Video: What is Directed Energy Deposition?

DED is an additive manufacturing process that builds features or parts in metal by placing material where needed.

Directed energy deposition (DED) is a metal additive manufacturing (AM) process in which there is no powder bed, but instead metal is precisely applied where it’s needed. I talked about DED with Tim Bell of Siemens, who was with BeAM when this video was filmed. Also seen here is Gene Granata of CGTech—hear him talk about simulation in DED in this related video.

Transcript

Peter Zelinski, Additive Manufacturing

Directed Energy Deposition (DED) is a metal additive process that delivers metal instead of working within a powder bed. I talked about this with Tim Bell of Siemens who, at the time of this conversation, was with DED machine maker BeAM.

Directed Energy Deposition is a particular type of metal additive process. Describe DED.

Tim Bell, Siemens (formerly with BeAM)

DED is simply taking blown powder or welding wire, feeding it through a nozzle and introducing a power source or energy type to melt the powder wire, create a melt bowl and then apply the melt bowl using G code and a traditional machine tool.

Peter Zelinski

So, DED is the oldest metal additive process.

Tim Bell

Historically, we called it cladding. Cladding DED is much older than powder-bed fusion, but hasn't had the fanfare that powder-bed fusion has had.

Peter Zelinski

So, let's talk about that. It is the oldest metal additive process, not necessarily an unsophisticated process, it's advanced since those cladding days you're describing. Talk about DED today, where the technology has come to today.

Tim Bell

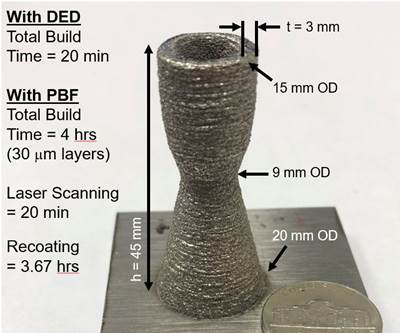

Sure, and I would say size is number one. I would say there are structural components within gas turbine engines, within the engine, that traditionally are made from large origins and they machine 80% of it and throw it away. And we're not trying to help them work on [whether or not they] can create near net shape with 10% machine left to do. So, I would say those large complex geometries and components that require extensive machining, those are the target parts that people are coming to us with.

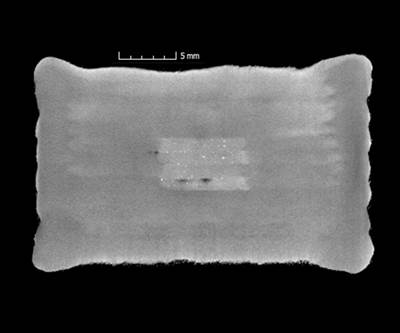

With today's technology and more powerful, more accurate lasers and our ability to more accurately project the materials into the the power source, the energy source, now we can create really refined depositions. You know, we have deposition accuracies in a plus or minus 4,000 range.

Peter Zelinski

Is there a type of part or type of application where DED is stronger compared to this other modality of metal additive?

Directed energy deposition: [a] metal additive process that probably most resembles a CNC machine tool. The deposition head is following tool paths [and] deposition paths, similar to a CNC machine. It has a control like a CNC machine tool, and it has five-axis capability. That is not typical of metal additive. We can appreciate the value of five axis in subtractive machining. Talk about the value in additive.

Tim Bell

The biggest value is you don't need support structures. We just position the BART and we always keep the build normal to the machine. Five axis also gives us the freedom to repair existing components or add features to them. Think of a duct where you would go to a factory and you would see them making flanges and bosses and tubes and they would weld it all to a piece of pipe. Well, you can just mount that piece of pipe into the machine and come in and print all of those flanges because you can access all sides of the component.

Peter Zelinski

Talk about design rules for DED. What are the kinds of design considerations that are distinctive to this process?

Tim Bell

That's a tough question. You're limited to your deposition width, right? If you want to do a single wall component, and you have a nozzle that's one millimeter or two millimeter, to build a one and a half millimeter wall, you have to do two steps or you have to do a half spacing with a specific overlap. It all comes around to designing to the deposition width. The design rules are much freer than they are for powder-bed fusion. There's not as many. Our problems are typically thermal-based because of the heat generated for their build envelope.

Peter Zelinski

Talk about how a foundation in CNC machining helps a manufacturer more quickly adopt DED.

Tim Bell

Quite simply, they know G code. They know how to come in and set g54. Understanding tool offsets and work coordinate zones and how machines are dynamic — their acceleration, their deceleration, their feed rates — it's all the same.

Related Content

What Is the Role of Directed Energy Deposition (DED)? We Are Still Discovering It

The applications go well beyond repair. Recently posted articles find many different use cases for DED, including its expanded application for production parts.

Read MoreVideo: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

Read MoreHow 3D Printing Aids Sustainability for Semiconductor Equipment: The Cool Parts Show Bonus

Hittech worked with its customer to replace fully machined semiconductor trays with trays made via DED by Norsk Titanium. The result is dramatic savings in tool consumption and material waste.

Read More7 Lessons From General Atomics on AM for Aircraft Part Production

A manufacturing leader overseeing the way additive manufacturing is transforming unmanned aerial systems (UASs) offers observations about succeeding with 3D printing as an aircraft production process.

Read MoreRead Next

Video: How Simulation Assists Directed Energy Deposition

Scrapping an AM part is potentially as costly as scrapping a machined part. Directed energy deposition is an additive process that can benefit from a resource that safeguards machining: simulation software.

Read MoreThree Cool Uses for Directed Energy Deposition

Most machining professionals don’t like to admit that they ever make mistakes, but every now and then wouldn’t it be nice to have an “eraser” to go back and repair a gouge or fix a nicked edge? Or maybe you took off a bit too much material on that last machining pass and you’d like to add it back? Well, directed energy deposition (DED) enables you to do that and more.

Read MoreWhat Is Directed Energy Deposition?

Analyzing directed energy deposition and powder-bed fusion provides a thorough understanding of the extra machining necessary for a “near-net shape” versus a “net shape” manufacturing process.

Read More