At the newly opened Collins Aerospace additive manufacturing center in Monroe, North Carolina, the work of material scientist Hyeyun Song, Ph.D., is part of the reason for this facility and why it is valuable to Collins as a whole. The aerospace manufacturing provider has six different strategic business units related to different aircraft systems, such as Advanced Structures, Mission Systems, Power and Controls, among others. The six different units are headquartered in facilities across the country, from California to Connecticut. The North Carolina facility (near Charlotte) is able to serve them all, and in doing so it is developing knowledge from which they all will benefit.

“We are facilitized to expand,” says the site lead for the new Collins Aerospace Monroe facility. Two laser powder bed fusion machines are running in the facility now; a third is on the way. Capacity will be added and the space will be filled as more AM parts move into production.

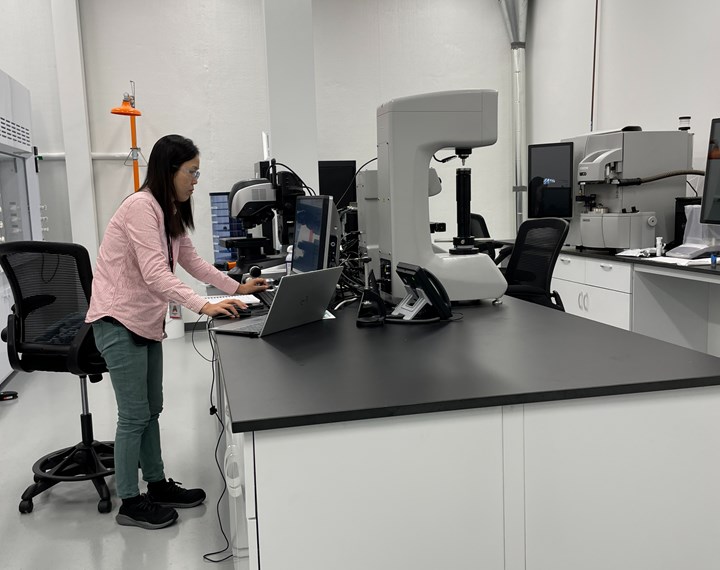

On the day I visited, Dr. Song was evaluating the density of titanium 6Al4V test specimens resulting from various combinations of build parameters. This material and aluminum F357 (AlSi7Mg) are the current focus of the facility. Parts are developed here and mass produced here via laser powder bed fusion in these two metals, and the potential scope of this work across the different business units justifies the company’s investment in both advancing and characterizing this site’s capabilities. Because there are no widely shared quality standards accepted by Collins’ customers for 3D printing with these metals, the company is seeking to create them. By matching process techniques and parameters to measured outcomes, the materials researcher is developing standards internal to Collins that will speed the successful development of AM parts in the future. Meanwhile, she says, “We are developing processes and standards that we will share with customers and regulatory bodies for their acceptance and approval.”

William Haddad oversees this facility as part of his role as Director of Additive Design and Manufacturing for Collins Aerospace. He says the facility’s successes at producing parts through AM, as well as its setbacks along the way, will deliver similar value. That is, taking on a variety of AM components for a range of aerospace applications will teach lessons all the company can benefit from, because those lessons will be learned within a facility all the company’s business units share. Collins’ additive capabilities also include other additive facilities that have existed longer. One in Iowa, for example, serves a specific business unit, Power and Controls, by making parts tailored to this unit’s needs. But with AM in general advancing for all the business units, Collins saw the need for more centralized capacity as well, he says. Meeting the company-wide engineering demands of escalating opportunity in additive will call for company-wide access to learned expertise.

This titanium valve housing achieving considerable part consolidation through internal complexity represents the kind of design engineering investment Collins Aerospace and its customer may want to protect by making the part in house.

“There’s a phrase: ‘mean time to failure.’ In additive, the focus of our efforts is ‘mean time to success,’” he says. For the kinds of complex components this facility sees, process development in AM entails trial-and-error involving process variables such as laser parameters and part orientation, along with choices in the part design that also affect outcome. Centralizing where the company does this trial-and-error and accumulates the resulting learning “is going to give us a faster mean time to success,” Haddad says.

But again, this is just part of the reason for the facility. Another reason relates to the value of the parts made here, and even the value of that learning. The additive manufacturing center will help Collins to control and protect intellectual property.

“As we use additive to achieve complex solutions in assembly consolidation, lightweighting and internal cooling, some of those solutions will represent valuable IP,” Haddad says. The additive processing strategies for parts will sometimes represent IP that is similarly valuable: hard-won knowledge developed through the investment of setbacks and challenges met. Haddad makes clear, “We have suppliers in additive manufacturing, and we will continue to rely on suppliers.” But AM is distinctive for the sophistication of components it makes possible. With AM, the share of production parts containing IP in need of protection is large enough that the way forward with AM for Collins had to involve in-house capability. Advancing with AM therefore meant internal expansion.

“IP” Means Internal Production

The Monroe facility entirely serves internal customers. Engineering teams within the six business units work with the external customers, notably aircraft OEMs, to develop and realize the component and system solutions they need. Those solutions increasingly involve additive parts.

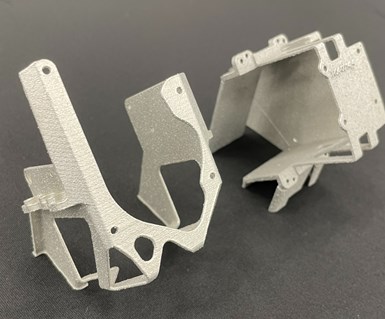

This aluminum bracket is a simpler solution. The original design is seen at right. The reconceived design achieving weight savings through AM is at left. A part like this may have no design secrecy, but the process choices for 3D printing it effectively might represent valuable IP.

Another centralized additive facility with a similar mission within Haddad’s group is in Singapore. This facility is smaller; AM product and process development is performed here, but ultimately it will deliver a smaller number of production parts relative to the Charlotte-area site.

By contrast, the new site was conceived with production in mind. Today it has two laser powder bed fusion machines as its initial capacity, a Renishaw RenAM 500Q (used to run only aluminum) and an SLM 500 from SLM Solutions (used for titanium). Other equipment includes a stress relief furnace, a wire EDM machine for build plate separation from GF Machining Solutions, and multiple Solukon depowdering machines. All that equipment sits in a 14,000-square-foot production area, so there is plenty of room to add more. Taylor DeYoung, site lead for the North Carolina facility, says, “All of the infrastructure such as electrical and gas is already in place, so we are facilitized and ready to expand as the demand continues to grow; we just need the machines.” Another SLM machine is already on the way, to be installed in January.

Not just production capacity will expand at the additive manufacturing center, but also the company’s knowledge of the capability. Dr. Hyeyun Song, material scientist at the Monroe facility, is working to characterize processes and develop AM standards that can also be shared across the company's business units.

That this center will eventually be filled with AM machines and postprocessing equipment is a likelihood not hard to foresee. DeYoung notes, “Each new aircraft platform coming from Airbus and Boeing [Collins customers] has increasingly more AM content.” The opportunities AM affords relate to improved producibility, component weight reduction, sustainment (for parts already in service) and sustainability. Collins Aerospace as a company has so far additively produced more than 75 different parts, including thermal management components, engine components, nacelle components, nozzles, housings and sensors. These parts have shown the company that additive can routinely deliver weight savings of 10 to 30%, while part consolidation via additive and the corresponding manufacturing simplicity can bring part count reductions of 50 to 80% and lead time reductions of 60 to 80%. For the new additive manufacturing center, the first internal customer with parts now in full production here is the company’s Space Systems group, which employs additive not just for weight savings, but also to realize parts with intricate internal channels for temperature control.

And it is this very intricacy that suggests part of the reason for this in-house production facility. “AM introduces new IP challenges,” DeYoung says. The challenge might not be limited to the part, he notes. While visiting, I saw components with intricate internal geometry representative of the kinds of parts with engineering IP built into the design, but I also saw an existing bracket that had been redesigned for additive — a part that offers a chance to replace parts in the field with an equally capable component that is lighter weight and can be made to order quickly. The bracket is straightforward, yet for as basic as the part is, it is possible that something about the build for achieving it — maybe the laser path strategy, maybe the supports or orientation — represents a secret the company wishes to keep.

Still, additive manufacturing demand from Collins Aerospace’s customers is likely to outpace the possibilities of this facility, even when it is full of machines. “We will continue to rely on AM suppliers, and we will even be expanding our supplier relationships,” Haddad says. “But when it comes to our make or buy decisions for additive parts, IP will be the driver.”

Related Content

Two 12-Laser AM Machines at Collins Aerospace: Here Is How They Are Being Used

With this additive manufacturing capacity, one room of the Collins Iowa facility performs the work previously requiring a supply chain. Production yield will nearly double, and lead times will be more than 80% shorter.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreRead Next

Collins Aerospace Chooses PrintSky for Flight Actuation Project

PrintSky will use its expertise to develop flight actuation systems that can resist mechanical loads, dissipate heat emitted by the components, and be tight and insensible to electromagnetic disturbances.

Read MoreTwo 12-Laser AM Machines at Collins Aerospace: Here Is How They Are Being Used

With this additive manufacturing capacity, one room of the Collins Iowa facility performs the work previously requiring a supply chain. Production yield will nearly double, and lead times will be more than 80% shorter.

Read MoreVideo Tour: Collins Aerospace AM Production Site in West Des Moines

The 12-laser powder bed fusion machines are at the heart of the company’s new production capacity for aircraft engine parts in both aluminum and nickel-based alloy.

Read More