Prototyping

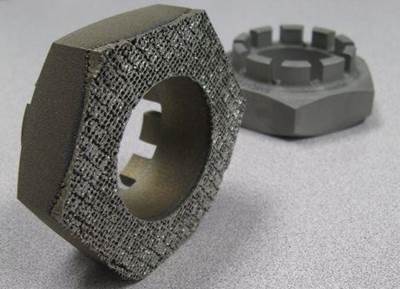

How Do You Make a Howitzer Less Heavy?

Large nuts that used to be solid metal are now grown with a honeycomb structure on the inside for valuable weight savings.

Read MoreCracking the Code to Growth in AM

It takes more than machines on the shop floor to push additive manufacturing to the next level. According to one manufacturer, it takes customer service, education and training, too.

Read MoreLearning Curve

A manufacturer that has succeeded for three generations expects additive manufacturing to be part of the reason why it will succeed in the fourth. One year into its investment in the technology, here is the company’s experience so far.

Read MoreIs AM the New Enabling Technology?

Additive manufacturing can move industrial arts to digital manufacturing and into the hands of the next-generation workforce.

Read MoreRedEye to Join with Other Additive Manufacturing Companies

Stratasys, the supplier of additive manufacturing technology and also owner of additive manufacturing service provider RedEye, announced this week that it intends to acquire two other AM service providers: Solid Concepts and Harvest Technologies.

Read MoreVideo: 3D Printing with Carbon Fiber

Make parts as strong as metal on a desktop machine, the company says.

Watch