Additive Manufacturing Is Succeeding in Production! Here Are Examples

We are no longer predicting that additive manufacturing will be used in production — because it already is. Find real stories of 3D printing for full production at AM's leading edge in this collection.

Read MoreVideo: Can 3D Printed Parts Hold Self-Tapping Screws?

Automotive light maker Varroc Lighting Systems will soon begin using additive manufacturing for plastic production parts fastened into assemblies. Here are the results of its tests with self-tapping screws.

WatchJabil Prepares for Production AM: It’s Down to the Basics Now

Jabil is getting ready for additive manufacturing to take its place as a production option in addition to conventional processes such as molding and machining. AM can and will fill this role, the company says — the focus now is on controlling cost and assuring quality and reliability.

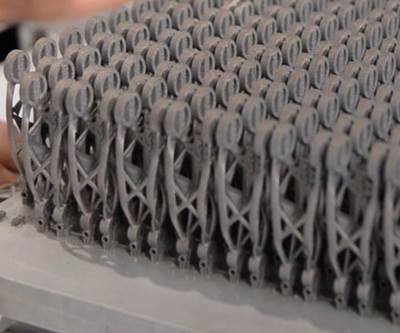

Read MoreVideo: Controlled Porosity Can Be Functional Advantage Realized via 3D Printing

A wall of metal that looks solid is actually 90% dense, allowing gas to pass through. Mold venting is one application.

WatchVideo: The STL File Can Produce Surface Defects in 3D-Printed Parts

Timothy Simpson of Penn State University discusses the influence of model definition in additive manufacturing and what to do about its effects.

WatchVideo: Support Structures Are Misnamed! How to Understand Anchors in Additive Manufacturing

Supports or anchors can account for a significant share of both the engineering investment and material use in metal additive manufacturing. Michael Hansen of SLM Solutions discusses the role and importance of support structures.

WatchVideo: Metal AM Affects Plastics Production via Conformal Cooling

Additive manufacturing allows cooling channels within mold tooling inserts to follow the form of the tool rather than being straight drilled holes. Here’s why this matters.

WatchVideo: The Impact of Part Orientation on Cost and Build Time in AM

A different build orientation might mean fewer layers and less support structure, though the part might need to be redesigned to take advantage of this different orientation.

WatchWhy Robots and Additive Manufacturing Go Together

3D printing and robots enable one another. We miss the possibilities of one if we do not consider the other. The combination includes AM for end effectors, robots for 3D printing parts, and different modes of metal and plastic production.

Read MoreVideo: How Simulation Assists Directed Energy Deposition

Scrapping an AM part is potentially as costly as scrapping a machined part. Directed energy deposition is an additive process that can benefit from a resource that safeguards machining: simulation software.

WatchVideo: What is Directed Energy Deposition?

DED is an additive manufacturing process that builds features or parts in metal by placing material where needed.

WatchRobot Is Production Solution for Laser Metal Deposition

The move from prototyping to production might involve a move from machine tool to robot, but development work between Formalloy and the robot suppliers means the process and programming do not have to change.

Read More