Postprocessing

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

WatchDyeMansion Delivers 1,000th Machine to Zeiss Vision Care

The machine will be used at Zeiss Vision Care’s Aalen, Germany, site to additively develop and manufacture tools and components for the production of individual precision eyeglass lenses.

Read MoreWhat We Found at Formnext 2023

New metal processes, new possibilities for existing processes, the next step for copper and more. Here is a summary drawing on all our reporting from November’s event.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

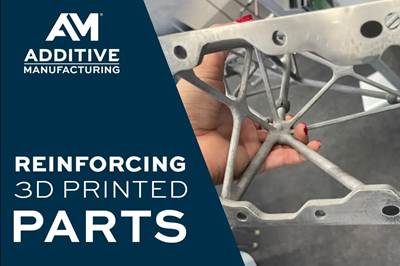

Read MoreVideo: Reinforcing (and Joining) Parts After 3D Printing

Reinforce 3D has developed a method that can be applied to strengthen 3D printed parts by feeding continuous fiber and resin through them. The technique also enables joining parts of various materials and manufacturing methods.

WatchProtolabs Opens New DMLS Facility to Meet Increasing Additive Demand

Protolabs recently opened the doors to its new DMLS additive manufacturing facility to support its customers’ growing demand for AM. The facility, built from the ground up, was designed to accommodate a smooth and safe workflow, continue expanding machine and technology offerings and promote burgeoning additive production.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Listen8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

WatchWhen Additive and Conventional Processes Work Together, the Result Is Manufacturing

Various recent articles demonstrate 3D printing and established processes finding one another and working together.

Read MoreFormlabs Augments Fuse Ecosystem With Fuse Blast, Automated SLS Postprocessing

Formnext 2023: Media blasting, once a recommended step, is now a needed requirement and the Fuse Blast eliminates struggles experienced in manual postprocessing efforts.

Read More