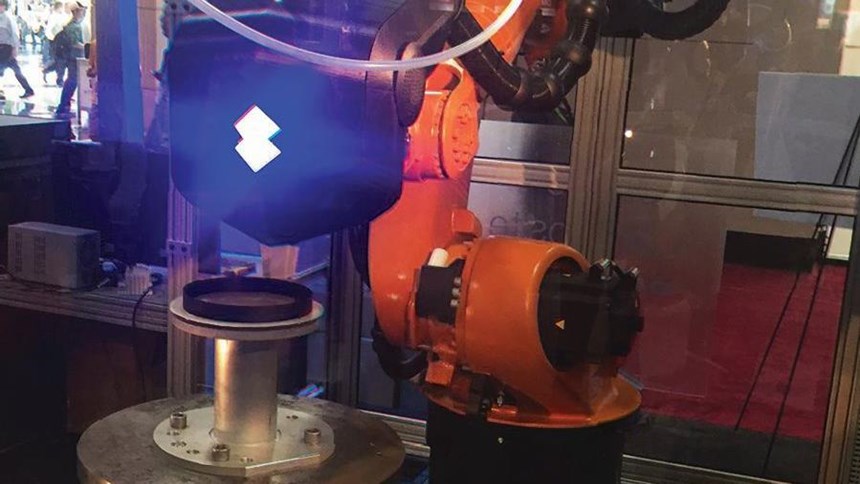

Eight-Axis Robotic System Prints Composite Parts

This concept machine leverages robotics to 3D print in eight axes.

At the recent International Manufacturing Technology Show (IMTS), 3D printer maker Stratasys demonstrated two concept machines that illustrate how the company is rethinking machine design for the use of 3D printing in production. One of the machines (not shown) is the company’s so-called “Infinite Build” demonstrator, which prints in a horizontal orientation to enable the machine to build large parts with the Z “height” limited only by the floor space the user of such a machine might devote to it. An upright platen receives the first layer of the part, then backs farther and farther from the deposition head with each new layer until the build is done.

The other concept machine is the one pictured above. The company’s robotic composites demonstrator employs a Kuka robot, a pivoting rotary table and control by Siemens to achieve eight axes of precise motion to generate lightweight, rugged production parts from carbon-fiber-filled plastic material. One of the advantages of this design is the ability to now 3D print not just in parallel layers, but in any direction around and along the part as it is being formed. Photos in the slideshow show the IMTS demo, as well as a component that was made using various deposition directions to enhance its strength. Read more about these 3D printer concept machines and see this commentary for more.

Related Content

-

The Robot Craftsman: Force Sensing and Vision Help Realize Automated AM Postprocessing (Includes Video)

Automated production via additive manufacturing will need automated postprocessing. This UK startup is equipping robots with the capabilities needed for critical, fine-detail finishing of metal 3D printed parts.

-

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

-

Video: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.