For the co-founder of a manufacturing services provider that grew from 3D printing, Rich Stump is markedly measured in how he speaks about the technology and the role he sees for it within Fathom Manufacturing.

“I don’t want to oversell it,” he said, speaking as the company’s chief commercial officer when we met in June (he is now a technical adviser). “I’m a believer in using 3D printing in the places where it is profitable today.”

Rich Stump, co-founder and chief commercial officer at Fathom Manufacturing when we spoke in June 2023, sees bridge production as AM’s largest opportunity currently. The company aims to work with OEMs and startups as they develop new products, something Stump himself has experience with as the co-creator of the CaliBowl seen here. (He has since left the organization but still serves as a Fathom technical adviser.)

When Stump co-founded Fathom in 2007 as a 3D printer reseller, that profitable application was prototyping and most of the machines the company provided went into R&D labs for that purpose. But over the years, Fathom expanded to become a 3D printing service provider as well — ultimately selling off the distribution part of the business in 2018 and going all-in on the services side. Over that same timeframe, additive manufacturing has found greater adoption beyond prototyping as well, making its way further into tooling and end-use applications.

These advances have been reflected in Fathom Manufacturing’s application and adoption of this technology as well — it now operates nine or so different 3D printing modalities — but AM is no longer alone. That’s because along with leaning into manufacturing services, Fathom has been steadily acquiring other kinds of businesses, equipment and expertise beyond additive. Today the company operates more than 10 manufacturing locations, and AM is now one of the company’s four pillars, alongside CNC machining, injection molding and sheet metal fabrication.

This expanded offering reflects the diversity of materials and types of parts that customers need, as well as the specialty that Fathom has developed: fast turnaround on low to medium volumes of parts.

While machining, molding and forming account for a larger portion of the company’s production work and revenue today, additive manufacturing still has important (and profitable) roles to play in bringing customers in the door and quickly meeting their expectations. 3D printing is how Fathom delivers on next-day orders; how it provides spare parts for line-down situations; how it helps customers develop new products; and how it serves their bridge production needs before tooling.

Leaning Into Bridge Production

It’s this last use case that Fathom sees as particularly promising for 3D printing technology.

“The biggest opportunity for us and additive manufacturing is bridge production,” Stump says. Many of the parts the company delivers to OEMs for testing or initial product launches are made this way today. AM’s speed and flexibility in the face of potential design changes make it a capable choice to bridge the production gap while waiting for setup of a conventional process like molding or machining. (That full-scale production may or may not ultimately be performed by Fathom as well, depending on the quantity — the company’s sweet spot, Stump says, is in the hundreds to tens of thousands of parts.)

Leaning into this bridge production opportunity informs decisions about the types of clients Fathom takes on. Stump says the preference is to manufacture lower quantities of many part numbers, and form partnerships with clients who will need these services over the long term. “Where can we get wide?” he asks.

The business has come to focus primarily on serving OEMs that do a lot of product development (current customers in this vein include Tesla and Lucid) as well as startups with solid funding and growth potential. Additive is key to the kind of fast, responsive production that these clients demand — but it’s often not the only solution at work. For the kinds of high-mix work that Fathom sees, balancing pricing, quality, speed and expectations is frequently achieved with a combination of technologies.

In one recent example, Fathom Manufacturing produced components for a home robot that were needed quickly. In just 30 days, the company 3D printed 3,000 polymer parts directly. But in that same time frame, it also developed 55 tools for injection molded polymer parts, and produced urethane cast and machined components. All these pieces were then delivered to a contract manufacturer for assembly.

“We use the best process to solve the problem,” Stump says. “For critical, high-value applications AM makes sense and customers are willing to pay the higher cost. But for other applications, we can offer better material selection, repeatability or cost with different processes.”

Fathom’s recently implemented SVP platform from Evolve may shift the balance in favor of AM more often. The 3D printer makes use of NexPress technology that was created by Kodak for high-throughput 2D printing. Now, instead of laying down ink and toner, this machine applies layers of support material and injection molding-grade ABS. See the system in action in this video.

Adding STEP Technology

The bulk of manufacturing production, whether additive or conventional, happens at Fathom Manufacturing’s Wisconsin headquarters. This location is likely one of the largest AM service facilities in the U.S., with 90 3D printers as well as equipment for a number of conventional processes. On the AM side, Fathom offers metal part production through laser powder bed fusion (LPBF) and polymer parts through FDM, SLA, Multi Jet Fusion, PolyJet and SLS processes.

Now, there’s a new option for polymer 3D printing, one that is positioned to take on higher quantities and more of the work that might otherwise have gone to injection molding. When I met with Stump at Fathom’s newly established Technology Center in Fremont, California, I also saw the first commercially installed SVP system from Evolve Additive Solutions. This machine utilizes STEP, Selective Thermoplastic Electrophotographic Process, a 3D printing technique based on imaging technology originally developed by Kodak for high-volume 2D printing. The machine promises speed, part quality comparable to injection molding (and with the same materials), and competitive pricing for polymer parts.

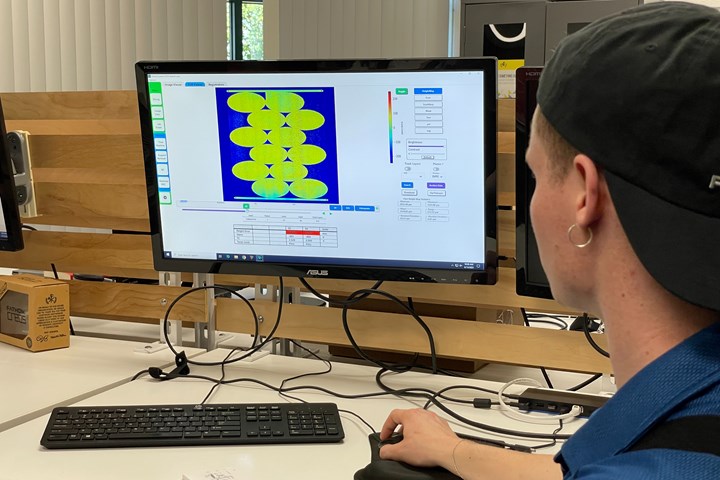

Matt Reich, an employee of Evolve Additive Solutions on site to implement the SVP system, describes how the machine prints parts by transferring ABS onto a roller and then to the build plate.

Inside the 3D printer, five independently controlled print engines can be equipped with up to five different injection molding materials. For now at Fathom, typically only two engines are in use at once: one for the black ABS that forms the part layers, and one for a soluble support material that reinforces the part and acts like a mold to define its edges.

The other engines can be devoted to different colors or materials; Fathom is currently experimenting with gray ABS applied in two-tone fashion with the black material.

As each layer is imaged, an infrared lamp heats the polymer material to melting so it can be picked up by a roller similar to printer toner. Then, the roller transfers the material to the build plate while applying pressure to fuse the polymer onto the layer below. Layers are just 13 microns thick and can be applied in less than 7 seconds. Each layer is then scanned to ensure the integrity of the build.

WATCH: See the Evolve Additive Solutions SVP printer in action in this video filmed at Fathom Manufacturing.

“Every image we capture is a topographic height map,” says Matt Reich, an applications engineer for Evolve Additive Solutions who was working on-site in Fremont at the time to integrate this system. That topographic map is automatically evaluated for high and low points. If any are detected, the 3D printing system will apply more or less material in the following layers to compensate, providing closed-loop control.

The round coasters being printed look warped in the topographic images as a result of the scanner’s resolution, but the bars on either end of the build feature holes that serve as registration points so that the scan data (and any necessary adjustments) can be matched to the part.

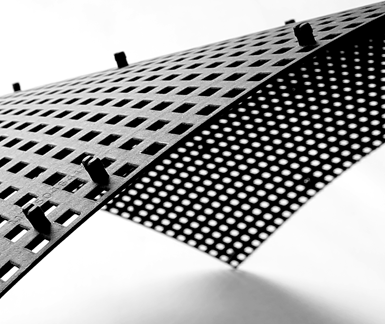

Each build inside the Evolve printer begins with 24 layers of support material which adheres to the substrate and creates a level bed for the parts. Parts are printed fully encased in the support material, at least 9 mm on all sides. Following 3D printing, the entire block of printed material is separated from the plate, and then washed with isopropyl alcohol (IPA) to remove the support material.

The ABS is printed encased in a secondary material that serves as both a support structure and a mold to help define the edges of the parts. Full builds might emerge as flat blocks if parts are of similar height, or with this support material contouring their upper layers.

For the kind of product development work and bridge production Fathom expects to do with this machine, its speed, surface finish and consistency are a good fit. Fathom is applying the platform for customers like Daktronics, a designer and manufacturer of electronic scoreboards and display systems.

The company came to Fathom in the course of developing a new LED panel for a racetrack-style scoreboard. Injection molding panels for the display’s curved corner sections would have required multiple complex tools with two lifters for each of the panels’ clip features. Obtaining the necessary tooling would have taken up to 16 weeks overseas or up to 19 weeks domestically.

The curved corners of the scoreboard need complex panels that would have required multiple complex and highly automated injection mold tools. Photo Credit: Daktronics

Using the SVP platform from Evolve Additive Solutions, Fathom Manufacturing 3D printed the panels directly in ABS, including the clip features. Photo Credit: Daktronics

Fathom instead deployed the SVP platform to 3D print the panels directly with surface finish and properties similar to injection molded ABS. Design for additive manufacturing (DFAM) was accomplished quickly and without the design of experiments (DOEs) that would have been needed to prove out highly automated tooling. The STEP technology contributed to time savings of 63% and reduced the cost by 43%.

“This is a prototyping technology that wants to run production,” Stump says of the Evolve SVP. While the platform is being applied mostly for validation parts and prototypes like the Backbone components right now, it offers a clear pathway into production. The ability to 3D print with the same ABS as injection molding makes it easy to convert a given prototype or bridge production part to molding, if and when demand reaches the tipping point that requires this.

Microfactories “in Region, for Region”

The Fremont facility represents both an advance and a consolidation for Fathom Manufacturing. The site is a downsized operation from the company’s previous manufacturing location in nearby Oakland. But where that former site aimed to offer full-scale production, Fremont is more of a focused additive showroom with production capability for delivering lower volumes of polymer parts quickly. In addition to the Evolve machine, the company also has HP Multi Jet Fusion capacity and multiple Connex and Fortus machines from Stratasys at this location.

In addition to the Evolve SVP machine, the Fremont facility is equipped with these Connex and Fortus printers from Stratasys, as well as HP Multi Jet Fusion machines.

But perhaps more importantly, the Technology Center is also a way for Fathom to maintain a presence in the Bay Area, even as most of its overall additive manufacturing capacity becomes centralized in Wisconsin. The Fremont facility is important as a local point of contact for clients in this region, of which there are many. It is a place where customers can come to see the latest additive technology at work, but also pick up their parts and express their needs in person.

“We want to be in region, for region,” Stump says, and additive is the manufacturing technology that lends itself most readily to being dispersed in this way. Ongoing and conventional production can be tackled at a centralized location, while tech centers can function as local microfactories for product iteration and quick-turn production through AM. As economics and quality of additive parts continue to improve, Fathom Manufacturing’s future could increasingly build on its 3D printing past.

Related Content

A Framework for Qualifying Additively Manufactured Parts

A framework developed by The Barnes Global Advisors illustrates considerations and steps for qualifying additively manufactured parts, using an example familiar to those in AM: the 3D printed bottle opener.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreDecentralized Manufacturing Network Aims to Make 3D Printers a Shared Global Resource

The 3DOS additive manufacturing network will let OEMs and creators take advantage of open 3D printer capacity anywhere in the world.

Read MoreConocoPhillips Sees Oil and Gas Supply Chain Opportunity With Additive Manufacturing

Production of parts when needed and where needed can respond to the oil and gas sector’s multibillion-dollar challenge of holding parts in inventory. The supply chain benefit will justify additive even before the design freedoms are explored.

Read MoreRead Next

Can Additive Manufacturing Compete With Conventional Manufacturing on Cost?

When it can, says Evolve, the design advantages of AM find their way in. The company is beginning to ship its high-speed AM system for polymer part production.

Read MoreHow Bridge Production Is Bringing New Possibilities: AM Radio #14A

Additive manufacturing makes bridge production a more natural factor in the production strategy overall. This has important implications for product development and even what products are possible.

Read More3D Printing as a New Product Launchpad

With 3D printing, Minnesota manufacturer Resolution Medical offers a fast, affordable route for individuals and small to medium-sized businesses to get new medical devices and other products off the ground and into the marketplace.

Read More

.jpg;width=70;height=70;mode=crop)