Laser Mechanisms FiberWeld DH Designed for Production Applications

RAPID 2020: Laser Mechanisms’ FiberWeld DH is a high power, laser wire direct energy deposition (DED) head for processing macro-scale industrial and aerospace components and tooling.

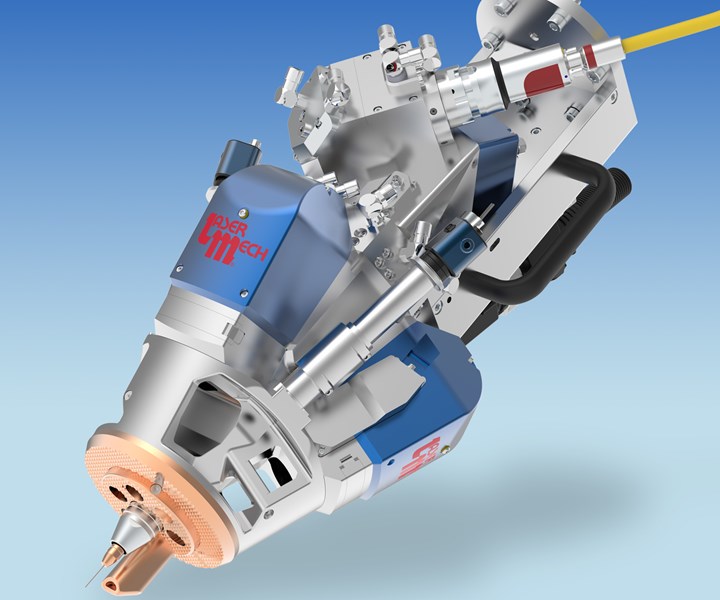

Laser wire direct energy deposition head.

Laser Mechanisms’ FiberWeld DH is a high power, laser wire direct energy deposition (DED) head for processing macro-scale industrial and aerospace components and tooling.

Engineered for high duty cycle production applications, FiberWeld DH features direct-cooled reflective optics, back reflection protection and wire feed. The head’s advanced optical design permits filler wire to be fed directly into the beam path – right into the center of the melt pool. This allows the deposition process to have total directional independence. In addition, FiberWeld DH’s easily accessible, protective cover glass extends the life of internal optics.

Related Content

-

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

-

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

-

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.