Optomec's Aluminum 3D Printing Capability Uses Directed Energy Deposition

Aluminum DED processing is said to open the transportation and aerospace industries to AM and repair of complex aluminum alloy parts.

Share

Read Next

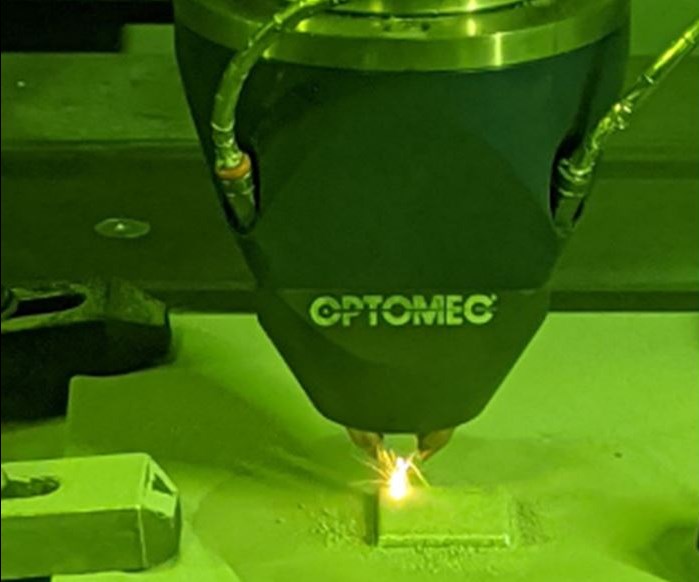

Optomec LENS DED system printing aluminum powder onto an aluminum substrate.

Optomec has announced an advancement in capability for the company’s LENS Directed Energy Deposition (DED) systems relative to AM and repair of aluminum alloys. This innovation can be used to deposit any aluminum alloy, including those recently developed specifically for improved properties with AM processing, the company says.

This development for the Optomec DED process opens the transportation and aerospace industries to AM and repair of complex aluminum alloy parts using powder-based DED. Additionally, the use of Optomec’s LENS simultaneous five-axis system enables the processing of aluminum alloy parts with complex geometries without the need for support structures. Deposition of aluminum alloys in a controlled atmosphere glove-box with very low levels of oxygen and moisture ensures achievement of components with superior mechanical properties.

David Otazu, LENS Applications Engineer states, “Our engineers have developed process parameters for aluminum alloys to provide an excellent surface finish, high deposition rates and a density of ~99.9%.” With this advancement, Optomec LENS systems can successfully process all common materials used for AM including Steels, Titanium, Nickel, Copper, and now, Aluminum.

Related Content

-

Faster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

-

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

-

A Tour of The Stratasys Direct Manufacturing Facility

The company's Belton manufacturing site in Texas is growing to support its various 3D printing applications for mass production in industries such as automotive and aerospace.