With Binder Jet Aluminum, Ford Prepares for Production 3D Printing at Automotive Scale

Component for popular car will be the first case of continuing applications of additive manufacturing to automotive-quantity metal part production.

The production component made through binder jetting of aluminum 6061 will be part of “a very popular model” of Ford automobile. Seen here is the Ford F150 pickup, but the Ford representative did not name this or any model. Photo courtesy Ford.

For Ford Motor Co., a new automotive component design enabled by additive manufacturing (AM) will lead to a full-scale production application of metal 3D printing within two to three years, says company AM technical leader Harold Sears. Further, this achievement will be the beginning of a broader change. The development work that has gone into realizing this success will be applied to other parts. The company’s manufacturing leaders are now “confident that additive manufacturing is scalable to volumes that support automotive,” says Sears.

Ford’s previous success in 3D printing for production has involved lower volumes — quantities low for automotive, for vehicles aimed at narrow markets. Sears says the thinking now aims well beyond this. The part under development will see full-scale production for use in “a very popular model” of Ford automobile.

The part will be manufactured through binder jet. Sears did not disclose identifying details of the production component, but the work has come to light because of the success of a fundamental starting point for this application: the development of a production-repeatable process for binder jetting and sintering of a challenging metal for 3D printing, aluminum 6061. This development was the result of cooperation among engineers and material scientists at Ford and binder jet technology provider ExOne. Unlocking aluminum enables the coming production part, which Sears says fulfills much of the list of reasons to adopt AM. The shift from conventional to additive in the case of this one component will deliver weight reduction, space savings, improved part performance, and cost and time savings through assembly simplification.

“We found an application where design for additive manufacturing is just a perfect fit,” he says.

Why binder jet? It was not the first 3D printing option considered. An aluminum alloy was needed; laser powder bed fusion (LPBF) can print aluminum. Ford started there.

The laser process “gave us a nice part, but support structures [and the need to remove these structures through a subsequent step] presented a real challenge,” he says. Speed was low. Binder jet, which is frequently a higher-production-rate metal AM process compared to other metal 3D printing options, was practically also a perfect fit, Sears says — except for the glaring fact that no aluminum option yet existed for the process.

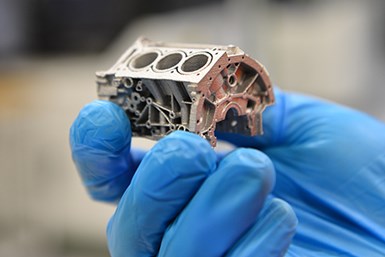

Binder jetting with aluminum was previously not possible, but Ford and ExOne have pioneered a process for binder jetting aluminum 6061, the material in the sample part here. Photo courtesy ExOne.

ExOne had aluminum development in its material roadmap. The company agreed with Ford to redraw the roadmap to accelerate development of this material. The work stretched across about a year and a half, says Sears, and was the full-time occupation of a team of people within Ford during this time. The development focused well beyond just the 3D printing, because binder jetting success entails postprocessing steps as well. Curing and sintering are key to the ultimate properties of the part. The payoff now is an industry milestone: the first process for production 3D printing via binder jet in an aluminum alloy.

Both companies see long-term significance in getting to this point, even while the first production part to benefit from the work is still under development.

ExOne CEO John Hartner says, “Developing a fast, affordable, easy way to 3D print aluminum with traditional material properties is a critical step toward lightweighting more products and delivering a more sustainable future.”

Ford’s Sears says, “High-speed aluminum 3D printing paves the way for other opportunities that we’re just now starting to take a look at because of the ability to do complex parts with aluminum that previously weren’t possible. It’s really opening doors for other opportunities.”

The extent of those opportunities is clear to the automaker’s leadership, he adds. In a recent encounter with a company executive, Sears says this leader noted he was done talking about the coming additive part, already heading to production. “He said he wanted to talk about the next additive application,” Sears says. That is, “how do we build on this foundation?”

Related Content

What Holds AM Back in Automotive Production? GM Additive Lead Describes Advances Needed

“If AM were cheaper, we would be doing more of it,” says GM’s Paul Wolcott. Various important factors relate to cost. However, the driving factor affecting cost is speed.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreA Tour of The Stratasys Direct Manufacturing Facility

The company's Belton manufacturing site in Texas is growing to support its various 3D printing applications for mass production in industries such as automotive and aerospace.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreRead Next

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read More3D Printing for Production at Ford: The Cool Parts Show #7

The parking brake bracket on the Mustang Shelby GT500 is now 3D printed instead of stamped. Learn how Ford is thinking about additive manufacturing in this episode of The Cool Parts Show.

Read MoreSpeed Is Relative in AM: A Data-Driven Comparison of Multi-Laser Powder Bed Fusion and Binder Jet Processing

There is a difference between the effective print speed and the actual cost to produce the component with AM. John Barnes compares binder jet processing with powder bed fusion for metal parts.

Read More