Composites

Thermwood LSAM 510 Additive Printer Useful for Molding, Tooling

RAPID 2022: Thermwood’s LSAM 510 additive printer features a single fixed gantry and a 5 × 10 ft. moving table with a 4 ft. maximum print height and a maximum temperature of 450°C.

Read MoreAdditive for Composites and Composites for Additive: AM Radio #17

CompositesWorld’s Jeff Sloan joins Peter Zelinski in an episode of the AM Radio podcast about how composites and 3D printing are changing one another.

ListenHow Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

WatchSiemens, Roboze Working to Create Complete Additive Manufacturing Workflows

Siemens chooses Roboze ARGO 500 industrial 3D printer for its Charlotte Advanced Technology Collaboration Hub (CATCH) to further industrialize additive manufacturing in the U.S.

Read MoreMarkforged Acquires Teton Simulation

Integration of Teton’s cloud native simulation software into Markforged’s Digital Forge platform will enable manufacturers to validate advanced composite parts for demanding production applications.

Read MoreAerospace Applications for 3D Printed Composites: AM Radio #15A

3D printed composites are taking the place of traditional metal parts in a specific niche of the aerospace industry.

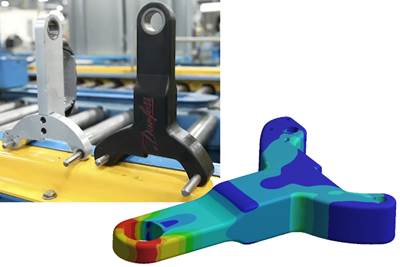

ListenCan Metal Parts Be Replaced With 3D Printed Composites?

High performance materials such as carbon PEEK have allowed Werco Manufacturing to 3D print parts for aircraft trainers that function like metal. But can this extend to end-use aircraft parts?

Read MoreCustom Canine Wheelchair From Carbon Fiber-Reinforced PP: The Cool Parts Show #44

A dog with a condition that affects her mobility gets a custom 3D printed wheelchair in this episode of The Cool Parts Show, enabled in part by a new polypropylene filament.

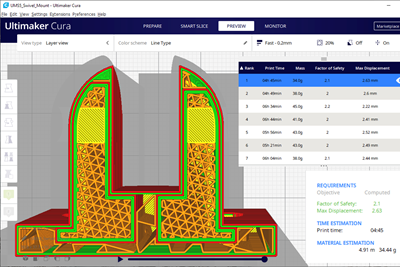

WatchWorkflow Validates 3D-Printed Composite Part Performance

A new workflow connecting 3D printing data with finite element analysis (FEA) enables simulations of fiber-reinforced 3D-printed parts that can predict mechanical and structural performance.

Read MoreRoboze’s Helios PEEK 2005 Polymer Replaces Metal in Industrial 3D Printing

The company says the super polymer for 3D printing is well suited for applications that require specifications of lightness, mechanical strength and heat resistance.

Read More