Prototyping

Something More

The integration of manufacturing with product development creates a context that will help additive manufacturing advance.

Read MoreEveryday AM

It’s not just for prototyping. Additive manufacturing can help with the manufacturing side of your business as well.

Read MoreMedical Benefits

Part examples from an established manufacturer of medical implants and instruments illustrate the expanded engineering possibilities that additive manufacturing is making possible.

Read MoreRapid Show Reveals Interest in Additive Manufacturing for Production

Interest in additive manufacturing was evident at last week’s Rapid show in Pittsburgh.

Read MoreAdditive Manufacturing Resource

Often the truism “It’s not what you know, but who you know,” is correct.

Read MoreBaklund: Lessons About Additive

Make extras. Make the part before even winning the job. Additive manufacturing encourages atypical strategies such as these.

Read MoreAdditive Manufacturing in the Job Shop

This small shop invested in production 3D printing in part because its owner expects other manufacturers to make the same move. He wanted a head start.

Read MoreYoungstown Rep. on the Skills Gap and Additive Manufacturing

Rep. Tim Ryan describes the challenge of attracting manufacturing’s next generation, as well as the promise of the technology that this generation is likely to put to use.

Read MoreObjet Improves Rigid Black Material, Adds 16 Composites

Objet Ltd.’s VeroBlackPlus rigid black material is formulated for enhanced dimensional stability and surface smoothness, making it well-suited for fine-detail rapid prototyping. It replaces Objet VeroBlack.

Read MoreBlowing by the Competition with LMD

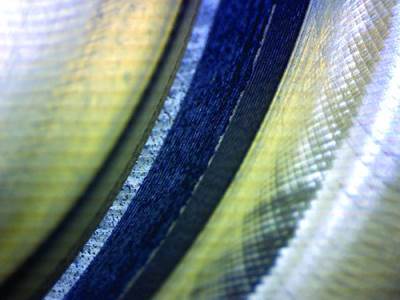

One shop’s evolution from conventional to additive manufacturing involves using laser metal deposition in blow mold manufacture.

Read More