The Arrival of the AM Factory: How Proprietary Processes Deliver Production 3D Printing

Various recent articles report on companies using internally developed technology to equip factories and deliver on the promise of AM for production.

Share

Additive manufacturing is bringing about a type of manufacturing business model, and a type of production facility, that is unlike the facilities tailored to any other production process.

And this new type of facility needs a name.

The new business model entails delivering a proprietary additive production process not as seller of the machines to perform that process, but instead as that process’s sole user. In this model, the manufacturer makes machines not to sell, but to equip its own facilities making customer parts.

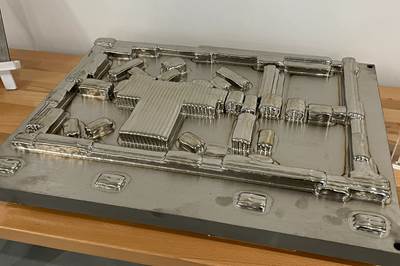

A view inside Norsk Titanium’s additive factory in Plattsburgh, New York.

In recent articles, we have featured companies exemplifying this model. They include Seurat, VulcanForms and Norsk Titanium. These companies have all developed special production-focused AM technologies, and all of them have built — or are building — major plants dedicated to applying the technology and realizing its promise for customers.

There are various reasons why this model makes sense for additive in general, and for these companies’ additive capabilities in particular. By serving as the sole user of a new production technology, these companies have access to all the data on its successes and shortfalls, and can advance the performance of the process much faster. At the same time, 3D printing is an inherently low-labor operation that offers little impediment to a company scaling up capacity as opportunities warrant. Indeed, we see both effects at work in other additive businesses. Manufacturers with proprietary additive processes choose to deliver the process themselves even at smaller scale, and manufacturers using non-proprietary additive production equipment also see advantages in scaling large (such as Zeda). The new type of facility that is by and for proprietary AM processes brings both of these factors together.

But what is the name for this type of facility?

My answer: I land on “AM factory.”

Here is why: It is not a shop; start there. “Shop,” short for workshop, began as a term for the space where manual work is done. In the nineteenth century, an edgy twist was added to the term. The new style of shop in which machines do the work instead of human hands came to be called a machine shop. However, the additive facility is founded on a digital part-making process — it has a different origin.

“Digital foundry” has been offered as a term. (Zeda uses this.) And the term is promising — some additive facilities do provide a digital alternative to casting, which is the work of foundries. However, “foundry” implies metal, and arguably also implies melting. Thus, it is not a broad-enough term to encompass all the additive processes (including polymer as well as solid-state metal) that might scale up in production facilities.

“Additive factory” has a lot to recommend it. The term is simple, which should not be discounted. But more strikingly, this use of “factory” is true to the original word in ways that manufacturing facilities in recent decades have not been. In an earlier generation, the move toward spreading production across supply chains, with many links in the chain, brought more of part production into smaller shops. But now, additive is bringing part production back around into facilities that look more like classical factories. Specifically, the term “factory” suggests a large facility, purpose-built for a particular product or product line, performing many different operations, and employing some processes and tactics that only the factory knows.

The new AM factories satisfy most of this. They are not focused on just one product; they are contract producers — that much is different. Other than that, these new AM facilities tick the boxes “factory” suggests. They include:

- Additive factories favor scale. The team overseeing five AM machines, for example, can oversee 30 without needing anything close to proportional growth in staffing.

- AM factories perform many operations in one place, if only due to the assembly-reducing designs of additive parts consolidating what used to be many different steps into one build.

- Additive factories, as our recent articles emphasize, often employ processes that only the factory knows how to perform.

For companies delivering on the promise of their own proprietary additive processes in this way, scaling up capacity is the way forward. This can happen by filling the current facility, then by establishing other facilities, perhaps in locations close to clusters of customers.

Thus, while the new business model does not involve selling machines, it certainly does involve building them. If it succeeds, then that model leads to the need to equip new, additional facilities like these additive factories we have already begun to see.

[Related: What should we call additive manufacturing businesses? From the AM Radio podcast.]

Related Content

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreRead Next

Seurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read More