Europe Seeks to Develop the Jack-Of-All-Trades of Additive Manufacturing

Supported by the European Union's Horizon 2020 Research and Innovation Program, the Kraken project team aims to develop an AM machine that can process large functional components ranging to 20 meters in length, made of plastics, metal or both.

What if you had a machine that can manufacture metal, plastics and hybrid workpieces up to 20 meters in length, using both additive and subtractive manufacturing technologies? The 15 partners of the European Kraken project, which was launched in October 2016 under the direction of José Antonio Dieste, head of the mechatronics department at the Aitiip Centro Tecnológico in Spain, think such a machine would be great, productive, efficient and space-saving. Supported by the European Union's Horizon 2020 Research and Innovation Program, the project team aims to develop a machine that can process large functional components, made of plastics, metal or both. Target markets are the aerospace, automotive, energy, rail and construction industries, according to Dieste.

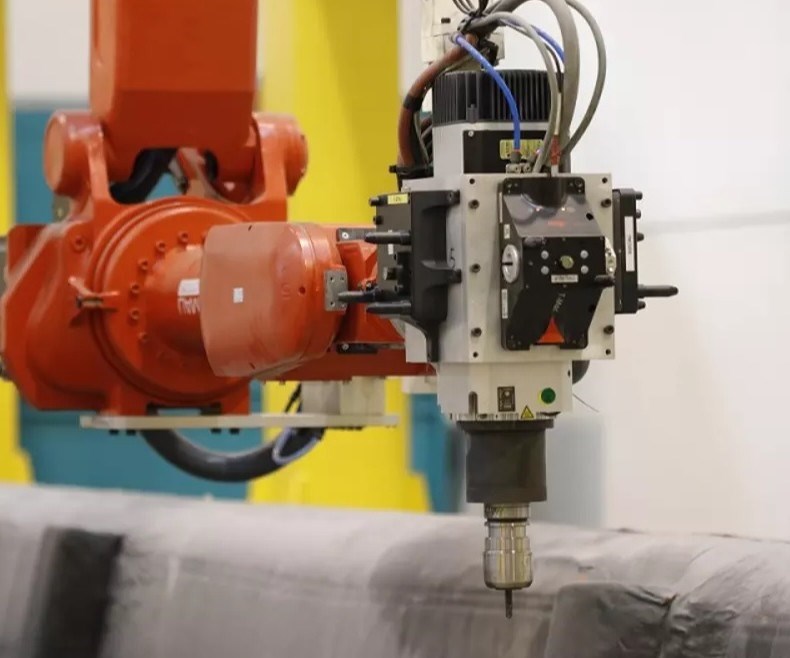

"We want to realize the dream of producing large-volume, metal, polymer-based or hybrid components additively on one machine," said Dieste at the International AM Conference, which took place in Hanover in October 2017. Combining subtractive and additive machining allows layer-by-layer AM processes, alternating fast and rough material deposition with final milling steps. Despite its potential, the development and industrial application of hybrid machines is slow, especially for large parts, Dieste said.

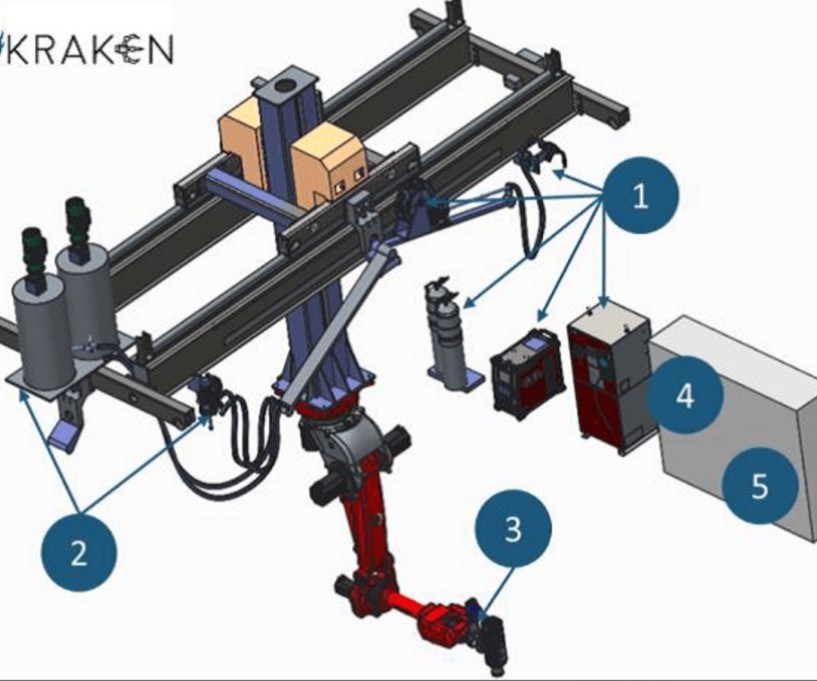

The Kraken project aims at the development of a novel, fully automated, all-in-one platform for large-volume hybrid manufacturing. The workspace is said to be up to 20 meters (67 feet) in length and accuracy is supposed to high (tolerances of less than 0.3 mm and surface roughness less than Ra 0.1 micron).

The gantry machine will enable multi-material 3D printing of aluminum grades and polymer-based materials such as thermoset Epoxy and PUR resins. For the polymer-based materials deposition rates are supposed to reach 180 kg/hr. while aluminum deposition rates are to reach 10 kg/hr. In addition to these high deposition rates enabled by arc-wire technology, the Kraken team is investigating how to integrate other metal additive technologies such as laser-wire and laser-powder-based systems.

Moreover, the machine is supposed to generate metal-polymer hybrid parts; polymer on metal or metal on polymer.

"The project will require the development of new polymer-based materials, new tools and high-speed milling concepts for optimized machining performance, as well as new sensors and controls for processing the two very different materials on one machine,” Dieste explained. "We also need new CAM algorithms for this kind of hybrid manufacturing. This includes strategies for planar horizontal layer strategies as well as new approaches to creating three-dimensional freeform surfaces. The machine will also feature in-line measurement and quality assurance systems.”

The aim of the project is, among other things, to identify business models for the commercial use of the Kraken machine as well as for the all developed in the area of software, monitoring, automation and milling as well as multi-material additive manufacturing.

Once the project progresses further, we will publish an update.

Related Content

-

Airless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

-

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

-

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.