 3D Printing Capability Uses Directed Energy Deposition

Aluminum DED processing is said to open the transportation and aerospace industries to AM and repair of complex aluminum alloy parts.

Read MoreLaser Mechanisms FiberWeld DH Designed for Production Applications

RAPID 2020: Laser Mechanisms’ FiberWeld DH is a high power, laser wire direct energy deposition (DED) head for processing macro-scale industrial and aerospace components and tooling.

Read MoreOptomec Releases Pure Copper DED Process

Optomec has developed a pure copper Additive Manufacturing process using Optomec’s LENS directed energy deposition (DED) systems.

Read MoreThe Hidden Complexities of Wire Arc Additive Manufacturing

Lincoln Electric Additive Solutions’ robotic metal 3D printing process is a choreographed dance between welding, robots, automation, heat management and machining. The new venture may have a distinct advantage in the field: its parent company’s 125 year-old legacy.

Read MoreVideo: What is Directed Energy Deposition?

DED is an additive manufacturing process that builds features or parts in metal by placing material where needed.

WatchRobot Is Production Solution for Laser Metal Deposition

The move from prototyping to production might involve a move from machine tool to robot, but development work between Formalloy and the robot suppliers means the process and programming do not have to change.

Read MoreWire Arc Additive Manufacturing Delivers Low Buy-To-Fly Ratios

Manufacturers in the aerospace industry buy expensive raw material with one common goal: to make it fly. To reduce its buy-to-fly ratio (the ratio of material inputs to final part output), this company turned to wire arc additive manufacturing to create near-net shape parts.

Read More

.jpg;maxWidth=400;quality=70)