For Additive Manufacturing, Software Is as Important as the 3D Printer

AM is the process that both requires and realizes the possibilities of manufacturing software. Recently posted articles cover software tools for additive — each article with a companion video.

WatchGenerative Design Improves Micromobility FUV: The Cool Parts Show #19

Arcimoto’s lightweight “Fun Utility Vehicle” gets even lighter thanks to parts that could only come from additive manufacturing. On this episode of The Cool Parts Show, some of the craziest automotive parts you have seen.

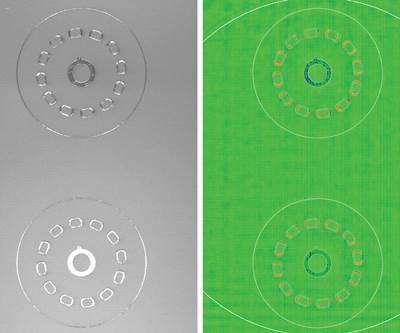

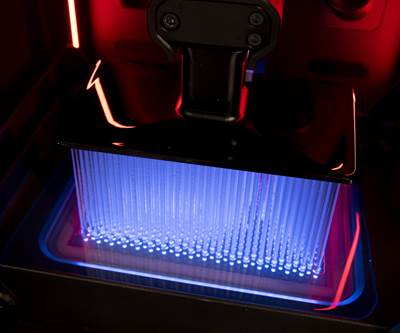

WatchBy Mapping Layer Height, Velo3D Shows Where Part Is Distorting (Includes Video)

Height measurement reveals what layers and what part features are potential problem areas in the metal additive manufacturing build. Watch the video to see how software provides insights from layer height data.

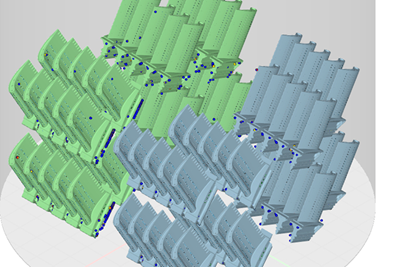

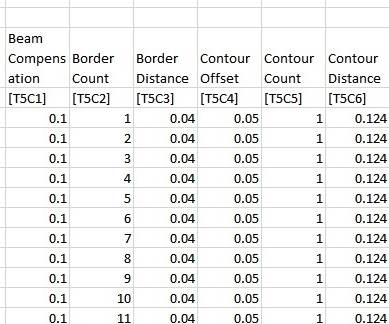

WatchYour Metal AM Process Development Tool? A Spreadsheet (Includes Video)

Spreadsheet integration with Renishaw software allows for fast programming of metal additive manufacturing test builds. Watch video for demonstration of defining many laser parameter combinations for use in a single test.

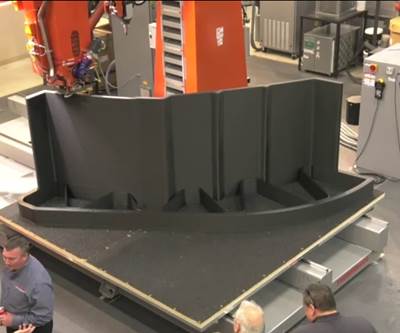

WatchCGTech Extends Simulation to Thermwood LSAM (Includes Video)

Large-scale additive manufacturing platform is the largest 3D printer yet simulated. Watch video for example of how simulation using program G-code catches an error that would otherwise lead to a failed build.

Watch3D Printed Tool for CNC Machining: The Cool Parts Show #17

Guhring uses additive manufacturing to make an end mill with optimized internal channels. We visit a machine shop to test the tool on this episode of The Cool Parts Show.

WatchAdditive Manufacturing and Sustainability Go Together — Here Is Why

3D printing enables sustainable production through recycled materials, end-of-product-life-cycle solutions, and helping to realize eco-friendly products.

Read MoreGenerative Design to Bring Weight and Cost Savings for Micromobility FUV

The “Fun Utility Vehicle” from Arcimoto is already in production, and already lightweight. But after just 30 days of redesign for additive manufacturing, the company discovered major components could be made lighter still, and production could be made simpler.

Read MoreAM’s 2020 Advance: How the Crisis Created Conditions for Additive Manufacturing to Leap Ahead

Stories we’ve found within the pandemic period reveal 3D printing’s promise for scalable, flexible production and rapid product development.

WatchHow PrinterPrezz Aims to Realize a Manufacturing Model Tailored to Medical Devices

3D printing for orthopedic implants enables innovation and better patient outcomes, but a new type of manufacturer may be needed to realize this promise. A startup focused on implant development, approval and production via additive manufacturing includes surgeons among its founders.

Read MoreLeader of New Jersey PPE 3D Printing Effort Tells Volunteers, “Stop Completely”

“PPE Made in the USA” delivers 5,000 3D printed face shields produced and distributed by 50 volunteers. As emergency passes, a high school STEM teacher’s response to the COVID-19 crisis reaches its conclusion.

Read MoreDrone Engine Replaces 13 Parts With 1: The Cool Parts Show #14

Cobra Aero discovered an opportunity for redesign it might never have found without the COVID-19 interruption providing time for product development via 3D printing. The Cool Parts Show explores how additive manufacturing is advancing during the coronavirus crisis.

Watch