BMF MicroArch S230 Offers Design Freedom for Intricate Parts

RAPID 2021: Printer is said to combine ultra-high resolution with unmatched accuracy, precision and speed for prototyping through short-run production.

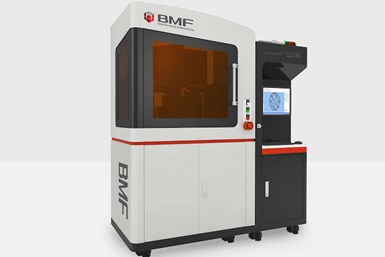

BMF microArch S230

Boston Micro Fabrication’s (BMF) microArch S230 is the latest addition to its roster of industrial-grade, micro-precision 3D printers. This next-generation version of BMF’s highest resolution system is designed for applications that require ultra-high resolution prints (down to 2μm) with accuracy, precision and speed.

The company says the microArch S230 brings unprecedented design freedom and part resolution to researchers and manufacturers needing micro parts with tight tolerances for prototyping through production. The printer is built upon BMF’s Projection Micro Stereolithography (PµSL) technology, a technique that enables rapid photopolymerization of an entire layer of liquid polymer using a flash of UV light at microscale resolution, but with a larger build volume (50 × 50 × 50 mm) and up to 5 times faster prints than previous models in the 2μm series.

Additional key features include active layer leveling, automated laser calibration and the capacity to handle higher molecular weight materials with viscosities of up to 20,000 Cp, resulting in the production of stronger functional parts. The printer is compatible with a growing portfolio of engineering and ceramic resins suitable for end-use parts, including three new materials — AL (Alumina) Ceramic, HT 200 and MT (Magnesium Titanate).

AL (Alumina) Ceramic is a biocompatible and chemical-resistant ceramic resin meant for high-temperature, high-strength and high-stiffness applications such as tooling (injection molding), casing and housings and medical devices. HT 200 is a durable, high-temperature and high-strength resin that can be soldered, and designed for end-use in electrical connectors and electrical components. MT (Magnesium Titanate) Ceramic utilizes a combination of high dielectric constant and low dielectric los, making it suitable for millimeter wave applications such as antennas, wave guides and other electronic components.

The company says that the machine offers quality production of intricate, exact and replicable parts, making PµSL optimal for end-use and prototyping use cases across industries that were once left out of the AM landscape, including medical device manufacturing, microfluidics, MEMS, biotech and pharmaceuticals, electronics and electrical connectors, and research and development.

Related Content

-

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

-

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

-

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.