PEKK (poly ether ketone ketone) and PEEK (poly ether ether ketone) are both high-performance, semicrystalline polymers that offer good strength, chemical resistance and high use temperatures. Both materials are used for medical implants, among other applications, in part because they offer stiffness comparable to human bone. But the same crystallinity that imparts many desirable qualities to these polymers also makes them challenging to 3D print. We recently featured PEKK suture anchors made through selective laser sintering (SLS) by Oxford Performance Materials, and PEEK cervical spine implants made through fused strand deposition (FSD) by Curiteva on The Cool Parts Show. In this bonus episode, we reconnect with our experts for their perspective on additive manufacturing with these materials. | This bonus episode of The Cool Parts Show is brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- Episode 60: More Affordable Suture Anchors 3D Printed from PEKK

- Episode 63: FDA-Approved Spine Implant Made with PEEK

- Ultem, PEEK or PEKK? Another perspective on choosing between these materials for FFF-style 3D printing

- How a PEKK-based filament with ESD properties was developed for the Orion spacecraft

- Using 3D printed carbon-reinforced PEEK composite and neat PEEK to replace metal parts

- Beyond 3D printing, here’s a breakdown from sister publication CompositesWorld on the future of PEEK and PEKK in thermoplastic aerostructures

Transcript

00:00:00:02 - 00:00:00:11

Pete Zelinski

I’m Pete.

00:00:00:18 - 00:00:01:09

Stephanie Hendrixson

I'm Stephanie.

00:00:01:11 - 00:00:03:22

Pete Zelinski

Welcome to a bonus episode of The Cool Parts Show.

00:00:04:04 - 00:00:13:11

Stephanie Hendrixson

We've had a couple of episodes lately about some high performance polymers, PEKK and PEEK, and we wanted to make this video to just talk about the differences between these two materials and their similarities.

00:00:13:21 - 00:00:37:01

Pete Zelinski

Those episodes are number 60, about 3D printing of poly ether ketone ketone or PEKK and work being done by Oxford Performance Materials. And episode number 63 about a company named Curiteva and the success they're having with 3D printing PEEK poly ether ether ketone. We're going to hear from both of these companies on the differences between those materials.

00:00:37:16 - 00:01:00:06

Stephanie Hendrixson

From kind of a high level of categorization, both of these materials are semi crystalline polymers. So that's in contrast to an amorphous polymer where the molecular chains are sort of randomly dispersed. A semi crystalline polymer as it heats and cools, the molecular chains will form these sort of orderly structures, these crystalline structures. That creates some challenges in 3D printing, which we're going to talk about.

00:01:00:11 - 00:01:15:04

Stephanie Hendrixson

But it also imparts some desirable material characteristics. Both of these materials are part of the poly aryl ether ketone or PAEK family. Materials which are known for their high strength, their chemical resistance, their low flammability and their high use temperatures, among other things.

00:01:15:21 - 00:01:58:20

Pete Zelinski

So the impression I take about these materials is that PEEK wants to solidify by crystallizing, and that crystalline structure gives it very good properties, mechanical properties, thermal properties. But that mechanism of solidification, crystallization comes with some shrinkage, about 2%, and that makes 3D printing challenging. But my sense is PEKK is more of a compromise. It still has very good material properties and a crystalline state, but it also has an amorphous state and in that state it is more malleable and more conducive to success in 3D printing.

00:01:59:10 - 00:02:14:06

Stephanie Hendrixson

Yeah, I think that's true. Both of these are high temperature polymers. You're going to need a hotter than usual 3D printer to work with them probably, but I think it is fair to say that PEKK is going to be it's going to print a little bit more like an amorphous polymer. And so there might be some processing advantages there.

00:02:14:16 - 00:02:40:15

Pete Zelinski

We should say Both of these materials are challenging to 3D print with. Both of them offer excellent properties potentially that make them very useful and very useful to use in additive manufacturing. We have covered two different companies succeeding with these different materials for making medical implants through 3D printing. And we're going to hear from both of them about the differences between these materials.

00:02:41:03 - 00:02:49:00

Stephanie Hendrixson

We'll take these one at a time. So first up, PEKK. Here is Scott DeFelice. He is the founder and CEO of Oxford Performance Materials, or OPM.

00:02:49:18 - 00:03:25:07

Scott DeFelice

PEKK is a high performance thermoplastic. It's a semi crystalline polymer and it's known it's in the field of called poly ketones. And then there's other polymers in that field. But they all have similar characteristics of high temperature tolerance, extreme purity, chemical resistance, biocompatibility, very excellent mechanical properties. So PEKKs a pure thermoplastic. Like all thermoplastic, it can be processed in all the conventional ways. So you can machine it like normal subtractive process.

00:03:25:07 - 00:03:53:21

Scott DeFelice

You can injection mold it, you can extrude it, you can make films, you can make fibers. So we started this 20 years ago thinking, look you can machine great implants out of PEKK and it’s pure. But since then we found out some amazing things. So you know one of them is we can print with it, right? And that has to do with, the very specific chemical nature of this one PEKK polymer that allows you to print with it because it has an affinity to stick to itself.

00:03:53:21 - 00:04:18:13

Scott DeFelice

The main issue when you want to use a high performance thermoplastic in printing, so you have to have a machine that operates at the right temperature range. So there were existing machines that do that. But we also had tools that allow us to sort of modify the melting temperature of our polymers. The printing is done in-house.

00:04:19:07 - 00:04:38:15

Scott DeFelice

We use EOS machines that we've subsequently modified for the purpose of our high temperature process, a powder bed melting process. This is really a pretty advantageous process and that allows you to get fully consolidated, fully dense parts with highly repeatable mechanical performance.

00:04:39:04 - 00:04:57:08

Stephanie Hendrixson

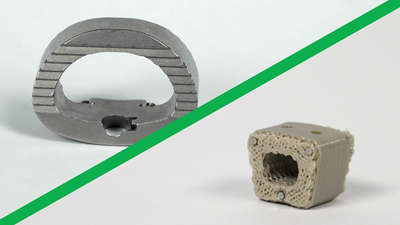

OPM is applying selective laser sintering to make medical implants and other types of parts out of PEKK powder. They are using modified SLS printers to do this, and they're having success with this already. In our full length episode, we talked to them about suture anchors, these little surgical fasteners that they are manufacturing using this method right now.

00:04:57:14 - 00:05:04:16

Pete Zelinski

So let's PEKK and how OPM is succeeding with it. Here is Scott's view on PEKK versus PEEK.

00:05:05:08 - 00:05:31:01

Scott DeFelice

So where they’re the same is they're both very pure materials and they're both biocompatible and they're both mechanically, very much like bone. That's kind of where it ends. The big difference has become in the area of the cell response, and that's really in terms of the antibacterial response and benefits of PEKK and the bone apposition and the bone benefits of PEKK.

00:05:32:00 - 00:05:57:06

Scott DeFelice

Those are sort of at a very basic chemistry level a difference. And then finally, what we have talked about some is the ability to 3D print with PEKK in a powder bed process to make robust mechanical structures. The PEKK definitely differentiates itself there because once you're in that powder bed process, your economics also become very favorable versus PEEK, which can be made in FDM.

00:05:58:11 - 00:06:18:01

Pete Zelinski

Scott sort of ends on that note. That 3D printing of peek is going to have to involve a process like FDM or FFF, and that's a point of agreement. Let's switch gears here and here from Curiteva which is using an extrusion style 3D printing process to work with PEEK.

00:06:18:18 - 00:06:26:00

Stephanie Hendrixson

Here are Todd Reith. vice president of Emergent Technologies and Additive Manufacturing, and Erik Erbe chief science officer at Curiteva

00:06:26:00 - 00:07:02:23

Erik Erbe

Peek is a member of the Poly Arylate family. It has a unique history actually in inner body implants. The very first Interbody implant was the Brantigan cage. It was, I believe, cleared in 1997 or 98, and it was a carbon fiber reinforced PEKK implant and that morphed into the peek implants, which are probably 95 or higher percent of the market in terms of polymers that do not resorb, do not go away.

00:07:03:08 - 00:07:25:22

Todd Reith

The reason why we're using PEEK is because it's a proven material as an implant, and so we didn't want to have to go through the process of revalidating or convincing the FDA that some new polymer is safe within the body. We already had the scientific support of using PEEK.

00:07:26:22 - 00:07:47:09

Pete Zelinski

As Scott hinted earlier, They're essentially limited to an FFF style process. In Curiteva’s case that exact process is called Fused strand deposition. They developed it. We get into how it works in the full length episode. You can catch that, but even that method of FFF printing is challenging.

00:07:47:22 - 00:08:10:21

Erik Erbe

PEEK has a melt temperature around 340-350 degrees centigrade, which is pretty hot. The temperature where it begins to soften is much lower. It's 145. And so you have this range where depending on where you put your nozzle, the diameter of the nozzle, the temperature in the environment in the chamber where you're printing the part, all these things control

00:08:11:02 - 00:08:16:03

Erik Erbe

the semi crystalline to crystalline nature of each layer that you're building.

00:08:16:09 - 00:08:46:14

Todd Reith

And by pulling strands and sort of this idea of the Fused strand deposition, we're actually pulling strands, much like you would do glass where you can create this interesting tension within the layers and that by nature gives us greater material properties in strength and durability that we wouldn't see if we were just doing like a laser sintering process of powder or just depositing small amounts of material.

00:08:46:20 - 00:09:11:02

Stephanie Hendrixson

So these two companies, OPM and Curiteva, are succeeding with these different materials PEKK and PEEK. But they're both making similar things, they’re making medical implants. That's because these materials have some similar properties that make them good for that application. They both have stiffness that's similar to natural human bone. They can both offer good osteo integration and they're both easier to see through on an X-ray than a metal implant would be.

00:09:11:22 - 00:09:27:07

Pete Zelinski

There's a lot more you can do with these materials too. PEEK and PEKK are also being used for aerospace components, for down hole components in the oil and gas industry, for parts in electric vehicles and more.

00:09:27:20 - 00:09:39:09

Stephanie Hendrixson

If you want to hear more from our experts and learn about how they are applying PEKK and PEEK for medical implants, you can check out those full length episodes. We'll link those in the show notes below as well as some additional resources about these materials.

00:09:39:16 - 00:09:40:11

Pete Zelinski

Thank you for watching.

Related Content

3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

Read MoreHow to Organize for Additive Production: AM Radio #42

Tim Simpson and Peter Zelinski discuss the next steps for succeeding with AM: After technical and process successes come the cultural, organizational and even costing considerations associated with this mode of manufacturing.

Read MoreVideo: What Is Electron Beam Melting (EBM)?

Electron beam melting is the higher-energy metal 3D printing process offering advantages when it comes to productivity and thermal stresses. Here is an introduction to EBM.

Read MoreThe New Misperceptions Of AM: AM Radio #35

Tim Simpson and Peter Zelinski discuss a way additive manufacturing has advanced: The misperceptions have shifted. Knowledge of AM among manufacturers is more sophisticated now. The concerns that inform the perceptions of newcomers have therefore changed.

Read MoreRead Next

Ultem, PEEK or PEKK? Choosing Between High-Temperature Plastics

How do you choose between these high-performance materials? A conversation with Arkema and Plural AM sheds light on 3D printing with these polymers.

Read MoreCuriteva on Ti vs PEEK: The Cool Parts Show All Access

Curiteva produces cervical spine implants using PEEK, but today most spine implants are made of metal — specifically, titanium. There are very good reasons to choose titanium, as Erik Erbe describes in this interview clip. But, PEEK may have the edge in terms of stiffness, osseointegration and another important factor we learned about.

Read MoreMore Affordable Suture Anchors 3D Printed from PEKK: The Cool Parts Show #60

Selective laser sintering (SLS) of polyether ketone ketone (PEKK) is being used to produce medical implants that are more cost effective and perform better than their conventional counterparts. We highlight fasteners known as suture anchors in this episode of The Cool Parts Show.

Read More

.jpg;width=70;height=70;mode=crop)