Robot Is Production Solution for Laser Metal Deposition

The move from prototyping to production might involve a move from machine tool to robot, but development work between Formalloy and the robot suppliers means the process and programming do not have to change.

In metal additive manufacturing (AM), the move from prototyping to production might involve a very different machine platform, but the process does not have to change.

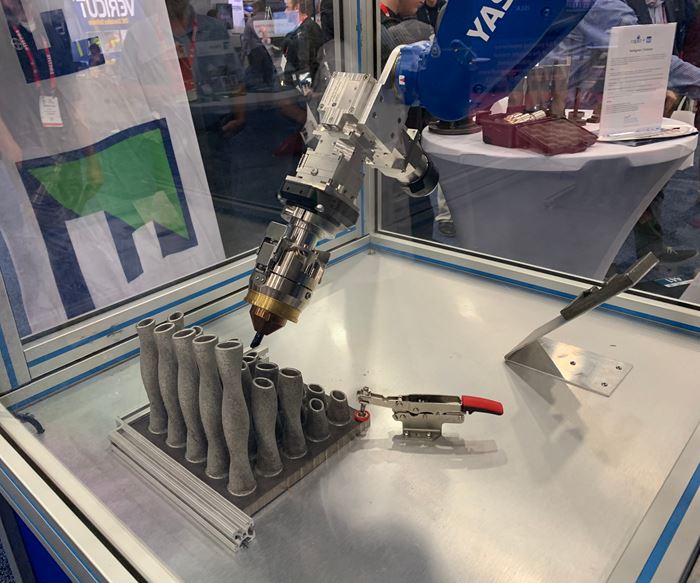

Formalloy was showing the demonstration seen in the photos above at the recent Rapid + TCT event. This demo of a robot using the company’s laser metal deposition (LMD) head ties together much of our recent coverage, including various posts on AM and robots, one in particular on metal AM with robots, and an article and video interview about Formalloy’s pursuit of the promise of LMD.

According to Formalloy cofounder Melanie Lang, a metal-deposition-based production process might be proven on a stand-alone machine tool, but in production, a robot might be the most versatile solution. The company has worked with robot supplier Yaskawa to enable a robot to run the same G-code program that might have run first on the LMD machine. As our article describes, the head is even easy to change from one to the other.

For more about this year’s Rapid + TCT, check out our video coverage and our 10 impressions of the show.

Related Content

-

Big Metal Additive: The Difference Between a Shape and a Part Is Quality

Preparing to scale directed energy deposition to ongoing full production is not a technological challenge: DED is ready. But it is an organizational challenge, says the company founder. Here is what it means to implement a quality system.

-

How 3D Printing Aids Sustainability for Semiconductor Equipment: The Cool Parts Show Bonus

Hittech worked with its customer to replace fully machined semiconductor trays with trays made via DED by Norsk Titanium. The result is dramatic savings in tool consumption and material waste.

-

3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.