A progression that manufacturers often follow with additive manufacturing goes like this: A company starts out using 3D printing to make tooling. Then, whether it expected to or not, that same manufacturer finds opportunities to apply the additive capability to making production parts.

The story has played out again and again for companies using small to midsize AM equipment, but now we see an example of the same development happening for some of the biggest AM machines.

Additive Engineering Solutions (AES) of Akron, Ohio, was founded to make large-scale tooling using its Big Area Additive Manufacturing (BAAM) machines from Cincinnati Incorporated — and we first met the company when we reported on this niche the company was staking out. More recently, however, AES also has been using the large-format 3D printing capability to make large-format production parts.

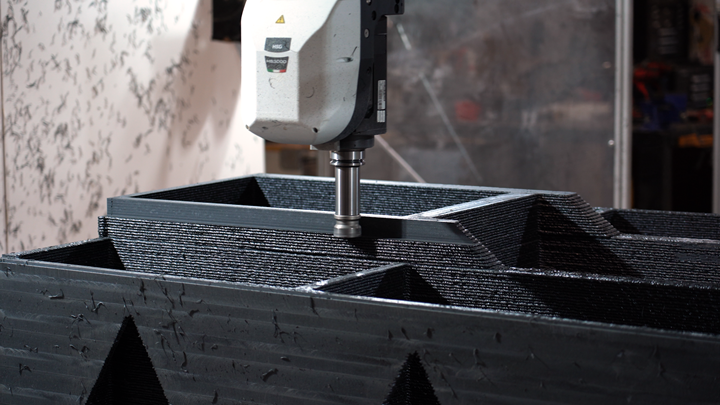

AES produced a series of flight simulator housings like this one for L3Harris. The defense engineering company adds the electronics and outer coverings, but it no longer faces the assembly work and long lead time to obtain this structure.

The part above is an example. It is the housing for a flight simulator developed by L3Harris. This aerospace and defense engineering company turned to AES because it saw the chance to dramatically simplify manufacturing using AM.

The near-complete flight simulator cockpit seen above was made from carbon-fiber-reinforced polymer, and it offers an extreme case of assembly consolidation. The housing consists of just three large 3D printed components, replacing what previously would have been an assembly of thousands of smaller pieces.

AES’s cofounders are Andrew Bader and Austin Schmidt. Big Area Additive Manufacturing machines are in the background. AES is an example of an AM company (like this one and this one) that we have known and reported on since its inception.

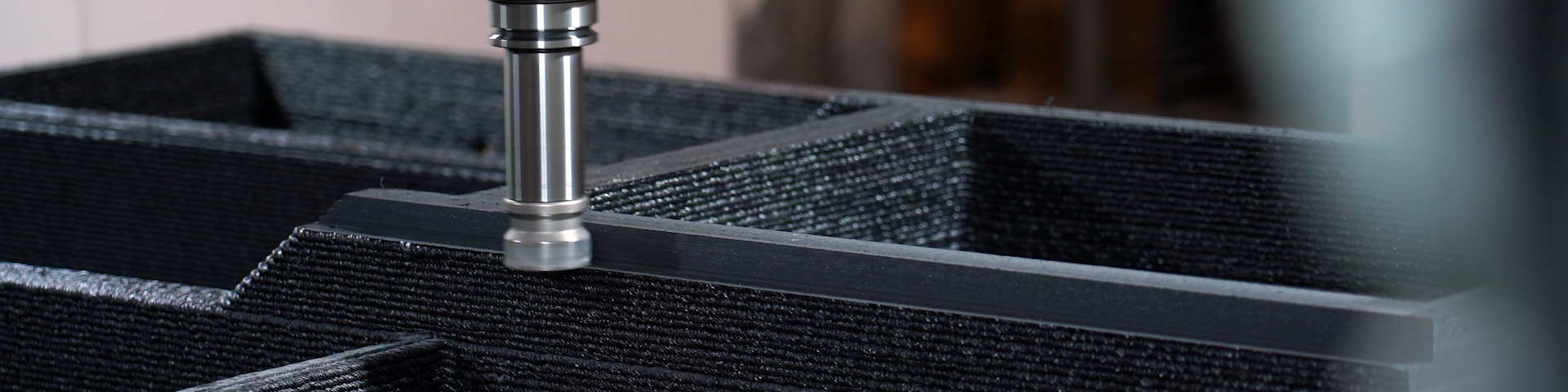

The housing parts were designed not only for 3D printing, but also for machining. Leaving sufficient machining stock allowances was part of this.

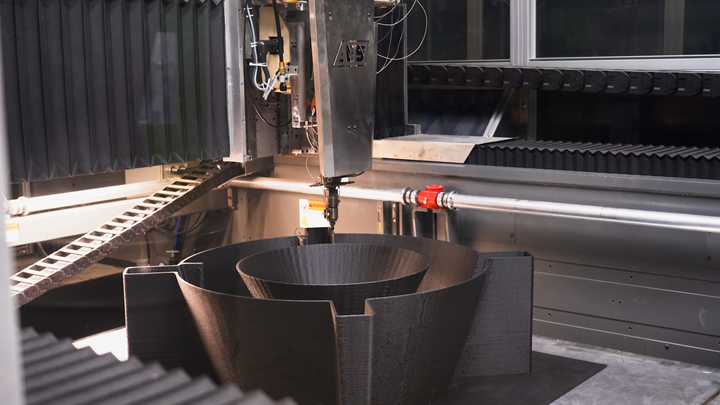

A production part for a different customer made using large-format AM: hull sections for an autonomous underwater vehicle. We have featured both applications on The Cool Parts Show: Watch our episodes about the flight simulator and about the robot sub.

Related Content

-

What Does AM Want? Here Are 4 Aims (Maybe 5) That Additive Manufacturing Is Driving Toward

Certain freedoms and contributing factors allow additive manufacturing to realize its full promise for production.

-

Two 12-Laser AM Machines at Collins Aerospace: Here Is How They Are Being Used

With this additive manufacturing capacity, one room of the Collins Iowa facility performs the work previously requiring a supply chain. Production yield will nearly double, and lead times will be more than 80% shorter.

-

Additive Manufacturing Versus Cavitation

The design freedom possible with laser powder bed fusion (LPBF) metal 3D printing is making it faster and easier to produce complex anticavitation devices for valves.