Zortrax Printers Simplify Green Heating System Prototyping

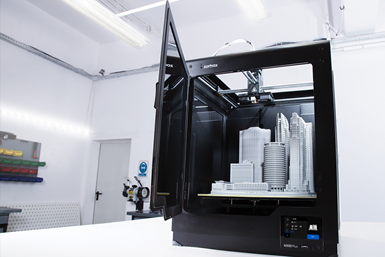

By using Zortrax’s M300 Plus 3D printer to print prototypes in-house, ML Systems saved up to two weeks of lead time and up to 90% of prototype fabrication costs.

The Zortrax M300 Plus 3D Printer can use multiple filaments, enabling engineers to prototype with a variety of materials to discover which works best for their use case. Photo Credit: Zortrax

ML System S.A. has adopted Zortrax’s M300 Plus 3D printer to prototype window frames for glass laminate panes and a free-standing, solar-powered glass heater based on ML System’s HQ Glass technology. The company says these products require a unique design approach that uses the latest manufacturing technologies.

Subtracting Time and Costs Through Additive

“While designing one of our innovative products — a free-standing heater based on the HQ Glass technology — 3D printing was necessary to design a casing that would be both functional and beautiful,” says Paweł Kwaśnicki, a deputy director for research and technology transfer at ML System. “With Zortrax M300 Plus 3D printers, we could print all the necessary parts in-house without outsourcing anything to external subcontractors.”

Doing all the necessary 3D prints in-house optimized ML System’s design process and enabled the company to iterate through multiple subsequent designs just a few hours after having the first version 3D printed — previously, outsourcing had forced the company’s engineers to wait for up to two weeks for each prototype. Zortrax 3D printers have also streamlined the company’s project management and enabled significant prototyping cost optimization. Overall, moving the 3D printing tasks in-house enabled ML System to save up to 90% of its prototype fabrication costs.

ML Systems was able to prototype variations of its HQ Glass-powered free-standing heater mere hours after the first print, instead of needing to wait up to two weeks for each prototype. Photo Credit: ML Systems

The Right Filaments for the Job

For this project, ML System’s engineers worked with a strong, durable ABS filament. Zortrax says this material enabled ML Systems to print prototypes functionally equivalent to end-use products.

The Zortrax M300 Plus 3D printer can use a variety of filaments, and Zortrax’s head of research and development, Michał Siemaszko, speaks highly of the printer’s material diversity, saying, “The capability to use multiple different filaments that invariably comes with using the 3D printing technology allows [operators] to run diverse tests in-house, causing powerful, positive impacts on the quality of the final product.”

Related Content

-

When Advocacy Leads to Adoption: How Pella Applies (and Manages) AM Capacity

The window and door maker offers a picture of successful, widespread 3D printing adoption across the different needs of a manufacturing organization. The outreach and education effort worked. Now, here is the next phase.

-

Complete Speaker Lineup Announced for the 3D Printing Workshop at NPE2024: The Plastics Show

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

-

Sinter-Based Additive Manufacturing Finds a Place Alongside MIM, Press and Sinter at APG

Powder metallurgy company Alpha Precision Group (APG) is applying a particular class of metal 3D printing technology for both rapid iteration in development and flexibility in production.