Postprocessing

Dyndrite, UPM Work to Bring Data Intelligence to Metal 3D Printing Build Plates

The collaboration aims to reduce print failures and enable reliable supply chain for additive manufacturing production.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

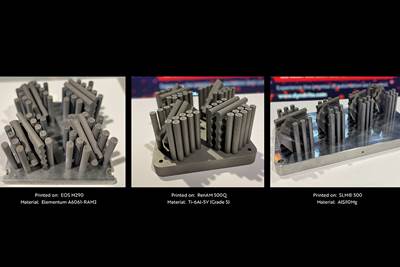

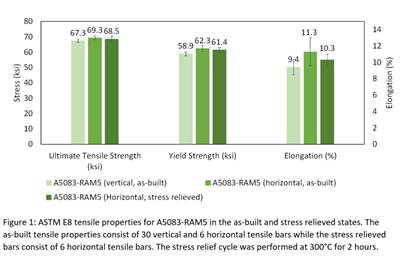

Read MoreElementum 3D’s High-Strength Aluminum Alloy Eliminates Need for Heat Treatment

Elementum 3D’s A5083-RAM5 aluminum alloy enables manufacturers to print advanced components from a high-strength aluminum alloy with reduced postprocessing time and cost.

Read MoreSigma Additive Solutions Partners with DyeMansion for Postprocessing

The collaboration adds an integrated hardware/software solution option that offers extra quality assurance for DyeMansion’s postprocessing solutions — the DM60, Powershot Performance and Powerfuse S.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreUnited Performance Metals Is the One-Stop Build Plate Shop for Production AM

United Performance Metals (UPM) started producing build plates for metal 3D printing in 2019. Now, the company offers full refurbishment and inventory management for this critical additive supply — with more to come.

Read MoreAmerica Makes Announces Project Call for Process Qualification/Requalification Totaling $3.2M

Proposal submissions for the Demonstration of Novel Methods for Effective AM Process Qualification/Requalification – Delta Qualification project call are due by May 22.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreAvia Tools' Depowdering Systems for Metal 3D Printed Parts

Aviation manufacturer only landed in the additive manufacturing segment out of necessity in order to address a client’s depowdering issue. Now it has developed a range of system sizes for any 3D printed part up to 1 metric ton and 1.5 m tall.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Watch