Product Development

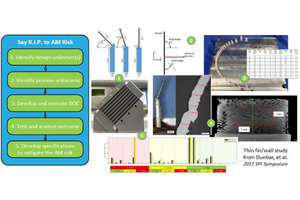

How Thin Can I Make My 3D Printed Part?

Be smart and prototype fast when developing design guidelines for AM.

Read More3D Printed Baseball Mitt Inserts Are Ready for the Big Leagues

Fast Radius was able to use Carbon’s DLS system for both prototyping and production of 3D printed, fatigue-resistant inserts for Rawlings’ REV1X baseball glove.

Read MoreHow Prototyping Addresses Unknowns and Reduces Risks

One benefit of metal AM is the capability to create functional prototypes in less time, enabling you to rapidly iterate on design alternatives during development.

Read MoreAzul 3D’s Lake Printer Enables Mass Manufacturing on Single, Streamlined Platform

Azul 3D can enable manufacturers to transition from prototyping to mass manufacturing on a single, streamlined production platform.

Read MoreThe 12-Month Transformation of a 3D Printed Product's Design

Rapid product development and continuous improvement are among the advantages of utilizing 3D printing for production. Retraction Footwear offers a literal illustration of the design evolution possible in just one year.

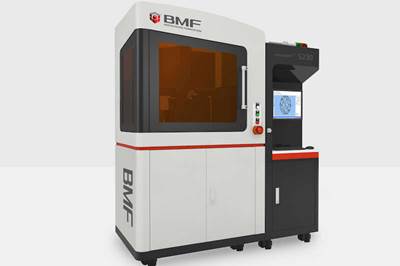

Read MoreBMF MicroArch S230 Offers Design Freedom for Intricate Parts

RAPID 2021: Printer is said to combine ultra-high resolution with unmatched accuracy, precision and speed for prototyping through short-run production.

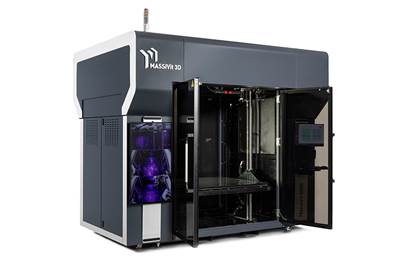

Read MoreMassivit 5000 Expedites Large-Scale 3D Printing

The Massivit 5000 is designed to dramatically expedite large-scale manufacturing, prototyping and tooling for the automotive, marine and rail industries.

Read More3D Printed Tooling Supports Prototype Foam Seating

Automotive manufacturers and other OEMs require mold tooling to build foam components like seat cushions. 3D printed tools could be a faster, more affordable way to prototype and produce these parts.

Read MoreSand 3D Printing Benefits Lightweighting and EV Production

Brooks Crownhill Limited has used Voxeljet’s sand 3D printers to rapidly prototype automobile part molds, with the increased design flexibility enabling lightweighting while strengthening individual components.

Read MoreZortrax Printers Simplify Green Heating System Prototyping

By using Zortrax’s M300 Plus 3D printer to print prototypes in-house, ML Systems saved up to two weeks of lead time and up to 90% of prototype fabrication costs.

Read More