There are many small metal parts in use today that don’t necessarily need to be metal — but for decades, machining these components from a metal blank has been the fastest, most cost-effective way to make them. 9T Labs has developed a composite manufacturing process utilizing 3D printing that aims to challenge this. By applying thermoplastic and continuous carbon fiber to reinforce the material only where needed, the company can create parts that are much lighter and even cheaper than a metal alternative, while still being strong enough to do the job. In this episode of The Cool Parts Show, we pit a composite bracket for a helicopter hinge against its machined steel counterpart. | This episode of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- 9T Labs

- More on the Red Series technology and applications for this solution

- Other examples of 3D printed brackets

- Another lift test with a composite 3D printed hook

- Wagner Machine in Norton, Ohio, site of the lift test

Transcript

Stephanie Hendrixson

Can a 3D printed thermoplastic composite compete with machined steel? Find out in this episode of The Cool Parts Show.

Stephanie Hendrixson

This episode of The Cool Parts Show is brought to you by Carpenter Additive. The company's PowderLife solution is a combination of hardware and software technologies designed to help AM users manage their metal powders. Stay tuned after the episode for more on how the system works.

Pete Zelinski

I'm Pete

Stephanie Hendrixson

I'm Stephanie.

Pete Zelinski

Welcome to The Cool Parts Show.

Stephanie Hendrixson

This is our show all about cool, unique, interesting, unusual 3D printed parts.

Pete Zelinski

I'm gonna go out on a limb and say that these are our cool parts. They look like brackets.

Stephanie Hendrixson

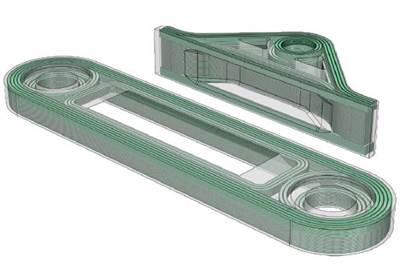

They are brackets. So all of these brackets are for a helicopter hinge assembly. We have the original metal machined version here and the 3D printed version here. So these were created to be a lighter weight, more cost effective alternative to the machined steel version. And they do that through a combination of continuous carbon fiber and thermoplastic. These are composite brackets.

Pete Zelinski

I guess simple observation. First, you said lightweight, lightweighting. It's extreme in this case, the metal one is so much heavier. It's like I don't even trust this it's so light. How can this be a helicopter part? How can this do a serious helicopter function? How can this do the same thing that this does? It's so much lighter.

Stephanie Hendrixson

So they do perform equivalently and we will get to that. But the key with this one is that it does that while being lighter weight which results in fuel savings, and it's also cheaper to manufacture.

Pete Zelinski

Okay manufacture, so I look at the metal one, and I can see that it was machined. The light catches the feedlines I can see the milled surface here. That reminds me that I ought to be able to look at this 3D printed one and see the layer lines and I don't. I'm not sure I would know this was 3D printed. How was it made?

Stephanie Hendrixson

So this was 3D printed, using sort of a weird and unusual 3D printing process, which you know, is something I love to talk about on this show. So these brackets were produced by 9T Labs, which is a Swiss company that has come up with a way of making small composite parts like this, using 3D printing. So let me introduce you to Yannick Willemin. He is the director of marketing and business development for 9T labs. And he can elaborate on this a little bit more.

Yannick Willemin

We do layer by layer, so pretty traditional 2d printing. And afterward, we have the consolidated form, but it's not fully consolidated as we would expect in composites. And we ended up doing post-consolidation. This is comparable to compression molding. So we developed our own press here for different reasons to be even more accurate in the consolidation coming to temperature and pressures. And at the end, we really reached parts with porosities below 1%, which means they are performing on the high level for a longer time and are fully consolidated. You don't see the layer anymore as we would traditionally see with 3D printed parts.

Stephanie Hendrixson

So they have a 3D printer that basically has two extruders on it, there's one that is extruding thermoplastic like something like PEEK or PEK usually, and then the other is laying down a continuous carbon fiber to reinforce it. But when it comes off the printer, it's a little bit too porous. It's not fully dense yet. And so then they go through a compression molding step to solidify everything, eliminate that porosity and make the parts fully dense. So this bracket was actually printed in a couple of different pieces and then assembled, they added the metal inserts here, and then compression molded to bring it all together.

Pete Zelinski

Whoa, whoa, whoa, whoa. So you need a mold for this?

Stephanie Hendrixson

Yes, you do.

Pete Zelinski

So we talk about 3D printing. And one of the big advantages is getting away from tooling. There are a lot of freedoms that come from a toolingless part making process. Is it still 3D printing? Is it still beneficial the way 3D printing is if you have to use a tool?

Stephanie Hendrixson

So yes, it is if you're coming at it from this sort of like composites mindset. So if you think of something, a composite part like say, like a boat haul or something, you start with a mold and then you have to lay your reinforcing fiber, like your carbon fiber tape or whatever, down into that mold, infiltrate it with some kind of resin, like the glue that holds everything together and then cure it all. And for the composites industry, the tooling is not necessarily the bottleneck or the hang up. It's placing all of those fibers and things exactly where you want them. And so the benefit that 9T Labs is bringing with this 3D printing solution is automate the material placement. They're not bothered by the fact that they still need a mold because being able to use a 3D printer for that automation allows you to get to a place where you can make smaller components, things that can fit in the palm of your hand, using composites much more cost effectively.

Pete Zelinski

That's kind of a subtle point. But let's talk that out, I think you're winning me over here. One of the changes that 3D printing is advancing is polymer replacing metal. Polymer finding applications in a larger range of uses and specifically, reinforced polymer. Say for example, carbon fiber reinforced polymer. And so think of the episode we did about the big flight simulator housing that was made of polymer composite, or the underwater automated vehicle, the robot sub. So we've done episodes on polymer used in what would be metal applications like that. But those were big parts. And the fiber reinforcement in those cases was random, the fibers landed in random directions, because the feed material was pallet. And so you're describing a case where the role 3D printing plays is not so much the outer form, but it's concerned with getting that fiber exactly where you want it to be.

Stephanie Hendrixson

Yeah, and so those other applications that you mentioned, where you're dealing with the chop to carbon fiber, inside of the plastic, what happens is, then you get that reinforcement distributed evenly throughout your part, which you may or may not want. It might be that you only need reinforcement around some critical areas. And so part of 9T Labs' solution, there's actually software involved, they have a tool that will help you optimize the placement of the carbon fibers. And then within the printer, those heads don't have to move together. The fiber doesn't have to go everywhere that the plastic does. And so as a result, in a part like this, you're only placing the reinforcement exactly where you need it, which is then saving that material, you're not using all that carbon fiber if you don't need it, which can even result in more weight savings. I think Yannick has more to say about that.

Yannick Willemin

In the textile technique, I would say the traditional way to do it, if you need 60% fiber volume content at one highly loaded point of the part, then you will have a very homogeneous 60% fiber volume content distribution all over the part, which is kind of over engineering. So you will probably use more materials than you really need in the part and we wanted to challenge that. So what you can do, you can really place maximum fiber volume content where you need it and remove it when you don't need it. On one side, it's nice on the pure engineering side to just put the material necessary to sustain the loads. But it has also an impact on costs. So of course, the cost of those parts is driven by the amount of fibers in it, because the polymer itself is way cheaper. So if you can balance it out to sustain the loads, while having less fibers, you will also have an economic advantage here.

Pete Zelinski

I guess what I see is, this is a simple component, this is a pretty simple piece of hardware, yet, we're learning about a pretty sophisticated 3D printing processI Is this simple hardware, a good use case for that sophisticated process?

Stephanie Hendrixson

So I think it is because we've talked about the lightweighting already, but just to kind of illustrate that further, this original machined steel bracket weighs about 125 grams. This 3D printed version, the composite version weighs about 25 grams. So that's a pretty significant weight savings, especially when you think about the fact that there are four of these on each helicopter. The other advantage here is cost. This costs about half as much as this one does to make.

Pete Zelinski

Alright, this is 25 grams, this is 125 grams. So this literally weighs just 1/5 as much. And I guess the promise I see in that is how many metal parts are there in the world that look kinda like this? Metal hardware holds together, structures, systems machines. And what I'm hearing you describe is because of this is relatively cheap to produce and it's strong, there is the opportunity that brackets and other hardware elements, connective elements that we take for granted as metal parts today, they could be polymer, they could be reinforced polymer, and our machines get lighter and a whole lot of hardware in the world could feel this way.

Stephanie Hendrixson

Absolutely. I think Yannick has more to say about that

Yannick Willemin

For now there is quite some interest. Of course it's kind of a niche market in a certain way. But there's different markets in different industries, where they are such parts. Either metal parts, which can be now challenged with composites because also the economics are correct here for the parts. It's also interesting challenging for some other applications, existing composite processes because they are not material efficient and we often speak about the circular economy and recyclability, and so on. So first criteria is just to avoid wasting in the first place before thinking about recycling. So those are certainly key points, which are interesting to tackle with 3D printing.

Stephanie Hendrixson

So machined metal can be challenged by composites when the composites can compete on speed and cost. So 9T Labs knows that this isn't going to be solution for every metal part out there, but they see a sweet spot. Things that are made in quantities between maybe 100 and 10,000 parts per year, this could be a pretty compelling solution for.

Pete Zelinski

I guess I come back to my first question. Are these two parts really comparable is one as strong as the other one.

Stephanie Hendrixson

So I know it's difficult to wrap your mind around. So I actually arranged for a test of these brackets. So the 3D printed version is actually optimized to hold 500 pounds a little less than 500 pounds, which is the weight of the helicopter door, and then some. And so here are both of these brackets together, lifting some steel beam, which weighs over 900 pounds. So you can see they are sharing the load equally. I've actually since learned from Yannick that they've further optimized the 3D printed version of this bracket. And now the new version can hold 900 pounds all by itself.

Pete Zelinski

That is a really impressive test you came up with.

Stephanie Hendrixson

I had a lot of help.

Pete Zelinski

Alright, I think I got this. This bracket touches on multiple themes I hear us talking about from time to time. Brackets is one of them. 3D printing loves brackets. Brackets are a great use case for what additive manufacturing is able to do. In addition to that, plastics replacing metal in a growing range of applications because of 3D printing, specifically reinforced polymer, carbon fiber reinforced. In this case, 3D printing is not so much concerned with the outer form, it's concerned instead with getting the fiber reinforcement placed exactly where you want it. And that fiber placement, it is based on a design simulation that uses software from 9T labs and 9T Labs also develop the 3D printing process that creates a part like this. The outer form is realized through compression molding, and so there is a tool that's used in this. So that makes this kind of a counter intuitive 3D printing application relative to how we usually think about 3D printing. This is not toolingless, it uses a tool to achieve the final form and also make it stronger through compression. And this is also not a part that's free of assembly, this was assembled from multiple components. In spite of that, it was still cheaper and faster to manufacture compared with the machined metal part, and it performs just as well. It holds just as much load, it meets the same requirement that this metal part does And it is 1/5 the mass.

Stephanie Hendrixson

Yeah, I think you got it. So that's it for this episode of The Cool Parts Show. Pete, thank you for entertaining this weird and strange 3D printed part that happens to involve tooling.

Pete Zelinski

You're welcome. Thank you for bringing this to us. If you have a cool part of your own you want to tell us about maybe it would be an episode of the show, email us CoolParts@AdditiveManufacturing.media.

Stephanie Hendrixson

I also want to give a special thank you to Mike Wagner and the entire team at Wagner Machine for the use of their overhead crane and to my dad, Greg Monsanty for building our test rig. If you liked the show, we hope you'll leave us a like leave us a comment and make sure to subscribe so you don't miss any episodes. Thanks for watching.

Stephanie Hendrixson

Thanks again to our sponsor Carpenter Additive. In addition to supplying metal powders, the company also offers services, software and hardware to help AM users manage their powder. One example is the PowderLife system, a combination of cloud based tracking software with hardware designed to make powder handling easier. Two key components are the PowderLife hopper and the Automated Docking Station. Luke Boyer, manager of PowderLife applications and Andrew Holliday Applications Engineer explained how the system works.

Luke Boyer

So today when a user of additive manufacturing is receiving powder, they oftentimes receive it in either 5, 10, 15 maybe a 20 kilo bottle, but they're receiving pallets of them and you're receiving 10, 20, 50, hundreds of these bottles. The user has to look and segregate and store them appropriately so the bottles don't get mixed up and it requires a lot of lifting and moving and labor.

Andrew Holliday

The components of PowderLife are all based around making powder management systems on the additive manufacturing shop floor easier to use for the operator, cleaner, as well as more traceable. Three of those basic parts of Powder Life are our PowderLife hoppers or our storage containers for powder. The second would be Automated Docking System that allows materials to be pushed in and out of machines with no human contact. The third would be our PowerLife online software system that allows you to trace this powder as it goes through your shop floor.

Luke Boyer

The hardware and software together just helps really streamline that and improve the final users experience and let them concentrate on going from design to the part itself. It takes the headache of powder management out of the equation for them.

Related Content

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read More3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

Read MoreTwo 12-Laser AM Machines at Collins Aerospace: Here Is How They Are Being Used

With this additive manufacturing capacity, one room of the Collins Iowa facility performs the work previously requiring a supply chain. Production yield will nearly double, and lead times will be more than 80% shorter.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreRead Next

Video: 3D Printing with Carbon Fiber

Make parts as strong as metal on a desktop machine, the company says.

Read MoreVideo: 3D-Printed Composite Hooks Lifts Hundreds of Pounds

AM challenges expectations about which applications and part types call for metal and which are appropriate for polymer.

Read MoreFiber-Reinforced 3D Printing Expands Control, Applications for Composites

9T Labs’ deposition process places continuous carbon fiber only where necessary to save material, reduce waste, and more precisely control the structure of preform composites.

Read More

.jpg;width=70;height=70;mode=crop)