Make Large Prototypes on a Small 3D Printer

To prove out the designs of brackets that are much larger than its 3D printer, this manufacturer prints the bracket models in pieces and assembles them into prototypes.

It is only a matter of time before we take it for granted that the typical machine shop is equipped with a 3D printer. Or so I argued in a recent commentary that described why a small 3D printer is a natural complement to a CNC machine tool.

Jon Kulikowski, president of Blum-Novotest, responded to that commentary to carry my argument even further. The manufacturer of measurement technology, including laser toolsetting systems for machine tools, routinely uses 3D printing to make prototypes of mounting brackets tailored to particular machine tools before committing expensive production equipment to making this hardware. However, the company president went on to point out that “small” does not have to be limiting when it comes to a 3D printer. Blum-Novotest personnel build prototypes that are much larger than the printer by building them in pieces and bonding the smaller segments together.

Mr. Kulikowski says, “We routinely make prototypes 5 to 10 times the capacity of our 3D printer, a Stratasys Fortus machine with travels of 250 × 250 × 300 mm, by chopping up the model and putting ‘joints’ in it. We then print the parts and glue them together. The result is a prototype that is surprisingly accurate—within 200 microns—and amazingly strong. When we made our first one, I put it through my crude but effective ‘smash’ test, and it passed. Then my engineer who put it together started breathing again.”

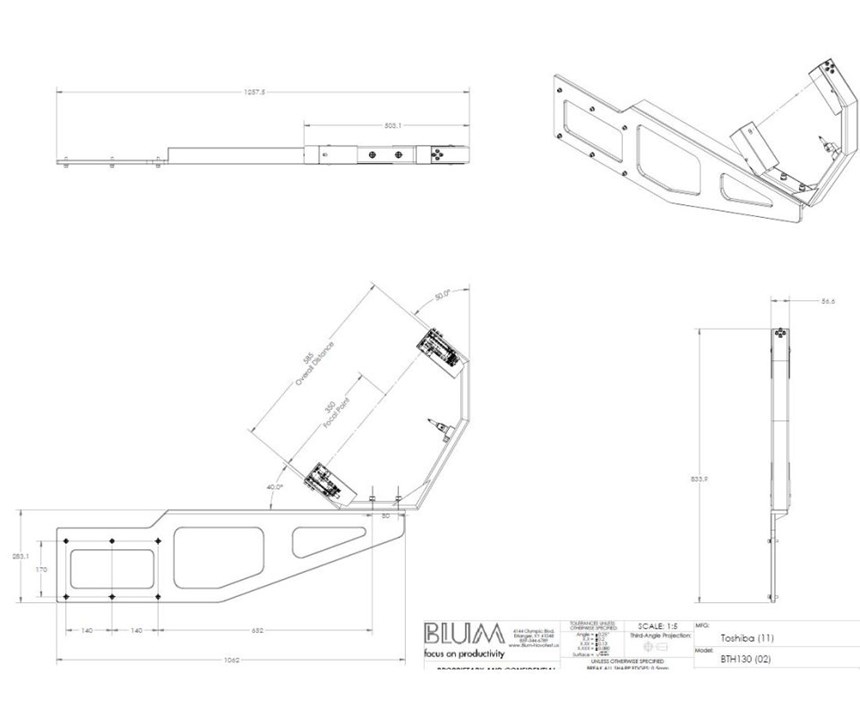

The photo at the top of the page shows an example. Company engineer Brandon Rau holds the prototype for a bracket that will integrate laser toolsetting with a large Toshiba horizontal boring mill. The prototype will allow Blum-Novotest and its customers to be confident in the design and to discover any potential interference points at the machine.

“The prototype has a material cost of about $500. The final bracket priced out at just over $3,200. Obviously, finding mistakes with a $500 mock-up beats making a $3,000-plus bracket two times. It also lets the customer know exactly what they’re getting and how it will affect the machining envelope,” Mr. Kulikowski says.

Meanwhile, there is another benefit beyond the engineering efficiency. “Going to a customer with a 3D print is a marketing tool as well,” he says. “Some are more fascinated with the model than they are with the final product.”

Related Content

-

3D Printed Preforms Improve Strength of Composite Brackets: The Cool Parts Show Bonus

On this episode, we look at a pin bracket for the overhead bin of an airplane made in two composite versions: one with continuous fiber 3D printed reinforcements plus chopped fiber material, and one molded from chopped fiber alone.

-

5 Ways Collaborative Robots and 3D Printing Go Together

Collaborative robots (cobots) are seemingly everywhere — a defining automation technology today. And cobots have a relationship with additive manufacturing that is, well, collaborative. While cobots need custom hardware AM can provide, they are well suited to aid AM production. Here is just some of what we have seen of the interaction between cobots and 3D printing.

-

8 Social Media Posts About Additive Manufacturing: AM Radio #34

Cost savings, modifications, large-format AM and more. In this episode of AM Radio, we discuss what people are saying about additive manufacturing on social media.