Postprocessing

AM Companies Collaborate With Wilson to Create First Airless Prototype Basketball

General Lattice’s enterprise solutions team worked with Wilson to bring its concept to life by streamlining the design and iteration process through the use of its computational design tools and workflows.

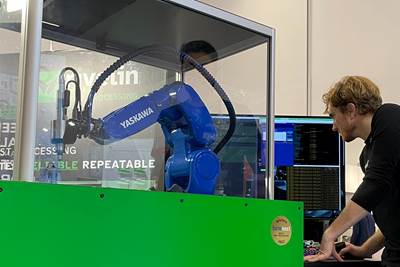

Read MoreThe Robot Craftsman: Force Sensing and Vision Help Realize Automated AM Postprocessing (Includes Video)

Automated production via additive manufacturing will need automated postprocessing. This UK startup is equipping robots with the capabilities needed for critical, fine-detail finishing of metal 3D printed parts.

WatchFraunhofer ILT, 6K Additive Partner on AM Life Cycle Assessment

The study conducted at the labs of Fraunhofer ILT analyzes an additively manufactured industrial component that includes the environmental impact from powder, printing and postprocessing.

Read MoreSolukon Expands Compatibility of Unpacking, Cleaning Station for Plastic Parts

With adapters for EOS P 1 and P 5 series SLS manufacturing systems, the Solukon SFP770 postprocessing system can now accommodate build boxes from other leading printers, enabling Solukon to tap new markets in the area of polymer postprocessing.

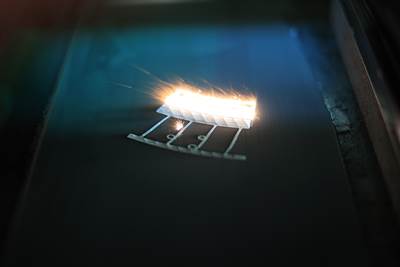

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

WatchAalberts Surface Technologies Forms U.S. Heat Treatment Business Unit

Combining 17 diverse facilities into Aalberts Surface Technologies - HIP|Braze|Heat Treatment makes it one of the largest providers of thermal processing and metal joining technologies in the U.S.

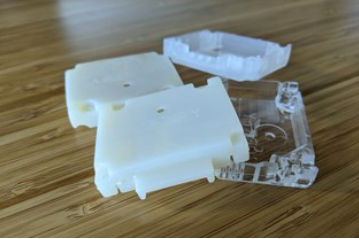

Read More3D Printed Mold Tooling Advances in Performance With Proprietary Resin

Material improvements offer turnkey production and cost trimming with 3D printed mold tooling. A new, proprietary resin addresses the current limitations associated with 3D printing in polymer.

Read MoreAM Schedule Optimizer Enables Cost Optimization for Production Processes

Gravity Pull System’s Schedule Optimizer and Management software optimizes the additive manufacturing production process for cost and maximum machine utilization.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

WatchAM Sister Brand Modern Machine Shop Promotes Brent Donaldson to Editor-In-Chief

Experienced writer and editor takes the reins for media brand which has reported on the CNC machining and technology industry for nearly 100 years.

Read More