Prototyping

Beyond Recruitment: Agile Workforce Planning for Additive Manufacturing

The skills gap is more than a recruitment problem. Long-term agile workforce planning will be the key to filling needs, says Deloitte.

Read MoreCustomizable Bike Frame Developed with Additive Manufacturing

A bike frame featuring metal 3D-printed components demonstrates the potential for mass customization.

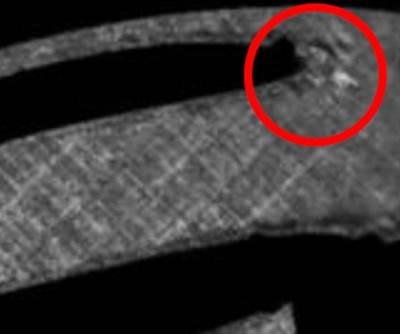

Read MoreInspect the Part As It Grows

The 2016 IAMA was awarded for a technology that monitors thermal radiation to map the internal consistency of a metal part as it is being made. The technology might point the way to an entirely new paradigm for inspection.

Read MoreMake Large Prototypes on a Small 3D Printer

To prove out the designs of brackets that are much larger than its 3D printer, this manufacturer prints the bracket models in pieces and assembles them into prototypes.

Read MoreWebinar to Explore Productivity Gains from Additive and Subtractive Manufacturing

A free webinar presented by Okuma and RPM Innovations on July 20 will address AM’s role alongside subtractive manufacturing.

Read MoreAdditive Manufactured Components Reach Jupiter

The Juno spacecraft includes titanium waveguide brackets made through AM.

Read MoreSLM Achieves Weight Reduction for Robot Actuator

Selective laser melting made it possible to create a lighter, better performing actuator for a quadruped robot.

Read MoreVideo: Metal Additive Manufacturing Without a Laser

Metal 3D printing system applies liquid metal via inkjet nozzles. The technology developer says this process is both fast and precise.

WatchCalling for Backup: Power Protection

An additive manufacturing service provider solved quality issues with an uninterrupted power supply, enabling more reliable production.

Read MoreShould There Be an ISO System for AM? Hear UL’s Recorded Webinar

UL’s Christopher Krampitz discusses adapting quality management systems to fit the needs of additive.

Read More