Blowing by the Competition with LMD

One shop’s evolution from conventional to additive manufacturing involves using laser metal deposition in blow mold manufacture.

Today’s blow mold manufacturers are under great pressure to compress pricing and delivery times. They are building molds in half the time and for less than half the price they were 10 years ago. More than ever, they need technology that can help accelerate mold manufacturing and eliminate costly inserts, resulting in lower costs, better functionality and the ability to react to customer requests.

Anthony (Tony) Paget, CEO of blow mold manufacturer Garrtech Inc., is set on demonstrating the value of additive manufacturing (AM) to the moldmaking and molding operations of the company’s blow molding customers. The company is commercializing its patented additive manufacturing blow mold pinch-off process, and test molds have exceeded the company’s expectations in producing HDPE bottles.

Building on a Reputation

Garrtech was founded in 1991 in Stoney Creek, Ontario, by owners steeped in blow molding experience. The company grew by providing various manufacturing services for new blow molds, including part design, mold design and mold construction. Its operations are housed within a 30,000-square-foot facility custom-designed to promote ease of manufacturing and increased productivity.

The company’s initial goal was to be the first blow mold manufacturer in North America to actually build blow molds with a hands-off approach—meaning it was going to cut cavities and complete all of the 2D and 3D machining together. At this time, cavities were being cut by duplicating, casting and hand matching. Garrtech says it was the first to get away from that approach, and this was one of the sources of its success. Paget says the company has always strived to try different things, and that philosophy has served it well.

Today, Garrtech is still looking at what else it can do in mold manufacturing and processing to compress delivery times. Its latest adventure has been with additive manufacturing, and evolution would be the best way to describe the company’s experience.

Paget looked at AM for the first time four years ago. At first, he was not certain how the company could use it. Today, Garrtech is considered a leader in its field at using laser metal deposition (LMD). This AM process replaces toxic materials used for inserts in blow molds, generates cosmetically acceptable surfaces, reduces delivery times, creates more efficient cooling and, over time, will reduce prices.

Bringing in New Technology

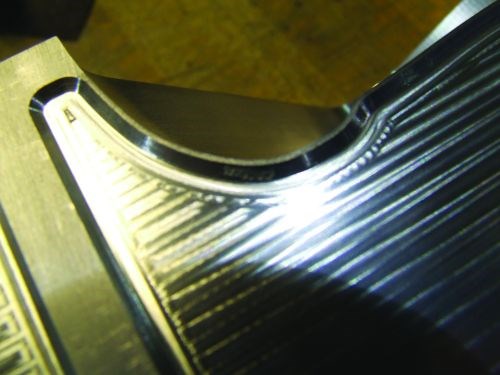

Blow molds are made in sections for ease of manufacture, and pinch-off inserts are added to provide longevity to the mold. (Pinch-offs are used to close the parison along sections of the part line to seal plastic containers.) A typical blow mold has a neck insert, body insert, bottom insert, all necessary pinch inserts and a back plate.

According to Paget, “Garrtech can build a mold with the usual sections and inserts or we can make it solid, using additive manufacturing for the pinch-off. In other words, we do not need pinch-off inserts.”

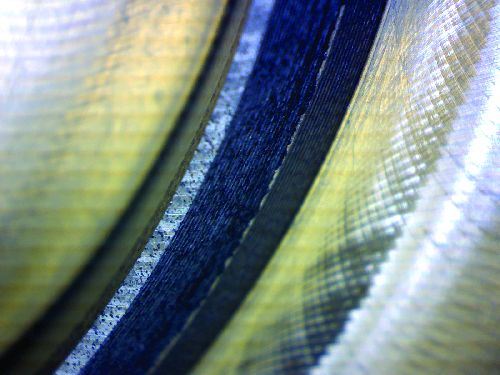

LMD, the method Garrtech uses to make the pinch-offs, differs from other related AM processes in that it works with multiple materials, not a single material. Rather than machining a pocket to accept a wear insert, Garrtech machines a recess to accept LMD material that becomes one with the substrate (the mold), meaning there is no thermal break.

“The bottom line is, with LMD in blow mold manufacture and molding we can replace the standard generic pinch-off inserts, and we can build a mold without any sections at all, providing enhanced benefits to the molder and moldmaker,” Paget says.

He continues, “The very next thing that happens in your design, if you don’t need all of those inserts and you can build a one-piece mold, is you don’t have nearly the amount of design, programming and machining time, and virtually no assembly time. You are not making components or putting components together, so there is less inventory. You are then giving customers what they want in less time and, in the long term, producing a mold that costs less money.”

Right now for blow molding, the LMD application is twofold: it offers 1) the ability to make an integral pinch-off in LMD material with a high wear rate, and 2) the ability to reconfigure and repair.

The LMD process employs unique software and adds material by using high-powered YAG or fiber lasers to fuse fine metal powders, layer by layer, to create fully dense precise parts without the need for thermal treatments. These grown surfaces exhibit near-wrought properties with defined net shape, and they can be tailored to suit most tooling and moldmaking requirements. The LMD process uses exotic, lightweight powder materials, which can be deposited on soft material substrates.

“What we are actually using is what is known in the metals industry as MMCs (metal matrix composites),” Paget says. “That is what we are putting on the aluminum, which is the substrate—the actual blow mold.”

Paget says that LMD applies concentrated, controlled heat to create a mechanical bond. Only enough of the substrate surface is heated to enable the MMC to melt into it to create a mechanical bond.

Normally when welding steel or aluminum, there is substantial heat ingress leading to warping and increased stress. LMD uses only a warm, controlled heat. It does not warp the product or cause undue shrinkage or growth, Paget says.

Understanding the Evolution

Paget had worked with the National Research Council (NRC) of London, Ontario, the Canadian government’s premier R&D organization. The NRC partners with Canadian industry to take research from the lab to the marketplace. This organization was doing laser cladding of like materials successfully, but this was not new technology and it was not the only group doing it.

Paget’s interest was initially piqued by laser polishing. Garrtech wanted to build molds in a more hands-off manner, and many of its molds are highly polished. It was through learning about laser polishing that Paget began to understand that lasers might be viable for other aspects of moldmaking. Frequently a blow molder may need to change a particular cavity or shape due to customer requests, and Paget realized there could be repair and/or reconfiguration applications for laser polishing, despite some apprehension he had about negative effects on the substrate. LMD offered even more potential for these applications.

Demonstrations revealed that LMD not only adhered well to the substrate, it created a denser, harder material. This led Paget to consider one-piece blow molds and the potential for building a mold out of a solid block of aluminum, eliminating the need for inserts, omitting thermal breaks, providing better cooling and eliminating mold sections.

He then realized that, because the laser-cladded aluminum was harder and denser, a highly wear-resistant pinch-off might be possible through this approach. In-house testing proved otherwise. Aluminum oxide was the next possibility tried. This failed due to embrittlement and stress cracks in the pinch-off.

Garrtech then began to experiment with other, proprietary materials—essentially reinforcement materials—to create a hybrid composite.

The solution was metal matrix composites on the aluminum. Paget explains: “With MMCs you have to think about concrete and how it is made of a mixture of 3-2-1—three parts stone, two parts sand, one part cement. You mix them together in a cement mixer, but you also have to add water and air. When all those elements are combined, you have concrete, which has high strength. That is what we are doing. We are putting a form of concrete onto a surface, and that’s the key.”

Garrtech is not putting like metals together but instead is combining dissimilar metals. It uses aluminum in blow molds because this metal is lightweight and easy to handle and machine, and has high thermal conductivity—giving customers the cycle times they want.

“We tried this approach to making molds two years ago in a small production run in an accelerated test with a non-everyday-material,” Paget elaborates. “It performed as well as or better than steel and beryllium copper; however, it did finally crack and break, but only in the corners. So we had to go back to the drawing board to determine if we were encountering a machining problem, a deposition problem or both.”

As Garrtech was getting closer, new issues arose and new materials were introduced. Support equipment and tooling were developed to improve production rate.

The company changed the reinforcement additives and, following very promising success in a laboratory environment, a year ago decided to design and build a mold for a trial production test with a local blow molder. The test was run side-by-side with another mold made in the conventional manner, with a beryllium copper pinch-off.

“That mold has been running for six or seven months now,” Paget says. “To date, the MMC has outperformed the beryllium copper. We moved from the lab (press testing, not running any plastic) to actual molding, and we have yet to see any wear in the MMC. Meanwhile, in the beryllium copper, we see the normal wear.”

Based on that success, Garrtech was able to go to mass production bottle makers and say, “Here is the success we had. Are you willing to try?” It found a customer who was willing to try LMD for high-cavitation, mass-production blow molding.

In this particular case, it was important that the pinch-off withstand the rigors of production. Although the mold using LMD has not run long enough for Garrtech to consider it completely proven, Paget says it has performed admirably—as good as the conventional mold.

Benefiting from LMD

Paget’s ideal LMD process goes something like this: “We put a metal aluminum block on a CNC machine, do all of the machining for a single-piece mold, send the mold via robot into a laser additive manufacturing machine that will laser all the pinch-offs, and then return the mold to the CNC machine and finish-cut the pinches.”

This could be done in a single-piece format or in a regular mold utilizing pinch inserts. Either way, the pinch-offs would be created using LMD, and in the case of the regular mold, pinch inserts would be manufactured in aluminum using LMD, as opposed to in the conventional beryllium copper or steel.

And there are long-term advantages, too. For example, some customers have asked what happens if they damage a mold or if it needs reconfiguration. Currently, customers remove inserts or return the entire mold for repair or reconfiguration via inserting or welding. As an alternative to this, since LMD is an additive process, Garrtech can build up the damaged areas and remachine.

“This is real,” Paget says. “We’ve already done it. We’ve proven that it works in the field. It is a massive change in manufacturing, and we are already headed there. Our problem now is we need a production machine, and today no such machine exists. There are only lab machines whose size, make-up, software and hardware do not meet the rigors of production demands.”

Summary

“It’s been a long time and a great cost to get this far, but the worst is behind us,” Paget says. “We know that, as we move forward, the machinery, materials and applications will get better and better.”

Through its collaborative initiatives, Garrtech will continue to raise the bar in blow mold manufacturing and processing, including demonstrating that molds made from the LMD process can be scanned, machined and inspected to meet operating compliance of container producers throughout the world.

Related Content

Big Metal Additive: The Difference Between a Shape and a Part Is Quality

Preparing to scale directed energy deposition to ongoing full production is not a technological challenge: DED is ready. But it is an organizational challenge, says the company founder. Here is what it means to implement a quality system.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreHow 3D Printing Aids Sustainability for Semiconductor Equipment: The Cool Parts Show Bonus

Hittech worked with its customer to replace fully machined semiconductor trays with trays made via DED by Norsk Titanium. The result is dramatic savings in tool consumption and material waste.

Read MoreNew Equipment, Additive Manufacturing for Casting Replacement and AM's Next Phase at IMTS 2024: AM Radio #54

Additive manufacturing’s presence at IMTS – The International Manufacturing Technology Show revealed trends in technology as well as how 3D printing is being applied today and where it will be tomorrow. Peter Zelinski and I share observations from the show on this episode of AM Radio.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More