Powder bed fusion is one of the most common 3D printing techniques used for industrial additive manufacturing (AM). PBF is possible with both metals and polymers, although not all materials are compatible.

How Does Powder Bed Fusion Work?

Generally, powder bed fusion works by applying an energy source to fuse together powdered material. A recoater blade or roller spreads a thin layer of powder across a build surface, the energy source selectively melts or sinters the material needed for that layer, and then the build plate descends to make way for the next layer.

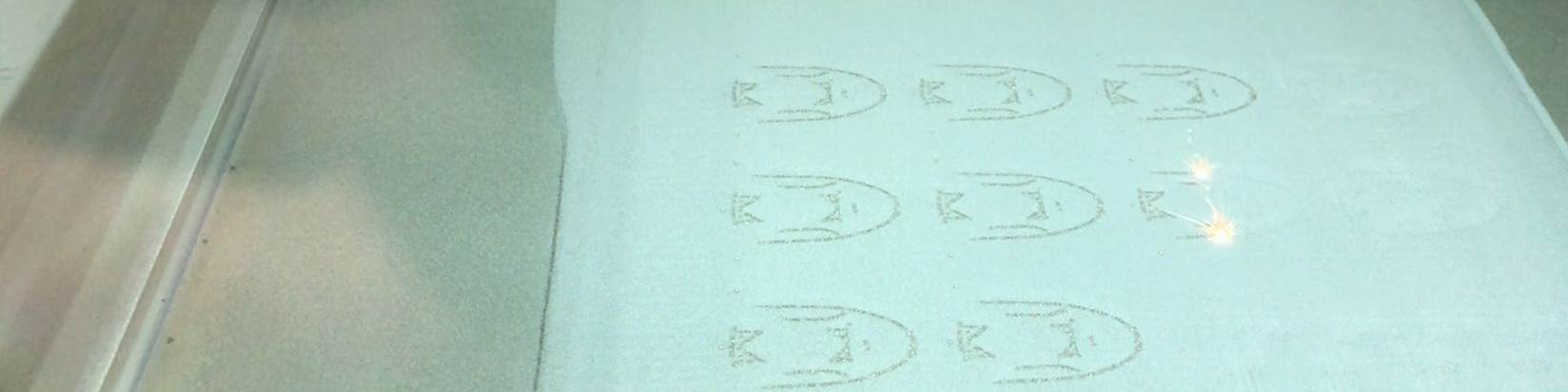

Powder bed fusion builds parts by selectively melting or sintering powdered material. Here, a laser powder bed fusion 3D printer prints in titanium. Created with Giphy

PBF processes depend on a wide range of variables including laser or beam power, spot size, hatch pattern, layer height, powder quality and more.

Historically, process development with these systems has entailed large amounts of trial and error, especially for metals, but new developments in artificial intelligence, machine learning, simulation, sensors and more are helping to make powder bed fusion more predictable and faster to implement.

View suppliers of powder bed fusion equipment

What Are the Different Types of Powder Bed Fusion?

Unsintered polymer powder must be removed from completed SLS parts. In many cases the loose powder can be sieved and reused. Photo: Shapeways

Selective laser sintering (SLS) is a process for 3D printing of polymer powders.

The material is typically thermoplastic, although thermosets are also becoming available for the process.

The powdered material is spread across the bed, then selectively melted using a laser beam. The build plate then drops and the process repeats.

The parts are supported by the surrounding powder during 3D printing and do not require additional support structures. Any unsintered powder can typically be sieved and re-used in the process, sometimes mixed with virgin material.

Laser powder bed fusion (LPBF) is a process similar to SLS but used for metals.

A recoater blade or roller spreads powdered metal across a substrate and a laser beam is used to melt the powder needed for each layer. In contrast to SLS, however, parts begin by being fused to the substrate and often require support structures to stabilize overhangs and help with thermal control. (Through a combination of hardware and software it is possible to reduce or circumvent the need for support structures, however.)

Due to the combustible nature of the metal powders, LPBF is usually performed under inert gas such as argon, or under vacuum. Again, unfused powder can often be reused in the process but may degrade over time due to oxidation.

The rough surface finish left by the powder bed fusion process is sometimes desirable. These hip cups made via EBM will support bone in-growth and healing once in the patient’s body.

Electron beam melting (EBM) is another powder bed fusion process for metals.

An EBM printer functions like a small-scale particle accelerator, firing electrons at the powder bed under vacuum to melt the metal material rather than use a laser.

These electrons can charge the powder bed and cause the particles to disperse, so each layer of material is typically “pre-sintered” before the 3D printing process begins and the entire print bed is kept hot throughout the build.

Parts are 3D printed inside the semi-sintered cake of powder, which provides support during the build and often negates the need for additional support structures. (There is at least one variation on EBM, however, that allows for the parts to be sintered within loose powder).

What Postprocessing Is Required?

Postprocessing varies depending on the material and powder bed fusion process.

In selective laser sintering, the polymer parts are free floating during the build and may only need to be unpacked from the powder bed and cleaned of loose material. Additional finishing operations such as bead blasting, tumbling or dyeing may also be used depending on the application requirements.

Mass finishing can be used to smooth and improve the surface finish of polymer SLS parts such as these custom glasses frames.

In laser powder bed fusion, parts are welded to the build plate and may also include sacrificial support structures.

Finished LPBF builds must be cleared of loose powder, heat treated to relieve stresses, and then cut from the build plate using a wire EDM or a band saw; any supports will need to be cut or broken away as well.

Many LPBF parts will require additional finish machining to add holes, smooth surfaces, etc. Hot isostatic pressing (HIPing), chemical milling, grit blasting, deburring and other steps may also be performed if needed.

Support structures facilitate build orientation, anchoring and thermal transfer for LPBF prints like this custom knife. Typically the entire build plate is heat treated before cutting the part from the substrate, removing the supports, and any additional finishing. Photo: AMRC

In electron beam melting, the metal parts are typically free-floating off the substrate and supported by the semi-sintered powder during the build; they may however have sacrificial supports added to control heat or facilitate postprocessing.

EBM parts will need to be broken out of the powder cake and may require finishing similar to LPBF parts, but do not necessarily require a heat treat step because of the elevated temperatures inside the printer.

Why Use Powder Bed Fusion?

The best applications for powder bed fusion may be instances where 3D printing can:

- support the use of a needed material;

- deliver the product more quickly than a conventionally manufactured version can be made;

- or enable otherwise impossible design freedoms.

Polymer Uses

For polymers, powder bed fusion offers a viable means of:

- mass production as well as a useful method for prototyping and product development;

- bridge production;

- or initial runs of plastic parts intended for injection molding.

Many parts can be made together within the same build, whether they are identical, individually customized or completely different. Minimal postprocessing means that it is possible to print movable joints, “digital foam” and other features that might otherwise need to be assembled.

Selective laser sintering made it possible to build these components and support an innovative new design for a high-fidelity speaker. Photo: 3D Systems

Polymer PBF offers a range of durable materials including nylon, TPU and filled composites. These make it possible to produce automotive and aerospace parts, personal protective equipment, HVAC components, luxury goods, shoe insoles and eyewear among many other applications.

Metal Uses

For metals, LPBF and EBM have proven useful for:

- serial production as well as bespoke or replacement parts;

- conformal cooled molds and other tooling;

- and product development.

In many cases these processes can deliver parts that are as dense as conventional forgings and more dense than castings, and are sometimes used as near-net-shape and fast lead time alternatives to either type of part.

The two metal PBF processes have different strengths, with LPBF generally providing better surface finish and finer detail, while EBM tends to produce a coarser surface finish but can often build thin walls, overhangs or components requiring large meltpools with less warping and thermal stress than laser-based systems.

Laser powder bed fusion has provided production parts for industries ranging from medical to defense, including applications such as spine cages and bone prostheses; headlight heatsinks; fuel nozzles; drone engine components; turbine housing; and brackets of all shapes and sizes.

Medical implants are a common application for metal-based powder bed fusion. This demo LPBF build of spine cage-like parts demonstrates how many of these implants might be printed at once using powder bed fusion.

Meanwhile, electron beam melting has also been successfully applied for medical implants, including custom devices; jet engine turbine blades; brackets for satellites and housing components now on the surface of Mars.

Related Content

What Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read More3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read More6 Trends in Additive Manufacturing Technology at IMTS 2024

3D printers are getting bigger, faster and smarter. But don’t overlook the other equipment that the AM workflow requires, nor the value of finding the right supplier.

Read MoreRead Next

3D Printed Scapula Customized for Patient: The Cool Parts Show #25

A patient treated for a tumor of the shoulder blade was able to preserve full use of the arm thanks to an implant tailored to the precise form of the original scapula and made through electron beam melting.

Read MoreAdditive Manufacturing Is Changing the Rules on Safety

Bringing safety to the forefront helps to mitigate the risk of additive technology within a manufacturing environment.

Read MoreSpeed Is Relative in AM: A Data-Driven Comparison of Multi-Laser Powder Bed Fusion and Binder Jet Processing

There is a difference between the effective print speed and the actual cost to produce the component with AM. John Barnes compares binder jet processing with powder bed fusion for metal parts.

Read More

.jpg;width=70;height=70;mode=crop)