Share

Read Next

Peter Zelinski, Fiona Lawler and I attended RAPID + TCT 2023 earlier this month in Chicago. The event featured nearly 400 exhibitors within the West Building of McCormick Place, highlighting new materials, equipment innovations, and promising applications for additive manufacturing. From our conversations with exhibiting companies and attendees, we identified six major themes in evidence at this year’s RAPID, which we discuss in this episode of the AM Radio podcast (along with some of the fun and eye-catching things we saw on the show floor). Listen to the conversation above, and scroll through for photos and video of what we saw.

Transcript

Stephanie Hendrixson 00:05

Sustainability, process monitoring, additive winning on cost, DED and so much more in today's episode about RAPID + TCT. What we saw and what we learned at the 2023 event coming up on AM Radio.

Jodee McElfresh 00:26

This episode of AM Radio is brought to you by Formnext Forum Austin, the first of a series of Formnext events coming to the United States. Find more information at formnextforum.com.

The 2023 edition of RAPID + TCT took place in the West Building of Chicago’s McCormick Place, hosting nearly 400 exhibitors.

Stephanie Hendrixson 00:40

Welcome to AM Radio, the podcast where we tune in to what's happening in additive manufacturing. This time that's going to be all about what we saw and heard and learned at RAPID + TCT 2023. Before we get started, I want to just give a big thank you to all of our subscribers to AM Radio, many of whom we got to meet at the show. And welcome to our new subscribers. We're really happy that you're here. I'm Stephanie Hendrixson and I'm joined in the studio today by Pete Zelinski. Hi, Pete.

Peter Zelinski 01:05

Hey, Stephanie. That's right. We were at RAPID, we will talk about the things we saw there.

Stephanie Hendrixson 01:09

And for the first time on the podcast, we have a new voice, Fiona Lawler, welcome, Fiona.

Fiona Lawler 01:14

Thank you, Stephanie. I joined Additive Manufacturing Media in January as an associate editor and I'm excited to reflect on RAPID + TCT 2023 in this upcoming podcast as it was my first ever trade show with the team.

Peter Zelinski 01:28

So yeah, RAPID + TCT. Everyone calls it RAPID for short, we were all over the show. It was in Chicago this year, we saw a lot of things, talked to a lot of people. There's no way to account for it all in this episode. But there are some big themes that we saw. And I and we're going to talk about that.

1. More Sophisticated Ways of Thinking About Sustainability

Just to jump right into it. One of them, I think, is this increase in the range of material options specifically related to sustainability coupled with more sophisticated ways of thinking about the conjunction of sustainability with additive manufacturing. Here's a quick example of that I saw. Caracol is a company that their technology is applying robots to do deposition 3D printing in a large format, make big parts, and the demo they were showing had to do with making new wind turbine blades out of old wind turbine blades. Used wind turbine blades is potentially a large source of waste. So Caracol is involved in this R&D project with Enel, an energy company based in Rome to grind up glass-filled material used in some turbine blades to make smaller wind turbine blades that might be used, say in urban areas. So sustainability, materials, more sophisticated ways of thinking about sustainability. What else did we see in that theme?

Stephanie Hendrixson 02:50

I saw another example of a way of recycling some type of waste back into the 3D printing process or into other types of processes. So if you notice the Thermwood booth during the show, they had one of their big printers there. Large scale additive manufacturing, LSAM, and they were actually running it, they were making chairs all throughout the show out of this green material.

Peter Zelinski 03:11

It was hard to miss the green chairs.

Stephanie Hendrixson 03:12

Thermwood 3D printed chairs during the show using SABIC's LNP Elcrin WF006NiQ resin made with post-consumer PET.

It was really hard to miss the green chairs, but I learned a little bit more about that material that they were using and it's actually pretty cool. So it is something from their Elcrin iQ line. And Elcrin refers to this upcycling process that SABIC uses to take post-consumer waste, and turn it back into usable resin. So it's a chemical depolymerization process. So they're able to take single use PET, so stuff like water bottles that you might throw away or throw in the recycle bin, and break them back down and repolymerize it into a different material called PBT. So this is really cool because you don't have the same type of degradation that you might get from taking the same waste, grinding it up and like repelletizing it. Because they're breaking it down, they are able to preserve more of the material properties and get a better material at the end of it. So that green resin that they were using is a 30% glass fiber reinforced PBT material, and it was 25% post-consumer recycled content. So a really cool way of taking this post-consumer waste and getting it back into a format that it can be used to make new things like chairs at trade shows.

Peter Zelinski 04:22

I guess I want to mention in this context, real quick, Nexa3D and and we'll come back to them again, I think, later because we're going to talk about process monitoring, but within the context of recycling and sustainability. So they were showing their selective laser sintering machine QLS 236 is their is their branding for it. And the thing about it is, it is this open platform machine, a lower cost selective sintering machine and the idea they were showing for this machine is its applicability as a way to get some further use from end-of-life powder that's no longer good for other machines. 3D printing with end-of-life powder from other SLS machines, but they were also showing some cases of 3D printing from end-of-life powder from Multi Jet Fusion, a different 3D printing process and the exact mechanism of this I talked out a little bit, I think I only partially understand it, but the parameters can be set, so this, this material where its properties, most notably its coloration has degraded to a point, it's not as effective in Multi Jet Fusion anymore, you can still get some parts out of it by printing with this SLS machine.

Stephanie Hendrixson 05:38

Uniformity Labs’ materials for laser powder bed fusion contain a mix of particle sizes, allowing for more dense packing in the build envelope and ultimately faster printing using less energy. These brackets were on display, alongside impellers and other application examples.

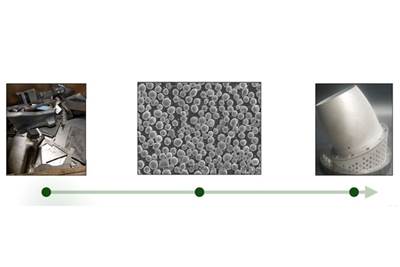

Yeah, so that's interesting. I feel like we don't hear a lot about what happens to the powder that you can't use. Like, I know you can recycle it and mix it up to a certain point. But it's cool that there is a new option for how to print with it. Fiona and I actually saw something kind of related to that on the metal side. So we stopped in at Uniformity Labs and talked to the CEO and founder Adam Hopkins. And what they're able to do is use what they call the cut-off stock from gas atomization. So somehow, they are able to take the metal powder that would typically be too big or too small for laser powder bed fusion and process it in a way that you can now use it for laser powder bed fusion to pretty great effect.

Fiona Lawler 06:20

Right, Adam talked a lot about the issue with particle size separation of these dense powders in terms of both flowability and processability. With the Uniformity Labs high density powders, overall, there is a reduction in residual stress across materials and the platforms in which the laser powder bed fusion printing process takes place. What does this look like? Ultimately, it means more efficient printing when utilizing less energy. Some more benefits a more evenly heated powder means faster printing, less overheating, remelting and melt vaporization means fewer supports are needed during the print, which can save materials, reducing waste and ultimately lessens the need for post processing. What I found really interesting was that Adam said that overall, the goal is getting the most out of the powder feedstocks.

Stephanie Hendrixson 07:09

So yeah, like this was a really interesting conversation, it went by really fast. But the way that I kind of understood it is the powder is packing more densely like sort of because of the variety of sizes that are represented there. And so you have more powder on your build platform more, more powder in the bed. And as the laser is melting, point by point, like there's just more powder that's kind of falling into that melt pool, cooling it down more quickly. And so you're melting more material with each pass of the laser, your energy is going to go further. And you don't get like the over melting-type problems that you might with a different type of powder. So that's kind of how they're like saving energy and speeding up the process. So again, like base level understanding, but I thought it was really interesting both for the ways that they're saving some of this powder that might be waste otherwise, and then also the way that they can improve the efficiency of the printing process.

Peter Zelinski 08:05

More and more and more efficient use of powder is one of these factors that is, that is working to bring unit cost down for additive manufacturing.

Stephanie Hendrixson 08:13

Yeah, and I think we're gonna get there later. One other thing that I want to mention, while we're talking about sustainability is just that I noticed a lot of new material launches at this show. So I'll just quickly kind of mention these. I talked with Xtellar, which is a spinout from Braskem. And it's sort of their materials company that's now just focused on serving the additive manufacturing market, they were introducing a number of new things, including an EVA, which is made from sugarcane, and this is a flexible material. It's sort of a TPU alternative, and the one that they were showcasing at the booth is clear or transparent. And you can sort of get different results by the way that you print it. We actually did a video about that which we can link in the show notes.

And then the other one that I'll mention real fast is that Jabil launched its PLA 3110 P which is a PLA powder. So this is a kind of really unusual material offering, but it was an opportunity that Jabil saw to provide an alternative to other materials like PA 12 nylon. PLA, it's made from castor beans, and they developed it actually with NatureWorks which is really well known for its castor bean-based material called Ingeo. Jabil is launching this as an option for producing casting patterns for thermoform molds, for prototyping and education. I talked with Luke Rodgers and Jesse Sumstad there and one of the points that they made is like as new engineers are learning how to do 3D printing, like they can generate a lot of waste, which is something that I talked with Tim Simpson about very recently on this very podcast. And so this PLA powder is a way for them to maybe get more familiar with SLS without worrying so much about the environmental impact of the material.

Fiona Lawler 09:55

Stephanie, I'm curious, where is the idea coming for experimenting with these otherwise maybe odd choices, sugarcane and castor beans?

Stephanie Hendrixson 10:05

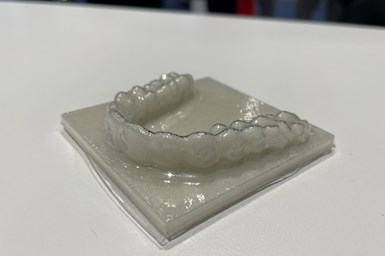

One potential application for Jabil’s PLA3110P powder for SLS is the creation of thermoform tools, like this mold for a dental mouthguard. The powder is based on Ingeo, NatureWorks’ product derived from castor beans.

Oh, good question. I don't know if I have the entire answer to that. But I think there's a couple of things happening here. Biobased polymers like this are not necessarily new. They've been used since at least like the mid-twentieth century. But I think what we're seeing happening is there is an increased interest in these types of biopolymers. Because we're all starting to think more about sustainability and the circular economy and like, what's going to happen to these materials after they're used? And where are they coming from in the first place? I think there's been an uptick in their popularity just overall. And then I think we're starting to see them enter the 3D printing space more than they ever have in the past, also, partly just because 3D printing is a brand new market for materials. And so as companies are starting to develop these different grades and formats of their polymers, it's maybe not that much of a leap. And so we're seeing more of these options coming into the additive space.

Peter Zelinski 11:00

Here's what I can connect to that. So I was talking to EOS’ head of sustainability. His name's Bjorn Hannappel, what EOS was showing is PA material. And one of these selections is a biobased material. But PA material that is sort of precertified in terms of its environmental impact, its carbon impact. And so EOS was showing its PA 12 material, it has 45% lower carbon footprint than comparable material, that material is petroleum based. And then there's a PA 11 that they certify as climate neutral, and that's the biobased material. And these materials are on the face of it more expensive than comparable materials. But from another perspective, they're cheaper if what you would have to do is certify on, through your own efforts, the environmental impact of the material you're using. EOS in these cases of these materials has already done that, and can supply that documentation. And so the premium according to Bjorn, I believe he said like for the PA 11 material, about one Euro per kilogram more expensive for this material to get that sustainability-related performance.

Another really interesting thing, different thing, EOS was showing, they, they're showing their sustainability calculator, and this is in beta. And this to me, Stephanie, connects to the conversation you and Tim Simpson had recently on this podcast about additive and sustainability, how there's a lot of relativeness in the evaluation of that and a lot of uncertainty about documenting the aspects of a process's carbon footprint. So EOS has this calculator that's really granular and asks you lots of questions about your process. What machine are you using? What powder? How was your powder made? How was it shipped? How far did it go? Things like that. Along with this matrix, the calculator itself is very open about as far as how confident it is in the numerical information it supplies in answering these questions. There are some things where the, the carbon performance EOS knows specifically, there are other things it's, it's deriving from academic papers. There are other things where they're making reasonable guesses. But it is this tool still in development for if you are choosing additive, in part to meet carbon footprint-related targets. This is a way to demonstrate to yourself or to others, the extent to which you are actually hitting those targets.

Stephanie Hendrixson 13:40

That's great. So yeah, one of the points from that conversation with Tim Simpson was just like how there, there are tools out there for how to do this. But like none of them, as far as I'm aware, have been really tailored for additive manufacturing. So it sounds like EOS has kind of taken that on.

Peter Zelinski 13:55

Okay, we could talk about this a long time, should we pivot to another topic.

Fiona Lawler 13:58

I think it's a good time to pivot. Next up, we're going to talk about cost as a driver for AM production.

2. Cost As a Driver of AM Production

Peter Zelinski 14:04

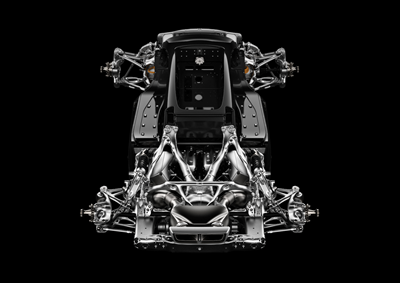

Additive manufacturing as the cost effective production process, including for products and parts that are already being made today. So that was a theme that kept coming up. It actually started from the very beginning of of RAPID this year. So the keynote was by Kevin Czinger, CEO of Divergent. This company developed the Divergent Adaptive Production System. Kevin talked about that in his presentation, and among other things, it provides this cost effective way to make vehicle chassis components using additive, but not totally because of 3D printing. As Kevin phrased it, we get the cost out in design in his words. That includes getting the cost out in assembly after the 3D printing by designing so that assembly can be fixtureless. So this whole system that Divergent has developed, it takes what is on its surface, a slow process compared to automotive production, metal 3D printing. But through part consolidation and automation and tooling reduction, it turns it into a cost effective platform for production. So according to Kevin and Divergent, they will be building tens of thousands of vehicle frames by 2025. Their market for now is vehicles that are $100,000 and above, which candidly, does not describe the car I drive, but that alone is a big market. It's a, it's a $5 billion market, according to Kevin Czinger. And the way this, this manufacturing will be delivered, it will, it's a proprietary system and will be delivered through Divergent's own factories. And this is a model we're seeing more and more of just as an aside, but reporting that Additive Manufacturing Media has coming up, it focuses on various examples of this, ways that additive technology is being deployed through new types of contract manufacturers.

Stephanie Hendrixson 16:13

Oh, yeah, so new types of contract manufacturers, I think I met one of them at the show. So I talked with AJ Strandquist, who is the CEO of Würth Additive Group. And so Würth, the parent company is a premium supplier for manufacturers is kind of how they describe themselves. They supply lots of different consumables, fasteners, tools, chemicals, all kinds of things that you might need for large scale manufacturing. And now they are also supplying the 3D printing industry as well. So you walk in their booth, and there are a number of different 3D printers in there, who they represent. If you want to buy equipment from them, you can do that. But I learned that in addition to supplying equipment for 3D printing, they're also using 3D printing to deliver inventory to their more conventional customers now, so they have found that 3D printing is the perfect opportunity to convert some things that they would typically keep in physical inventory into digital inventory. So they had a part,

This automotive clip is representative of one of the items that Wurth Additive Group can now 3D print and store in digital, rather than physical, inventory.

several bins of this part sitting around their booth. It was like this little automotive clip. And it's one of these things that they sell for aftermarket purposes. But it's the type of part that the original equipment manufacturer, the OEM, might not see any value in continuing to produce and hold an inventory. There's just not that much demand for it. And because Würth is able to make things like this through 3D printing now, their customers actually have like a new source of revenue for these spare parts, these replacement parts that might be needed in such few quantities that it wasn't really worth the time to tool up or to maintain a stock of these products. So now they can store files in the cloud. They can 3D print these as they're needed, and their customers can make money off of something that they previously weren't selling at all.

Peter Zelinski 17:59

Okay, cost is a driver for what's happening in additive. So a major machine introduction at RAPID. DMG MORI, they introduced their Lasertec 30 SLM US selective laser melting machine. Presenting was the U.S. president Keiichi Ota and DMG MORI's Nils Niemeyer, Fred Carter. And they talked about this machine developed in the U.S., manufactured in the U.S. at, at DMG MORI'S Davis, California, plant and part of the way this machine gets to a lower cost per part for parts made on this platform is rather than multiple lasers for, for higher productivity, this machine uses one big laser, it is a 1.2 kilowatt programmable laser and it is able to alternate between a ring laser configuration and a single spot laser. The system that governs it, DMG MORI calls it ABC, their adjustable beam control.

Fiona Lawler 18:57

So in this case, how is a single laser more cost effective than having multiple going at the same time?

DMG MORI’s Lasertec 30 SLM US selective laser melting machine reduces part unit cost in part by using just one cost-effective laser.

Peter Zelinski 19:02

Right? It's straightforward in this case, the laser itself is a pretty significant portion of the cost of the machine. So one laser, lower machine cost and that means lower capital equipment cost that has to be amortized through each part that's made on it. So Nils Niemeyer with DMG MORI said a couple of interesting things about the machine. One is the expectation and the aim of additive going well beyond aerospace and medical where it's well established now. He sees more general engineering applications of a lower price point. Laser powder bed fusion machine like this one for DMG MORI is already using it in production. They are making CNC machine tool components on this machine and one of those parts was there at RAPID. He also just noted as far as the U.S. origin of this machine and it being made in the U.S., he just noted how in, in general, and it's a generalization, but in general, U.S. manufacturers are just bolder in adopting additive. In other parts of the world, there is more a culture of a lot of care about analysis and hoping to identify all of the unknowns before proceeding with a huge new process. And American manufacturers are much more willing to move forward with additive and refine it and figure it out and master it as they go.

Fiona Lawler 20:29

Fabrisonic’s SonicLayer 1600 combines ultrasonic additive manufacturing (UAM) with CNC milling. The machine’s compact footprint reflects demand from customers for lower-cost, smaller machines.

Getting lower cost per part, because the machine itself is less expensive, reminds me of two other companies that I met with at RAPID. The first, Fabrisonic. So I spoke with CEO Mark Norfolk, he's seeing a big customer demand for smaller machines. That's because these are more affordable. At the first day of RAPID, they launched their SonicLayer 1600, which is a hybrid manufacturing and fabrication machine. And this enables additive and subtractive manufacturing and is smaller than their other machines per customer demand. Another company following this trend was Formlabs where I spoke with Kyle McNulty production lead, and he showed me their Form 3B+, which is an advanced 3D printer. And it's actually intended for healthcare professionals and medical device engineers. So this is also a smaller and more cost effective option.

Peter Zelinski 21:27

So yeah, that's interesting, because the companies that are deep, deep, deep into additive production, we are accustomed to them pushing for always bigger machines, because they can make bigger parts or get more parts in the build. But yeah, in terms of additive doing more reaching, more applications and getting cost per part down, in some cases, there is this need and this demand for smaller platforms as well. That's sort of an interesting tension.

Fiona Lawler 21:52

Maybe ultimately, in additive's space, bigger is not always better.

Peter Zelinski 21:58

Here's one more quick example of additive manufacturing, lower cost per part. We did a video about this we'll link to. I saw this in Trumpf's booth. And I talked for a little bit with Trumpf's Christian Lengwenat who's an application engineer for the company. We were looking at this 3D printed titanium mountain bike brake lever. If you've ever ridden a bike, ridden a mountain bike like you've seen this component, the thing your fingers squeeze to apply the brake. Carbon fiber, to some extent, is moving out of bike manufacturing because of the high carbon footprint. Machined aluminum is coming back, except in this case, Trumpf had the chance to say don't machine this part, don't do aluminum. Let us 3D print it from titanium, it will be cheaper. And they were right. In this case, they showed this build, you can get 280 pieces in one build, 3D printed all those parts in less than a day. So 280 pieces per day and the unit cost works out to $9 per brake lever for this 3D printed titanium version where the machined aluminum one was going to come in for this bike manufacturer at $15 per part.

3. Process Monitoring for Production

Let's open up a new topic and talk about process monitoring for production because it's another case where I saw kind of a smallish machine being applied to production. Nexa3D introduced their XiP Pro machine. And so this is their desktop, LCD-based, vat polymerization machine, scaled up into a larger system that's, that can be used for part production, except it's not that big. It's still, it was sitting on a table. It's still a smallish machine. But one of the features the machine had specifically with production in mind, they called it the “weather station,” is this readout connected to various sensors that are monitoring resin temperature, chamber temperature, ambient ultraviolet exposure, the humidity of the ambient environment, all these factors, so that if you're doing production on this system, you can lock in a window of what you think is the acceptable range for each of these parameters. And if any of them according to the weather station has strayed out of that acceptable range, you know you need to do something before production continues.

Fiona Lawler 24:27

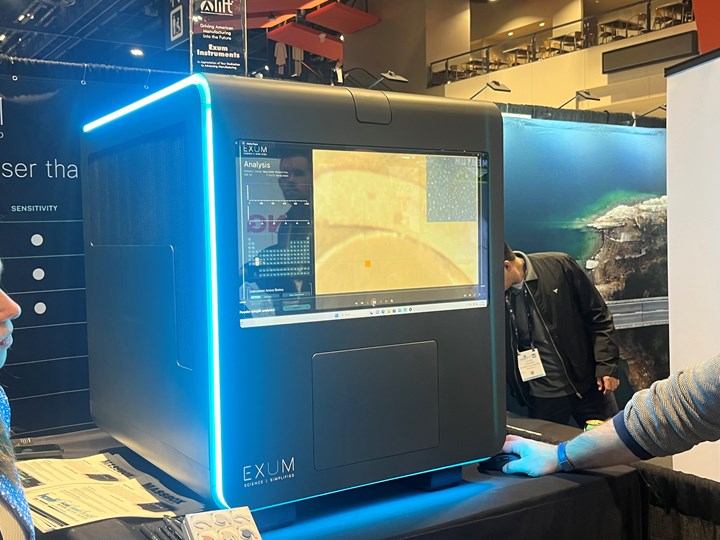

I saw another cool offering for process monitoring, and this is more of an accessory to 3D printing. It's the Massbox by Exum. The Massbox is a mass spectrometer tool. And it is used as an analytical technique to measure the mass to charge ratio of ions. I spoke with chief development officer Ellen Williams, and she explained that a lot of this measurement for materials testing is usually done in a laboratory environment. So the Massbox is in a way, effectively cutting out the need for the middleman in terms of going to the lab, doing testing there. Instead, you could get results in minutes without having to run to the lab, without having to wait. It can be used for solid sample analysis, and you can test pelletized powders. But this is also a great method to obtain feedback. So you can do this in the form of failure analysis for if some reason like the material doesn't deliver desired results, or something in a print goes awry, you're able to test for what might have gone wrong on the material science side.

The Massbox from Exum Instruments offers mass spectrometry in an easy-to-use tool that can sit on top of a table.

Peter Zelinski 25:33

Can I ask about this real quick because this is a new type or class of device than anything I've seen before. Like just real simply, what does it look like to use it? Like what are you putting inside of it?

Fiona Lawler 25:45

The Massbox can analyze the chemical make up of small parts, tensile bars and materials. These powder samples have been pressed together without binder. The sample plate represents the approximate footprint of the system’s analytic field.

So Ellen showed us a plate that was about five inches by five inches with a couple of smashed penny-sized pellets which can be inserted into the machine. For reference, it is a smaller machine going back to our talking about smaller devices in the AM space, it can also fit on a table. So this tool was designed specifically so that one doesn't need per se a chemistry degree to obtain the material science side of data for 3D printing. It's just one less thing that the scientists might have to do when experimenting and testing different materials.

Peter Zelinski 26:18

Okay, controlling your process with an accessory and not needing a lot of specialized skill. So another example of that that I saw, Renishaw was showing this. Renishaw makes laser powder bed fusion machines. They didn't introduce this unit at the show, but, but they had it on display at RAPID, and it is this calibration device for selective laser melting machines. I talked to Kevin Brigden about this with Renishaw. Renishaw was a metrology company long before it was an additive manufacturing company, metrology equipment for controlling the precision of CNC machine tools. And this is like machine tool thinking brought to additive.

This array of mirrored balls makes it possible to calibrate a laser powder bed fusion machine in just two minutes; lasers reflect off of the 169 balls to check for drift.

So this calibration device, it is this array of I believe, 13 by 13 mirrored balls. And you put this build plate full of mirrored balls into the machine and lasers reflect off of it. And it allows for a two-minute calibration process. Kevin says actually, in real practice, they probably do it in more like 10 minutes because they do successive calibrations and iterate as they go to get it more precise. Your laser doesn't, its positioning doesn't get out of whack all that fast in laser powder bed fusion. But what this calibration unit really helps with, Kevin said, is a multiple laser machine and assuring that a little bit of change in one laser and a little bit with another doesn't sum to a significant amount of drift from one laser relative to the other. So it used to be that this calibration would have been a two-hour process. And you, you make passes with one laser at a time on a mylar sheet that's inspected laser. So this takes that two-hour process and replaces it with something that's like two minutes, 10 minutes, something like that.

Stephanie Hendrixson 28:15

So all the examples of process monitoring that we've been talking about so far, it's more data gathering. It's checking that you're within the parameters that you expect to be in, that your machine is calibrated properly. And I think I want to take us into more like direct process management. And that connects to our next topic which is going to be directed energy deposition, or DED, right after this.

Jodee McElfresh 28:38

This episode of AM Radio is brought to you by Formnext Forum Austin, a new Formnext event coming to the US this summer. The conference and expo is organized by Mesago Messe Frankfurt, AMT — The Association For Manufacturing Technology, and Gardner Business Media, the publisher of Additive Manufacturing Media. Formnext Forum Austin is designed for leaders and owners of manufacturing enterprises, including companies already advancing with additive, and those getting ready to adopt it. It's also for engineers engaging with additive technology and researchers who are advancing what is possible for AM to do. The conference program offers three tracks: Production, powered by The Cool Parts Show; Design for Additive Manufacturing, powered by CIMP-3D; and, Technology, powered by Additive Manufacturing Media. The event also includes an expo featuring AM technology tours of local additive manufacturers and plenty of networking opportunities. And don't miss the finalists of The Cool Parts Showcase, a contest highlighting innovative 3D printed parts. We're currently taking submissions through FormnextForum.com, enter by May 30. Join Additive Manufacturing Media for Formnext Forum August 28 through the 30th in Austin, Texas. Find more information about exhibiting, attending or sponsoring this event at FormnextForum.com.

4. DED Getting More Precise

Stephanie Hendrixson 30:04

And we're back. I'm Stephanie Hendrixson talking with Fiona Lawler and Pete Zelinski about what we saw at the 2023 RAPID show. And just before the break, we were talking about process monitoring. And now I think we're going to shift into DED and some of the more direct process control things that we saw happening at the show.

Peter Zelinski 30:22

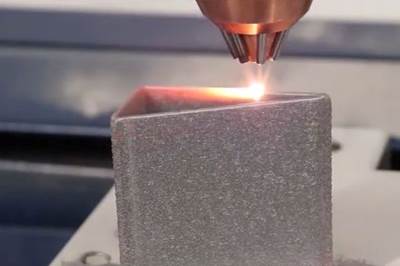

DED, directed energy deposition, DED is getting more precise, saw multiple examples of that at RAPID. So, MC Machinery introduced a new machine, this is their Mitsubishi AZ600 wire laser metal 3D printer, full five-axis machine, we've got video of it, that we'll link to in the, in the show description. But this machine is under closed-loop control of its metal deposition. So the wire feed, the laser power, the Z height, all of these are being adapted layer by layer in response to the machines measurement of the bead width and the bead height.

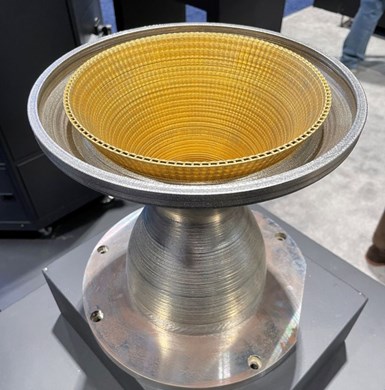

Another company showing very fine control over directed energy deposition is InssTek, Korean maker of DED equipment, in this case, their machine not wire fed, it's powder fed, and they have systems for very fine and precise powder feed control. And as a result of that, one of the results that InssTek was showing this multimaterial rocket nozzle, it's the first DED produced rocket nozzle to be made in Korea. And this nozzle had an Inconel 625 exterior and an aluminum bronze interior.

This rocket nozzle produced by InnsTek features an Inconel 625 exterior and aluminum bronze interior. The low melting point of this latter material is mitigated by conformal cooling channels 3D printed into the structure.

And the thing about that aluminum bronze, the melting point is something like 500 degrees Fahrenheit lower than the melting point for Inconel. So how can it stand up inside of a rocket nozzle? And the answer is it is DED produced, 3D printed with such precision that there are these very, very fine walls between coolant channels you look at this structure, we'll, we'll link to a picture of it. And the internal coolant channels are so big relative to the finely produced structure of it. It's like, it's, it's all cooling fluid on the inside. And combined with the thermal conductivity of the aluminum bronze structure it keeps this miniature rocket nozzle very cool. It was, it was recently tested as as part of an evaluation of a Korean produced rocket engine by the Korean Aerospace Research Institute.

Stephanie Hendrixson 32:44

And both of those materials were built with DED, like at the same time in sequence.

Peter Zelinski 32:48

That's right. I'm glad you asked that. Yes, another facet of InssTek's technology is the ability to integrate and control various different powder flows at once, not just two materials, I think their system allows for up to six materials all at the same time. So yes, this was 3D printed all in one cycle with the aluminum bronze layers and the, the Inconel 625. Layering, all done as part of one single 3D printing cycle.

Stephanie Hendrixson 33:19

That's pretty cool. So I want to jump in here because both of the examples that we've been talking about are process control built into the machine, right. And there was an introduction at this RAPID, which is sort of an add-on accessory that you can incorporate into your DED printer to allow for that kind of closed loop feedback without needing for that to be built into the system from the get go. So this is something I actually got a little preview of it before the show. But this company called New Infrared Technologies, they're based in Madrid, they specialize in infrared cameras, and they created this accessory that's called Clamir. It's an infrared camera that attaches like to the printhead, watches what's going on in the melt pool. And as part of the setup, you sort of define the melt pool width. So you say the melt pool should only ever get this wide. And if the camera ever detects that it has gotten too wide, that means the laser is too hot, there's too much melting happening. And it will actually power down the laser a little bit so that you stay within that target melt pool width and keep your DED printer where you want it to be. So they've worked with Trumpf and they've worked with a couple of other DED printer suppliers. Again, this is the first time that this accessory was, was shown or made available in the U.S. But it struck me as just like a really kind of simple and accessible way of incorporating this type of process control into DED without having to start from scratch with the building of the machine, for instance.

The Clamir unit can be see on the left side of this DED head (the orange box with camera lens directed into the meltpool). Photo Credit: New Infrared Technologies

Fiona Lawler 34:44

I'm curious, how big is this accessory?

Stephanie Hendrixson 34:46

So it's pretty small actually, like I didn't get to see it in person at the show. But from the photos that I saw in advance like I would describe it as sort of like a DSLR camera with a kind of longish lens like it sort of looks like that and it's attached to the printhead on your DED machine just looking straight into the melt pool.

Peter Zelinski 35:04

A couple other DED things we saw so Meltio, this one's in the category of, well similar to Clamir, making DED and and control over DED more accessible. So the Meltio engine, we saw this on a CNC machine tool at IMTS last year, did a video of that which we'll link to. At RAPID this year, this was the first US showing of robot integration with their, with their Meltio engine, taking a standard robot and turning this into a directed energy deposition metal 3D printing system.

And Formalloy had a machine introduction at the show. We've talked before about Formalloy's DEDsmart system, and we've got a video of that as well that we'll link to.

Stephanie Hendrixson 35:15

Also from IMTS.

Peter Zelinski 35:43

So now there's a wire fed version of the Formalloy machine with the DEDsmart technology in addition to their powder fed platform for DED.

5. Acquisitions As a Means of Diversification

Stephanie Hendrixson 36:03

All right, so lots of new options for DED and DED process control, I think we should move on. So the next big topic that I want to talk about is acquisition as a means of diversification. So we saw a couple of ways that this played out at this particular show. I mentioned Xtellar at the beginning in the first half. And Xtellar is a spin out from Braskem, which you might recall, acquired another company called Taulman3D. So I talked to Jason Vagnozzi, who is the CEO of this new Xtellar company about how and why that happened. So Braskem, the parent company, is very well known as a supplier of polypropylene for lots of different polymer processes. But as they started to get into the additive space, they realized they didn't just want to be the polypropylene company or the polyethylene company. So they acquired Taulman, so that they can widen their product portfolio. So that allowed them to add nylon and P-E-T and P-E-T-G, or PET or PETG. And now that they have spun out into Xtellar, they're going to be able to focus more fully on offering different types of polymers, specifically for the additive manufacturing market. So they are still going to be able to benefit from the labs and the materials knowledge of Braskem, the parent company, but they're not going to be burdened with as much overhead they're going to be able to be a little bit more nimble and flexible in the types of products that they're going to launch and bring to the additive space. So including that new flexible EVA material that we talked about earlier.

Peter Zelinski 37:33

I guess speaking of acquisition, you got to spend some time looking at Markforged's now binder jetting technology.

Stephanie Hendrixson 37:41

Yeah, that was a super interesting conversation. So Markforged acquired this company called Digital Metal, which had been developing binder jetting technology for its own use, like they were a parts producer. That's why they they created these machines. But I got to talk with Ross Adams, who is the head of business development for Digital Metal, and Christian Lönne, who's the CEO of Digital Metal. So this particular RAPID was the first time that the PX100, which is the binder jet machine, was on display in the Markforged booth. Got to learn a lot about this machine.

Christian Lönne (right) speaks at RAPID + TCT 2023 about the Digital Metal PX100. Ross Adams, Markforged head of business development for this machine, looks on.

But maybe the more interesting part of the conversation was just why Markforged decided to go this route. So binder jet is great for making lots and lots of small metal parts. And that's sort of something that Markforged wasn't really able to provide to their customers up until this point, their polymer, their composite printers are very commonly used for jigs and fixtures for robot tooling, end of arm tooling, that kind of thing. The Metal X platform is getting a lot of traction in tooling and prototyping for other types of metal processes. But now with the addition of this digital metal binder jet platform, they can now serve the customers that want to 3D print lots and lots of metal parts. This was something that a lot of their Metal X customers were interested in, like they wanted a higher volume option. And now they're actually able to get into spaces and industries and OEMs and types of customers that they haven't previously been serving with this type of solution.

Peter Zelinski 39:13

Okay, acquisition as a means of diversification. I guess I saw a couple examples of that myself. So 3D Systems, a prominent part of their exhibit was their big Titan Robotics machine was there making stuff, this polymer deposition machine, pellet fed. I talked to Brad Mount, he's 3D Systems’ global director of business development. 3D Systems acquired Titan Robotics last year, which is how they got this, this big FFF-style machine. They were showing it in hybrid mode. So it's polymer 3D printing plus machining all in the same build. Pellet fed, like I mentioned, Brad says, like pellets because that's the cheapest to get. The machine can also do filament-fed material, but an advantage of the pellets is what, what came out to me in talking to Brad is the freedom it allows for material development, including proprietary material development. And I saw some specialized ducts that a customer was making. This customer needed ducts made out of a very strong ESD material. And they develop that material themselves and now are, are finding the solution they need through this, this pellet material they made themselves and are applying on this machine. Duct work, like big parts. But there is, according to Brad, an even stronger, potentially, tooling application for this machine. For example, thermoform tooling they're seeing as, as huge on this platform. Companies using it for thermoform tooling are getting something like 80% cost reduction and 65% lead time reduction for tooling made this way versus if the tooling was machined out of a machinable polymer during COVID. According to Brad Mount, one of the markets that took off was recreational vehicles and companies in the space were 3D printing thermoform tooling just for the sake of getting the tooling fast, they would be happy if they could make 200 parts with it. But he says this tooling is proving very resilient, and much of it is still being used for many multiples of that number of parts.

Totally different acquisition scenario that I also saw and had a chance to talk about. This was a show where UltiMaker was showing its new branding, I talked to the CEO Nadav Goshen. Ultimaker merged with MakerBot last year. And so now, the way that is being presented this, this combination of these two different companies offerings, the new UltiMaker now divides this products between what it calls its S series and its Methods series machines. And the Method series has actively heated build chambers, direct drive, rigid metal frame. So these are sort of production-ready machines. And so the, what diversification or a merger brought to this company, UltiMaker now is this path from desktop 3D printers for prototyping and engineering work up to making end use parts.

Stephanie Hendrixson 42:21

So that's interesting. Like I remember when that merger happened, it seemed like sort of two competitors coming together. But what you're describing is they've really used this as an opportunity to expand their offerings, and have these two different lines that are sort of serving two different customers, but it would be potentially an easy transition from one to the other. But remind me what is the official branding now? What is this company called? And how are they presenting themselves?

Peter Zelinski 42:45

And as you ask the question, I've pulled them up on my phone to, to confirm this is true. Yeah, it's UltiMaker. But with that m, in the middle of the word capitalized now, as if to say, what used to be MakerBot is still in there, too. And still a powerful half of this new merged company.

Stephanie Hendrixson 43:03

That's an elegant solution. And I asked the question, just because as journalists, we spend a lot of time thinking about capitalization. So, having the clarity there is is useful for my own information.

6. Collaboration Among Suppliers (and Customers)

Peter Zelinski 43:13

I guess from mergers and acquisitions, there's kind of a graceful transition that could be made to collaboration and cooperation. Want to talk about that a little bit?

Stephanie Hendrixson 43:22

Certainly, definitely something that I noticed at this show. And I think it's been kind of an ongoing trend, like this recognition from suppliers that they can't exist in a vacuum, they have to be able to show how their solutions connect with, integrate with, work with other things in the additive manufacturing workflow.

Peter Zelinski 43:39

Yeah, you and I had a conversation with Stratasys, in which that was kind of clear that what they're aiming to do there, they're not selling 3D printers, they're selling solutions.

I guess as far as why we're talking about this and why it's so important in this space, maybe the clearest conversation I had about this was with Martin Back, he's managing director of BASF Forward AM Group. BASF independent material provider providing materials for various polymer 3D printing platforms and, and the way Martin Back talks about it, the customer-supplier relationship, and the way that that works, it's fine when the whole space is established, and how it works is very well defined. And everybody has the same understanding of that established definition. That's not the case with additive, which is a whole range of possibilities drawing on a set of technologies that are still advancing and still moving. BASF's response to this is at, it has created a solutions development team, that kind of, well looks for solutions to develop, looks for answers it can help push forward. So there are many, many needs, potential customer needs where it's absolutely not clear. Is this a machine challenge, is it a material challenge, is it a design challenge?

An example of this that BASF was showing, its Ultrasim 3D lattice engine, and the partner it had on developing this answer was, was Hyperganic. And so it is this lattice selection tool for part design. And you might want, you might want a lattice in your polymer component that gives you some particular level of springiness and hardness and density. And there's this whole matrix within this tool that you find that combination of parameters, and it quickly provides a lattice that meets that and it's not a way to get to a finished part. But it is a way to get to a part that is near enough to your final design that lets you print something and, and begin to experiment with something very close to what your final product might look like. So again, this is, this is a lattice design tool. It's not directly a materials development, but the material is in there and through collaboration, BASF, and it believes other, other players in the space just have to kind of broaden their reach, collaborate and own problems that have a larger scope than, than just their specific discrete piece of the process.

Fiona Lawler 46:21

So that kind of reminds me of what I saw at HP. Stephanie and I heard about a collaboration with Siemens, and it's part of their technology that can now tow the build units.

Stephanie Hendrixson 46:33

Yeah, so HP introduced a couple of automation options for their MJF printers at this show, one of which was powder handling, the other of which is an automation accessory. Basically, it's like a track that can pull the build unit out of the printer, kind of shuffle it off to the side and plug a new build unit in for you. But we also saw a video in their booth where they've collaborated with Siemens on an automated guided vehicle that can actually then come and grab that build unit and like drag it over to the postprocessing station and carry it on through the line without any sort of human interaction. So, I think that was a good example of how HP and Siemens have collaborated for multiple years now, kind of the latest iteration of that.

But thinking about collaboration, I think that the way HP works with its digital manufacturing network and digital manufacturing partners is also kind of an example of the type of collaboration we're talking about. So, Fiona and I also attended a lunch for press and analysts, where we got to meet Phil Arnold, who is the founder of Endeavor 3D. It's the newest member of the digital manufacturing partner network. And they are a user of Multi Jet Fusion, I believe they've also now got Metal Jet as well. And so this is a brand new company started from the ground up, started with the idea of being a contract manufacturer using 3D printing. And Phil talked about kind of making that decision and how they decided what technology to use. And part of it was HP's R&D capacity. Like they have all of this history in 2D printing, they have labs working on 3D printing, and that was a big part of it. But also being part of this production network with other manufacturing partners, many of whom we've talked about on this podcast, many of whom we visited, that was really appealing to them as a brand new manufacturer trying to get up to speed in this space. And just like knowing and trusting that they would have HP as a partner to work with them and help them figure all this stuff out.

7. Flavor of the Show

All right, so I think that covers the business side of this podcast. And I do want to spend a couple of minutes at the end here, just sharing what we thought was really interesting and eye-catching and neat.

Fiona Lawler 48:40

Yeah, so being that this was my very first trade show, I thought everything that I saw was cool. But I think the thing that maybe stood out the most to me was when I was at, visiting Xjet. So they had 3D printed ceramic wind mouthpieces for different wind instruments. They had a couple of variations. I got to see one of these mouthpieces being used and someone was actually playing the saxophone. So that was one of the coolest things I got to see.

XJet’s NanoParticle Jetting process was applied to 3D print these ceramic mouthpieces for wind instruments.

Peter Zelinski 49:07

What's the advantage of a 3D printed mouthpiece?

Fiona Lawler 49:09

Right. So, they actually tested these out with some famous musicians who play wind instruments. And the musician said that it just creates a really smooth sound.

Peter Zelinski 49:20

Very cool. Stephanie what caught your eye?

Stephanie Hendrixson 49:22

Um, so this isn't necessarily something that was like visually eye-catchy, but I went to the nTopology press conference. And at this press conference, one of the announcements was nTopology is now simply nTop, so they've embraced the name that we've all called them all along. Not to be dismissive of that or anything like there's a lot of new interesting stuff in nTop 4.0 which was also announced. But one interesting tidbit from that press conference is that nTop, along with the new name, they have a new logo, and they actually designed the logo in nTop.

Peter Zelinski 49:54

Alright, so flavor of the show, look of the show. Lots of drones and robots, like I think we could agree on that. Lots of drones in particular.

Stephanie Hendrixson 50:02

Oh, yeah, lots of drones. Xtellar had one of those Boston Dynamics robot dogs in their booth and it was dancing around following people.

Dive Design 3D printed accessories from Xtellar materials for this Boston Dynamics robot used for security services provided by autonated security company Asylon Robotics.

Peter Zelinski 50:09

Inkbit’s material jetting technology enabled by AI makes it possible to nest many parts into a single build volume. All the components seen here are for robot applications.

Davide Marini of Inkbit kind of talked about why this is such a good space for additive. Drones and robots are both manufactured at kind of the right production volumes. Additive manufacturing, polymer additive manufacturing is advancing in terms of the productivity it can hit and Inkbit is an example of this. But so parts are produced in lots of thousands, say, and lots of different components. So Inkbit's system, in particular, can do 3D nesting, and they showed this sort of like great 3D nested jigsaw puzzle of different 3D printed robot components that they're producing.

Fiona, you mentioned ceramics, I guess what that makes me think of, it's not something I saw, but an event like this gives you a great chance to have sort of future-looking conversations, and I had a conversation like that with 3DCeram Sinto’s David Diegel. He's their business development manager and he's talking about their, the work they're doing with ceramic 3D printing toward getting more compact circuit boards, 3D circuit boards we're used to right now in our electronics, the circuit board is always flat. Your smartphone is flat because the board is flat. But they're imagining a world in developing systems and working toward a time when circuit boards will be these three dimensional objects, like imagine a very complicated 3D form like Dungeons and Dragons dice, like your, your circuit board looks like that. They do SLA 3D printing in ceramics and in their system it's like they they deposit a conductive ink as they go to create a solid part that has the intricately winding around circuit board structure within that ceramic component.

Stephanie Hendrixson 52:05

So I feel like this is a little bit more basic, but I noticed like a greater representation of safety equipment at the show. So Wurth Additive right at the kind of the corner edge of their booth. They had a mannequin in like full PPE for handling metal powders, like respirator and everything. And like I can't say that I've seen that before.

One of the other exhibitors was BOFA and they offer different types of like air filters and filtration products for dealing with emissions from 3D printers. And they had this kind of cool display where they had a 3D printer, which wasn't running, inside of this enclosure with a fog machine that would come on periodically. And then they had one of their filtration units hooked up to it. And so the fog machine would run and then this filter would go and you could just see how quickly the enclosure would be cleared of the smoke, which is sort of you know, simulating the types of emissions and nanoparticles and all that other stuff that might be coming off of your 3D printer.

Peter Zelinski 53:01

Talk about the tensile test machine you played with.

Stephanie Hendrixson 53:04

Oh, yeah, so our booth Additive Manufacturing Media was almost directly across the aisle from polySpectra, which is a materials company. And they had like this tensile test machine rigged up in their booth that had a crank and you could just turn it until the sample broke. And there's a scale on there to show you how many pounds of force so I got to break a sample of their COR Alpha resin. It broke at 300 pounds, just over 300 pounds of force. And I did that right after they let me break a sample of another unnamed resin. I don't know what it was, it was white, that one topped out at around 200 pounds of force. So from what I understand this was a similar type of material, but I got a very hands-on experience of how one was stronger than the other.

Just before I broke a tensile bar made from polySpectra’s COR Alpha resin. The test topped out at 307 lbs of force (about 50% higher than the unnamed competing resin I broke first.)

Also polySpectra, their big launch at this show was their COR Bio resin, which is it's a really cool looking resin, it's actually green. And it's used for surgical guides, microfluidic devices, dental applications, the cool thing about it is that it can go through a steam autoclave. And so in order to illustrate that at their booth, they had a glass tea kettle and they just had like some of these COR Bio parts floating around in there and they would periodically turn on the kettle and you just watch them boil and nothing bad happened.

Peter Zelinski 54:14

So when the tensile sample broke in that machine, was it like really satisfying, or was it scary like a jack in the box?

Stephanie Hendrixson 54:22

So like they had a cover over it, which I was, I felt better about. It was, it was equal parts satisfying and startling because I can tell like the crank was getting harder to turn, but I did not have a good read on when the break was actually going to happen. So it was a little bit startling.

Peter Zelinski 54:41

It's fun. I want one for our office.

Stephanie Hendrixson 54:43

We should get one.

Fiona Lawler 54:45

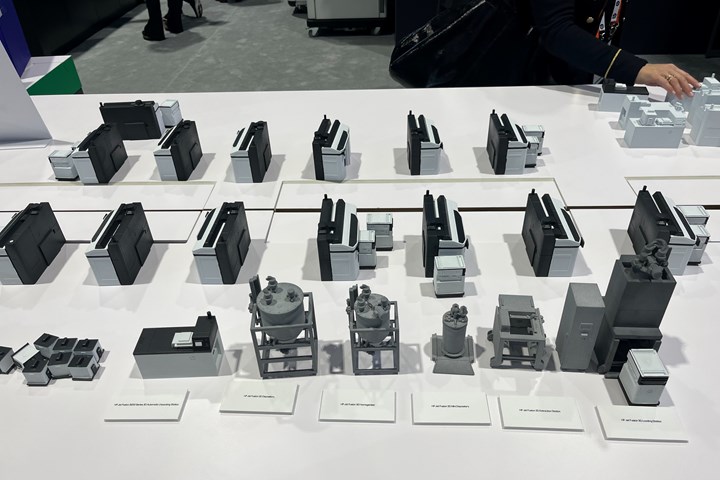

Another cool hands-on example that I got to see was at HP's booth and they actually had set up a mini, little factory on the table. And you could actually move around the pieces to kind of see the flow chart almost of the new automation technology that we talked about earlier. So this was great for maybe someone who is newer to additive like myself to just see the way that the process flows and ebbs and why this is helpful in cutting out human interaction.

HP demonstrated factory-scale automation using models of its printers and newly introduced options (including the 3D Powder Handling Automation Solution seen in the foreground).

Stephanie Hendrixson 55:14

I thought it was a pretty clever way of presenting what they offer for automation, because like the scale of it is bigger than you could put in a trade show booth. But by seeing like, here's the entire powder handling line, and like, here's how it moves from one end to the other, I thought was very clarifying and helpful for me even being pretty familiar with HP and their technology.

Fiona Lawler 55:37

We didn't get the opportunity to do much sitting, but when we did, there were some 3D printed chairs that were pretty comfortable.

Peter Zelinski 55:43

But that's the thing. There were a number of different chairs that were part of this, this show.

Stephanie Hendrixson 55:47

Yeah. So I started my Tuesday morning by sitting down in some very comfortable chairs at the Xtellar booth. We talked about the green chairs that Thermwood was making, which ones did I miss?

Peter Zelinski 55:57

So 3D Systems, the Titan Robotics machine, there was this very intricate 3D printed chair. We'll, we'll put a photo into the show description designed by Slicelab. Yeah, pretty cool 3D printed chair.

3D Systems’ lounge chair 3D printed on the Titan Robotics large-format FFF printer seen at the show. According to Pete, it’s quite comfortable.

Stephanie Hendrixson 56:11

All right. So that was a lot. We're gonna put links to everything that we talked about in the show notes. In the blog post on our website, we will have photos and video and all kinds of other supplemental materials. So check all of that out. But, I think we will end this episode here.

Peter Zelinski 56:25

Yeah, I guess one last note, we've been talking about an event and important trade show, RAPID + TCT. Another event, a different kind of event is coming later this year, we're helping to organize it. Formnext Forum will be August 28 through 30 in Austin, Texas. Join us there. So this is an event for manufacturers. It's about industrial production through additive manufacturing. It is a conference and an expo. As part of the conference, we have leaders with companies in oil and gas, in medical, in aerospace describing the transitions to additive production that they've made, how they did it, the challenges, how they've sustained it. So this event, conference and expo, like I say and also a lot of opportunities to meet and speak with the additive manufacturing leaders who will be part of our program. So go register, join us FormnextForum.com.

Stephanie Hendrixson 57:20

So we hope to see you in August at Formnext Forum Austin. If you like AM Radio, please subscribe on your favorite podcast platform, give us a five-star rating, tell a friend, tell a colleague about us. Thank you for listening.

Peter Zelinski 57:33

AM Radio is recorded with help from Austin Grogan. The show is edited by Jodee McElfresh and Stephanie Hendrixson. Our artwork is by Kate Bilberry Schrand. AM Radio and Additive Manufacturing Media are products of Gardner Business Media located in Cincinnati, Ohio. I'm Pete Zelinski. Thanks for listening.

Related Content

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreThe Cold Spray Solution to the Casting, Forging Supply Chains

Startup HAMR Industries performs additive manufacturing work at Neighborhood 91 that provides an alternative to traditional casting and forging. Success so far has led to redefining the limits of its additive equipment.

Read MoreHow 3D Printing Aids Sustainability for Semiconductor Equipment: The Cool Parts Show Bonus

Hittech worked with its customer to replace fully machined semiconductor trays with trays made via DED by Norsk Titanium. The result is dramatic savings in tool consumption and material waste.

Read MoreRead Next

Divergent Technologies Eyes High-Volume, Optimized Automotive Production Through Additive

While some automotive OEMs are using additive here and there, Divergent Technologies is basing its vehicles on 3D printed structures.

Read MoreSustainability in Additive Manufacturing Is a Moving Target: AM Radio #37

Assessing 3D printing as a sustainable manufacturing method is a complex problem. Dr. Tim Simpson and Stephanie Hendrixson discuss current research and future opportunities on AM Radio.

Read MoreInfrared Camera Supports Real-Time Process Control for Laser Metal Deposition and Cladding

New Infrared Technologies’ Clamir system provides continuous meltpool monitoring for cladding and directed energy deposition 3D printing.

Read More

.jpg;width=70;height=70;mode=crop)