Composites

Metal Parts Are Now Within Reach for Users of Polymer 3D Printers

An option for accessible metal 3D printing: New metal composite filament from BASF Forward AM has made it easy for Austrian company Sparox 3D to pivot its Ultimaker FFF capacity into metals, without major additional investments in skills or equipment.

Read More3D Printing Reduces Time, Cost of Building Molds for Composites

Massivit 3D’s cast-in-motion technology uses a 3D printed gel to expedite production and lower costs associated with making molds for large, fiber-reinforced composite parts.

Watch3D Printed Composite Bracket Versus Machined Steel: The Cool Parts Show #41

Can a 3D printed composite bracket work as well as one machined from steel? Can it also be faster to make and cheaper to produce? In this episode of The Cool Parts Show we explore a new way of manufacturing a bracket for a helicopter door hinge, and similar small parts today made from metal.

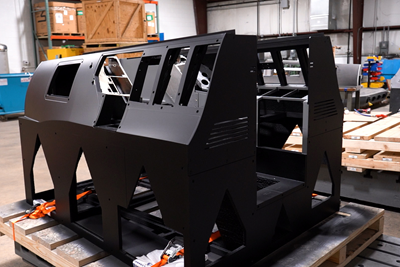

WatchVideo: Functional Excavator Features 3D Printed Parts

Oak Ridge National Lab's Project AME swapped an excavator's cab, stick and heat exchanger for 3D printed parts. Stephanie Hendrixson and Peter Zelinski get the scoop.

WatchAirtech’s Dahltram Resins Qualified for Use on All CEAD AM Flexbot Platforms

The AM Flexbot is one of CEAD’s AM solutions, using Comau robots directly controlled by Siemens Sinumerik. It offers an option to combine 3D printing and milling into one automated process.

Read MoreUsing Large-Format Additive Manufacturing for Serial Production

First tools, then production parts. This pattern with industrial 3D printing at small and mid sizes has now come to the biggest additive machines as well.

Read MoreReshoring, Tooling, Sustainability and More: Top 10 Stories of 2021: AM Radio Episode #9B

Reviewing our most-viewed stories of the year revealed some of the topics that have been top-of-mind for additive manufacturers. Read or listen to the countdown.

Listen3D Printed Magnets: The Cool Parts Show #38

Is it possible to 3D print a magnet? In this episode of The Cool Parts Show, we learn how magnets have been printed successfully at Oak Ridge National Lab, and the implications this has for energy, material conservation and supply chains.

WatchSetforge Begins Hybrid Series Production of Composites

Hybrid composite manufacturing has enabled Setforge to expand into new markets with cost-competitive parts that handle higher specific loads than steel.

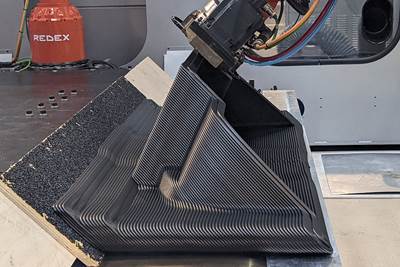

Read MoreThermwood Adds Angle Layer Printing to Large Scale Additive Manufacturing Systems

This third print orientation for its LSAM systems enables users the ability to print at a 45-degree angle.

Read More