Fraunhofer ILT, 6K Additive Partner on AM Life Cycle Assessment

The study conducted at the labs of Fraunhofer ILT analyzes an additively manufactured industrial component that includes the environmental impact from powder, printing and postprocessing.

Share

Read Next

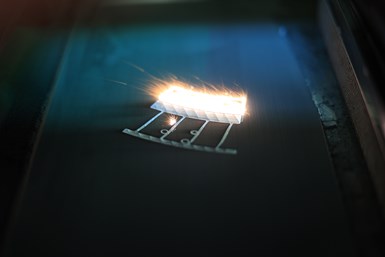

The assessment found that for Ni718 powder, 6K’s UniMelt process delivered at a minimum a 91% energy reduction and 92% carbon emission reduction from traditional processes. Photo Credit: 6K Additive

6K Additive, a division of 6K, and the Fraunhofer Institute for Laser Technology (ILT), are collaborating to create a complete life cycle assessment (LCA) for additive manufacturing (AM). The study will use sustainably manufactured Ni718 powder, produced by 6K Additive, for an industrial component manufactured on a laser powder bed fusion (LPBF) machine to better understand the carbon footprint from material through AM process and postprocessing.

“There are conflicting views on additive manufacturing regarding its environmental impact compared to traditional manufacturing,” says Dr. Jasmin Saewe, Fraunhofer ILT’s head of department for laser powder bed fusion. “The goal for this study is to analyze factual data to help us understand the real environmental impact for printing a metal AM part using LPBF. We also thought it was extremely important to evaluate the entire process, including powder manufacturing, which is why we partnered with 6K Additive, who has a proven method of sustainable powder manufacturing.”

It is said 6K’s UniMelt platform offers multifaceted sustainability benefits. 6K Additive previously released two life cycle assessment projects for both titanium and nickel powders. This study was conducted by Foresight Management, an independent company that quantified the environmental impact associated with the production of printable metal powders and specifically compared atomization technology methods to 6K Additive’s. It was found that for Ni718 powder, 6K’s UniMelt process, at minimum, delivered a 91% energy reduction and 92% carbon emission reduction from traditional processes. The independent study can be downloaded.

“We are excited to partner with Jasmin and her team at Fraunhofer ILT for this research,” says Frank Roberts, 6K Additive president. “Our previous study clearly highlighted the environmental advantages our UniMelt technology has over atomization, but this collaboration takes it to the next step shedding light on the entire AM process. The market has embraced sustainability and the results of this study will provide the tools to allow customers to identify real solutions and help organizations drive toward carbon neutrality.”

6K Additive says it is the world’s first producer of AM powder made from sustainable sources and offers a full suite of premium powders, including nickel, titanium, copper and refractory metals such as tungsten and rhenium. The UniMelt system is a microwave production-scale plasma system, with a uniform and precise plasma zone with zero contamination and high throughput production capabilities.

- Learn about 6K Additive’s Environmental Sustainability Research Award from the Additive Manufacturing Green Trade Association (AMGTA) for its work on the UniMelt powder manufacturing process.

- Read about the 6K Additive partnership with Incodema3D in which 6K says its nickel alloy 625 powder surpassed every quality measure for powder supply and recycling in tests performed by Incodema3D.

- Take a look at this article which details the results of an independent analysis that shows 6K Additive’s UniMelt process uses 91% less energy with a 92% reduction in carbon emissions over traditional methods for nickel production.

Related Content

How Electroplating Works for Polymer 3D Printed Parts

Baltimore-based RePliForm specializes in electroplating of 3D printed polymer parts for functional applications. This video explores how the process works, and potential benefits and uses for this technique.

Read More3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More