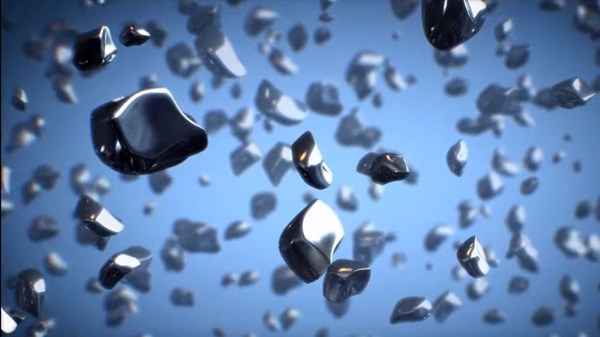

Video: Metal Additive Manufacturing Without a Laser

Metal 3D printing system applies liquid metal via inkjet nozzles. The technology developer says this process is both fast and precise.

Xjet produced this video to describe its new “Nano Particle Jetting” system, which builds solid 3D metal parts without a laser or electron beam. The system instead applies metal in liquid form from standard inkjet nozzles. Indeed, the metal stock used in this process comes packaged in a cartridge that loads into the machine much like a document printer’s ink cartridge. The company says this process builds parts at a rate up to five times that of laser-based additive manufacturing systems, and for fine precision, it is able to build with a layer thickness of under 2 microns.

Related Content

-

3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

-

This Year I Have Seen a Lot of AM for the Military — What Is Going On?

Audience members have similar questions. What is the Department of Defense’s interest in making hardware via 3D printing over conventional methods? Here are three manufacturing concerns that are particular to the military.