Articles

The Power of AM Is in Product and Process

Additive manufacturing will advance where DFAM improves product performance and is supported by the process chain.

Read MoreHigh-Speed Milling Meets Powder-Bed Additive Manufacturing

A hybrid machining center from Sodick integrates high-speed machining with direct metal laser sintering (DMLS).

Read MoreWebinar: Additive Manufacturing Needs Machining—How Should They Work Together?

Register for the free webinar by the Consortium for Advanced Hybrid Manufacturing—Integrating Technologies (CAM-IT) to be held November 30 at 2:00 p.m. EST.

Read More7 Helpful Numbers Quantify Design Rules for Additive Manufacturing

How tiny can features get? How high can walls extend? What is the longest unsupported distance a bridge of material can span between two features? These and other DMLS and SLS design rules addressed by expert from Proto Labs.

Read MoreWhat Is the Most Widely Used 3D-Printed Material?

ExOne’s CTO recently offered an educated guess. His answer highlights an underappreciated success of AM.

Read MoreEight-Axis Robotic System Prints Composite Parts

This concept machine leverages robotics to 3D print in eight axes.

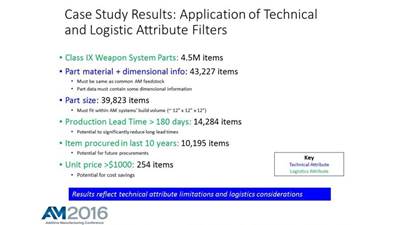

Read MoreDoD Utility Identifies Military Legacy Parts That Make the Most Sense for AM

How can the military find the best candidates for additive manufacturing out of millions of service components? It can’t without human attention, but a sorting utility helps to reduce the number to a manageable size.

Read MoreMolder’s Experience Illustrates How AM Will Interact with Other Advances

Additive manufacturing is not moving forward in isolation. It will leverage and work in harmony with other manufacturing technologies that are also moving forward.

Read MoreSuccessful Prints Require Feedback Before They Go to the Machine

DFAM is unlike designing for subtractive machining or injection molding, and requires acute understanding of the machine, process and materials involved.

Read MoreCaterpillar Leader Urges, Embrace AM for the Right Reasons

FOMO—fear of missing out—is not the right reason. Valid reasons to 3D print relate to cost or time saving and delivering value.

Read MoreProgress Toward a Model for DMLS

Research funded by America Makes is creating a model that will minimize thermal distortion in DMLS.

Read MoreHighlights from AM2016

At this year’s gathering in Chicago, presenters shared their insights and experience on the industrial application of additive manufacturing technology.

Read More