For a manufacturer to adopt powder-based metal 3D printing takes significant commitment. In addition to the cost of the 3D printer itself, that business also needs to be prepared to foot the bill for postprocessing equipment, safety infrastructure, personal protective equipment, powder handling and more — if not add personnel to run the new printer as well. The payoff can be great, but getting to the point of efficiently operating this equipment can be a challenge. It’s no wonder that many companies needing metal 3D printed parts often opt to outsource this work for as long as possible.

That was the case for Sparox 3D, an innovation project spun out of Wien Energy GmbH in Austria that provides spare parts for the energy sector and other industries. The business supplies metal and polymer replacement parts made via 3D printing, but until recently, only the polymer parts were produced in-house; metal parts manufacturing was outsourced because of the hurdles involved in implementing powder bed fusion (PBF) or another kind of direct metal 3D printing. Eventually, though, it seemed necessary to insource this capability. In exploring all the various technologies and machines available, the team was surprised to learn about an option that would allow Sparox to produce its own metal components without a major capital investment. In fact, they could continue to utilize the desktop polymer printers they already owned.

With a small hardware upgrade and new material in hand, Sparox has pivoted from exclusively producing polymer parts on its Ultimaker 3D printers to producing green metal parts. Working with BASF Forward AM’s materials and the latter’s service provider Elnik GmbH for debinding and sintering of the green prints, Sparox can now obtain dense metal parts quickly and affordably while maintaining better control over their design. End-use items made this way are already in use within Wien Energy as well as external customers.

3D Printing Spare Parts for the Energy Sector and More

Sparox 3D is a business-to-business platform that since 2018 has been manufacturing spare parts and custom products for Wien Energy and parent company Wiener Stadtwerk, as well as external clients. The organization primarily serves customers in the energy sector, as well as transportation and oil and gas — all industries operating many legacy systems with a critical need to keep those systems up and running for as long as possible. When parts break, it is important to replace them quickly and desirable to optimize them against future failure if possible.

“The production of the required spare part by means of 3D printing is often cheaper than the purchase of a completely new system.”

Since 2018, Philipp Pink has served as the company’s technical director of 3D printing and helped to deliver on this dual mission by working with customers to recreate or rebuild their components in plastic or metal. “We have been able to implement additive manufacturing in all divisions of our parent company, such as public transport, energy suppliers, electricity and gas network operators, IT, and even home care,” Pink says. “The production of the required spare part by means of 3D printing is often cheaper than the purchase of a completely new system.”

Pink was also part of the company’s investigation into standalone metal additive manufacturing (AM) capacity. “We were looking for metal 3D printing, but the costs of DMLS [direct metal laser sintering] and DED [directed energy deposition] were very high,” Pink says. Aside from the price of a metal 3D printer itself, the company also needed to take into account auxiliary equipment for postprocessing, material handling and safety, all of which represented added expense.

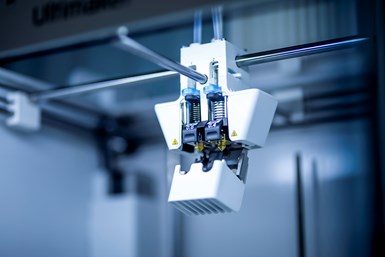

With all this to consider, adding metal 3D printing capacity still seemed impractical — that is, until “We discovered that we could do this with our Ultimaker printers and keep manufacturing in-house,” Pink says. Sparox already had access to the Wiener Stadtwerke fleet of about 14 polymer fused filament fabrication (FFF) 3D printers from Ultimaker that it used to make tools and replacement parts in plastic; thanks to collaboration with BASF Forward AM, these printers are now compatible with a metal-filled filament that can be applied to build green metal parts.

Metal Parts From FFF

BASF Forward AM’s Ultrafuse 17-4 PH combines stainless steel powder with thermoplastic binders to support printability via fused filament fabrication (FFF).

Photo Credit: Forward AM

The method that Sparox uses today to produce metal parts looks similar to how it 3D prints polymer parts, with a few differences. Parts are built up slightly oversized on the Ultimaker printers using Ultrafuse 17-4 PH filament, a BASF Forward AM filament that contains both metal powder and thermoplastic. In-house postprocessing is as simple as pulling the parts off the build plate and possibly removing supports — in other words, no more complex than for a neat thermoplastic print. The green part is then shipped to Elnik for debinding and sintering to remove the nonmetallic content and bring it to its final density. The technique allows Sparox to maintain control over the critical design and initial build phases of metal part production, while outsourcing debinding and sintering to process experts.

There are several distinct factors that contribute to the success of the metal fused filament fabrication (MFFF) technique:

Material

First is the material — BASF Ultrafuse 17-4 PH prints like a more conventional thermoplastic filament but carries a substantial amount of stainless steel powder plus additives that keep the matrix flowable while stabilizing the metal particles. The binding agents are removed in different phases of the postprocessing. “We use a two-binder system,” explains Tobias Rödlmeier, business development manager for the metal ecosystem at BASF Forward AM. “We have the primary binder, polyoxymethylene, and the second binder, a polyolefin which is basically inert to the catalytic environment of the debinding process.”

This means that debinding removes only the primary binder, leaving behind the stainless steel and the polyolefin that serves “as a backbone, holding the 3D shape together,” Rödlmeier says. The debound part is in what is known as a “brown state,” and must go on to the sintering step to remove the polyolefin and achieve its fully dense final state.

Software Tools

Because debinding and sintering remove material from the green print, parts must be designed to compensate for this material loss in addition to being optimized for 3D printing and end performance. Fortunately, the shrinkage is repeatable and predictable; the green parts typically shrink by about 16% in the X and Y axes, and about 20% in Z. Functionality incorporated into the Ultimaker 3D printer software helps designers achieve final metal parts in the correct dimensions.

“Working closely with BASF we can take out some of those question marks for the end user and really make it a streamlined process,” says Miguel Calvo, Ultimaker’s chief technology officer and senior vice president, printers and peripherals.

Sparox also relies on design guidelines to create MFFF parts that will survive debinding and sintering, as well as rough simulations of the sintering process.

3D Printer Hardware

Ultimaker’s wear-resistant print core CC has a hardened steel nozzle and titanium heat break to extend durability. Photo Credit: Ultimaker

Those familiar with neat polymer FFF can quickly learn to print MFFF parts on their existing equipment, but filled metal filaments like Ultrafuse are abrasive and can be tough on printers.

"The new CC print core Ultimaker developed to handle these materials proved to be advantageous for metal printing,” Calvo says. “In particular, the 0.4-mm nozzle produces excellent green state print quality."

The Ultimaker print core CC is available in two different nozzle diameters. The 0.6-mm nozzle (illustrated by the sample part in the background) is suitable for thermoplastics reinforced with carbon fibers and other materials, while the 0.4-mm nozzle (foreground) provides the fine detail and accuracy needed for metal FFF applications. Photo Credit: Ultimaker

Postprocessing, Off-Site

Once printed, green parts are shipped out for catalytic debinding and sintering in a furnace under hydrogen atmosphere. This two-step process is the same as that used in metal injection molding (MIM) and results in stainless steel MFFF parts with high strength and hardness.

BASF Forward AM has sintering partners in the United States and in Europe that handle debinding and sintering as well as heat treat, should the components require it. The equipment is booked on a biweekly, fixed schedule which simplifies planning and ensures parts never spend more than 2 weeks out for postprocessing.

Relying on specialists to manage these steps frees MFFF users from the startup costs and other hurdles that would need to be overcome to handle debinding and sintering in-house. “That knowledge you need to gain, and that equipment you need to buy — that’s just too much if you want to use an FFF printer and you want to do metal now,” Rödlmeier says. “So let a professional expert do it.”

“The barrier to adopt the technology is extremely low.”

Without the need to invest in debinding and sintering equipment, 3D printing users can access metal 3D printed parts more easily and cheaply. There’s no need to slice a metal part from a build plate or for special PPE to handle powdered metal. Changing from one material to another is as simple as swapping the spool of filament. “You don’t need a specialist to run the machine or all the extra pre- and postprocessing equipment,” Calvo says. “The barrier to adopt the technology is extremely low.”

Spare Parts at Sparox 3D

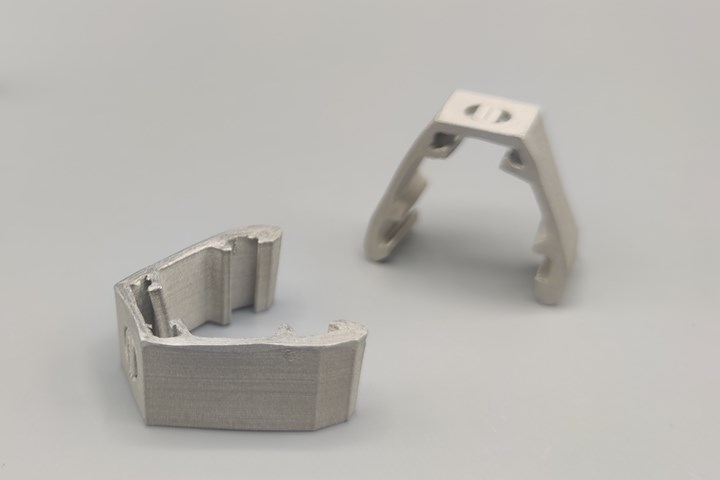

Sparox 3D has already found success with the MFFF strategy. The technique has been used for parts ranging from gate locks to customized tool inserts. In one case, the organization used MFFF to create clamps needed to secure special photovoltaic (PV) solar panels. Certain panels could no longer be fastened because the guide rail mounting was outdated, and the clamp needed had been discontinued. Making replacement clamps via MFFF provided the weather-resistant performance this component needed, and also allowed for a material upgrade to stainless steel from the original aluminum.

Sparox produced these solar panel clips using the MFFF workflow, avoiding the need to replace the mounting guiderails and taking advantage of the opportunity to upgrade the material from aluminum to stainless steel. Photo Credit: Sparox.eu

“We managed to optimize the component to make it even more durable, and thus prevent a conversion from the old mountings at a cost of several thousand euros,” Pink says.

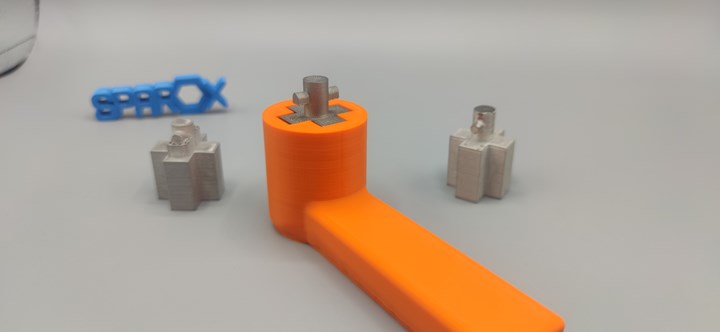

Another use case came from Wien Energy’s own facility management. In the company’s high-rise building, windows undergo regular maintenance that involves replacing the seals and cleaning the sealing area, which requires the use of a special tool to open the window.

“Since the windows are certainly older than I am, all special tools for opening are broken or lost,” Pink says. “Thanks to MFFF technology, we were able to remanufacture the tool, optimize it and successfully integrate it into the maintenance work. Now the windows can be serviced regularly again and do not have to be replaced.” What might the solution have been without MFFF? “Buy new windows,” he says, underscoring the expense saved by this tool replacement.

This small tool insert 3D printed by Sparox allows Wien Energy staff to open the windows in the company’s building for cleaning and maintenance. Without it, the company might have needed to replace all the windows in the high-rise. Photo Credit: Sparox.eu

The MFFF strategy has worked well for Sparox 3D in part because the organization has been able to pivot existing knowledge of polymer extrusion into metals, without needing to take on or become experts in the additional process steps this pivot entails. Working with partners on the debinding and sintering keeps metal part production affordable for Sparox without introducing too much lead time. In particular, the company values the level of control it can maintain over the design and manufacture of its parts while keeping the process fast and affordable.

“The know-how for designing and manufacturing remains in your own company,” Pink says.

Related Content

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreRead Next

Metal 3D Printing in the CNC Machining Job Shop

For metalworking businesses looking for a metal 3D printing option free of the concerns of handling metal powder, metal fused filament fabrication provides additive capabilities with easy implementation and material flexibility.

Read MoreHow Investing in Metal AM Is Different

GE Capital helps manufacturers finance additive manufacturing equipment, but the investment goes beyond the 3D printer. Production AM demands a production infrastructure, and requires a long-term strategic approach.

Read MoreSolving MRO Challenges with Bound Metal Deposition

Three case studies reveal how Desktop Metal’s second-generation Studio System bound metal deposition printer eliminates common safety hazards of metal AM, enhancing the technique’s value for maintenance, repair and operations (MRO) applications.

Read More

.jpg;width=70;height=70;mode=crop)