Printing Solid, Simple Metal Parts in Minutes, Spee3D Process Is Competition for Casting

Kinetic energy additive process bonds metal not through melting, but with the use of compressed shop air.

When I met Byron Kennedy last year at the Formnext show, he glanced around the exhibit hall floor and admitted, “We are not competing with 99 percent of the people here.” Other metal additive manufacturing technologies such as powder-bed fusion make medical implants or aircraft fuel nozzles. His metal 3D printing technology makes brackets and other seemingly simple metal parts—but his process makes these parts quickly and cheaply.

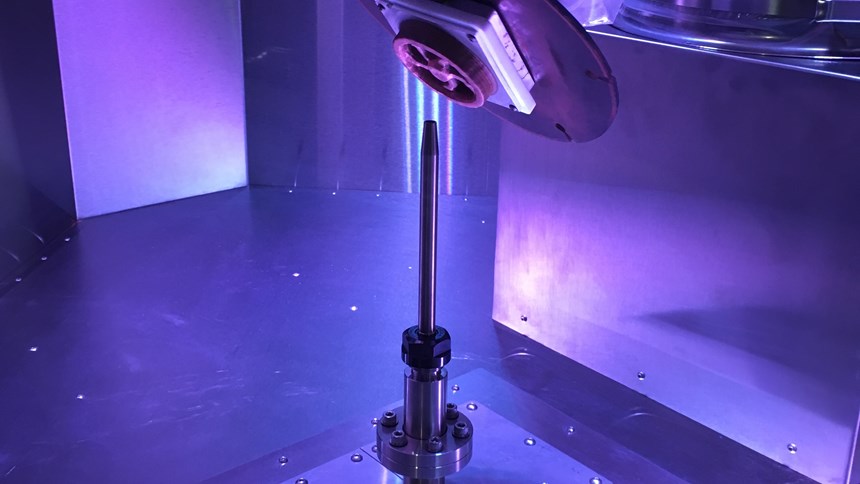

Kennedy is the co-founder and CEO of Spee3D, an Australian company that has developed “supersonic 3D deposition” into a process that additively builds metal parts. No heat is involved—that is, no melting—but instead metal powder is sprayed onto the build platform at speeds high enough that kinetic energy drives the metal bond. There is no laser on Spee3D’s machine, but rather the process is powered by a standard shop air compressor.

The company’s technology is based on a mechanism long used by the U.S. military for manual repair, with the metal spray directed by hand. Figuring out how to translate CAD files into programmed movement for the seven-axis robot manipulating a flat build surface around the stationary nozzle was perhaps the biggest challenge of developing this machine. But accomplishing this resulted in a method of building metal 3D parts that is fast relative to other AM processes—100 to 1,000 times the deposition rate of powder-bed machines, Kennedy says.

The resulting parts look and function much like castings. He sees casting, not other metal AM systems, as his chief competition. With the ability to produce solid forms six or eight inches in their longest dimension within a build time of 10 or 15 minutes, he says that “in the time it takes you to ask for a quote on a casting, we can print one.”

Related Content

-

EOS Works With Phillips Federal, Austal USA to Develop CopperAlloy CuNi30 for US Navy Submarine Industrial Base

Using the copper-nickel alloy in combination with EOS’ platforms offers new design and production capabilities for U.S. Navy submarines, while also enabling the agency to limit global supply chain disruption because parts can be produced regionally, locally and on-demand.

-

Southern Indiana’s Thriving AM Part Producer — What I Saw at Innovative 3D Manufacturing: AM Radio #49

Recorded just after the visit to the laser powder bed fusion contract manufacturer, here is a conversation exploring observations and impressions of this company and its metal 3D printing work.

-

New Equipment, Additive Manufacturing for Casting Replacement and AM's Next Phase at IMTS 2024: AM Radio #54

Additive manufacturing’s presence at IMTS – The International Manufacturing Technology Show revealed trends in technology as well as how 3D printing is being applied today and where it will be tomorrow. Peter Zelinski and I share observations from the show on this episode of AM Radio.