DoD Utility Identifies Military Legacy Parts That Make the Most Sense for AM

How can the military find the best candidates for additive manufacturing out of millions of service components? It can’t without human attention, but a sorting utility helps to reduce the number to a manageable size.

Additive manufacturing is a solution for repair and replacement components—an application the U.S. military is very interested in. But which legacy parts make the most sense for transition to AM? The Defense Logistics Agency turned to government consultancy firm LMI for help with engineering a system that could identify additive candidates among the millions of parts it oversees.

In a presentation about this project at the most recent Additive Manufacturing Conference, LMI senior fellow Thomas Parks explained that completely automating the selection is not possible. The inconsistency of available data on military parts (many more than 50 years old) precludes this. However, material and dimensional data generally are available, and this is enough to get close. LMI developed a prescreening tool that filters parts according to their use of established 3D printing materials and their ability to fit within typical 3D printer build envelopes.

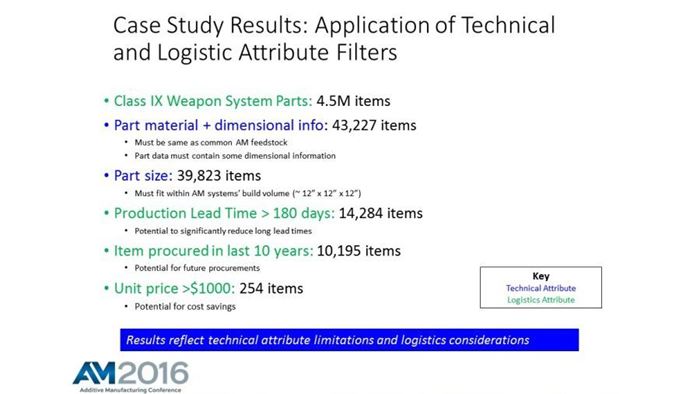

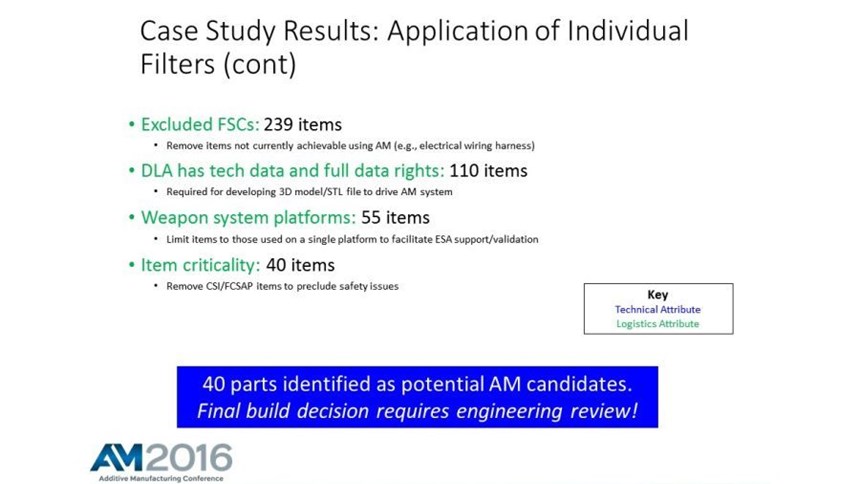

In a case study Parks described, the tool was used to find weapon system repair parts that would make the very best candidates for transition to AM. The initial universe of these parts is 4.5 million, too many to grasp. The filter by AM material and envelope reduced the number to about 40,000. That was still too many, but the user in this instance then used the tool to further limit the search to parts that are critical and expensive; have long production lead times; and have been ordered in the last 10 years. All of these requirements together reduced the list to 40, a small enough pool to let engineers evaluate parts one by one. These 40 out of 4.5 million are not by any means the only parts that might be made additively, but they are the ones for which the shift to AM is liable to deliver the largest immediate value.

Related Content

-

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

-

The AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

-

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.