Solukon Expands Compatibility of Unpacking, Cleaning Station for Plastic Parts

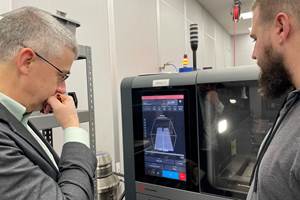

With adapters for EOS P 1 and P 5 series SLS manufacturing systems, the Solukon SFP770 postprocessing system can now accommodate build boxes from other leading printers, enabling Solukon to tap new markets in the area of polymer postprocessing.

Solukon has opened up new options for the postprocessing of plastic parts by adding adapters to its SFP770 unpacking and cleaning station, expanding the system’s compatibility which can now also accommodate and clean parts manufactured with EOS P 1 or P 5 systems.

“We’ve received several requests for a postprocessing system, especially for the EOS P 500,” says Andreas Hartmann, Solukon CEO and CTO. “Since the EOS P 500 is a standard plastic printer, our SFP770 postprocessing system paired with the correct adapter is now available to a much larger user base.”

Solukon introduced the SFP770 in fall 2020, presenting it as a postprocessing system for plastic parts manufactured by an EOS P 7 series printer. The system was developed after an automotive industry customer approached Solukon with a request to be able to both unpack and clean polymer components automatically, without the user coming into contact with the plastic powder. With consideration for every requirement — such as compact design and maximum flexibility — Hartmann developed what he says is the perfect system in just a few months, the SFP770.

The company says the SFP770 is a one-of-a-kind postprocessing system as it is the only one to include both an automated unpacking station and a cleaning station for SLS components in just one system. The station is compatible with EOS P 7 series systems and encompasses the 3D printer’s entire build box. With the new adapters, the SFP770 can also integrate build boxes from EOS P 1 and P 5 printers.

Automation of both the unpacking process and the transfer to the cleaning process means that the operator has almost no contact with the powder. This combination of unpacking and cleaning in one system makes “dust-free AM production” possible. The company says the automation and combination of two high-cost secondary processing steps also increases the acceptance and feasibility of industrial AM production.

The flexible programming of the postprocessing system is another great advantage. “Because so many process parameters can be programmed, the SFP770 achieves the best cleaning results, independent of build material and without manual intermediate steps,” Hartmann adds. “Our system offers another advantage — parts of varying shapes and sizes can be cleaned simultaneously, which increases the flexibility and productivity AM production.”

In addition to the cleaning process itself, Solukon’s SFP770 also optimizes the preparation of the blast material (for example, glass beads). While standard systems typically separate glass beads from plastic powder using air separators or cyclones, Solukon uses ultrasonic sieves. This is said to produce very clean glass beads, resulting in almost no losses.

Solukon sees itself well prepared for future integration of the SFP770 in fully automated manufacturing systems. “We expect plastics manufacturing to trend strongly toward a focus on postprocessing because it constitutes the decisive step in determining if something is truly manufactured in series or not,” Hartmann says. “You can optimize a manufacturing process for serial production as much as you want, but if the subsequent postprocessing fails to meet the same high standards, you will not have true serial production. At Solukon, we therefore expect to see an increased demand for automated unpacking and cleaning stations.”

- Listen to this episode of AM Radio #28 in which the AM team discusses postprocessing solutions. Follow a inserted link to watch Stephanie’s video made on the floor at Solukon’s Formnext 2021 booth.

- Read about Solukon’s SPR-Pathfinder Software for Automatic Depowdering, which is designed to calculate the ideal motion sequence for the most complex geometries, finding the best path to enable the powder to flow out completely.

- Watch the video and read the article about “Why AM Leads To Internal Production For Collins Aerospace” — using systems that include multiple Solukon depowdering machines.

Related Content

Top 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreFreeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read More3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More