Composites

HAMR Joining Neighborhood 91 Additive Manufacturing Production Campus

HAMR will join Neighborhood 91’s existing additive manufacturing ecosystem which includes tenants Wabtec, Arencibia, Cumberland Additive and Metal Powder Works.

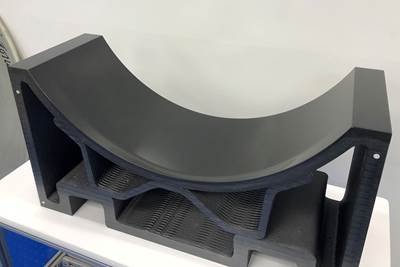

Read MoreAirtech Validates High-Temperature Polymer for Large-Format Tooling, Moldmaking

According to the company, the polymer is well suited for high-temperature applications such as hot forming tools, autoclave molds, oven molds and self-heated molds.

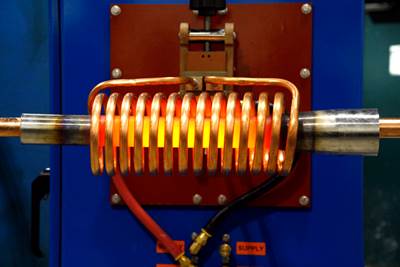

Read More3D Printing Supports Induction Coils — and Emergency Needs

As a participant in Michigan’s Project DIAMOnD initiative, Tucker Induction Systems received a 3D printer to use any way it saw fit, provided the capacity remains available in case of emergency. Use cases and lessons learned as part of this distributed manufacturing network.

Read More3D Printing Increases Efficiency Of Wind Turbine Blade Alignment

A Markforged digital repository and 3D printers enable faster, more accurate and less costly manufacture of a variety of tools and blade components across Vestas sites.

Read MoreComposites-Ready 3D Printers Produce High-Strength Parts

IMTS 2022: Stratasys’ new printers are said to offer high stiffness and strength materials in a hardened machine ready for composite material printing.

Read MoreFuse 1+ 30W SLS 3D Printer for Faster Printing, High-Performance Materials

The printer integrates upgraded components — including a more powerful laser — to enable new high-performance materials and deliver superior throughput so customers can produce parts up to two times faster.

Read MoreRoboze Pro Series 3D Printers for Faster Production

The Pro series is designed to enable flexible and cost-effective processes that make industrial production stronger, faster and less expensive.

Read MoreHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MorePostProcess Develops Resin Removal System for Composites, Ceramics

The company says the PLM-405-SUB chemistry formulation removes both excess resin and ceramic filler residue from 3D printed parts simultaneously in one detergent.

Read MoreMassivit 10,000 Additive Tooling System for Composites Manufacturing

Rapid + TCT 2022: The system utilizes the the company’s Cast In Motion technology, which is said to enable direct printing of complex molds using high-performance casting materials.

Read More