Polymer

Formlabs’ Elastomeric Resins Expand Options for Patient-Specific Care

Formlabs’ first elastomeric BioMed materials — BioMed Elastic 50A Resin, BioMed Flex 80A Resin and IBT Flex Resin — can streamline workflows and reduce labor time for flexible, dental and medical biocompatible parts.

Read MorePostPro SFX Desktop Vapor Smoothings Enhances Parts’ Visual, Functional Properties

Formnext 2023: This desktop chemical vapor smoothing machine features a compact benchtop design, making it well suited for R&D and low-volume prototyping projects.

Read MoreChromaMotive D65 Parts Perform Well in Range of Extreme Temperatures

Formnext 2023: The Shore D thermoset polyurethane is well suited for applications that have varying temperature requirements, in a range extreme cold to elevated temperatures from -30 up to 120°C.

Read MoreEvonik’s Infinam TPA Is Elastomer Powder Material for SLS 3D Printing

Formnext 2023: Infinam TPA 4006 P is optimized for SLS technologies, opening up new consumer goods applications.

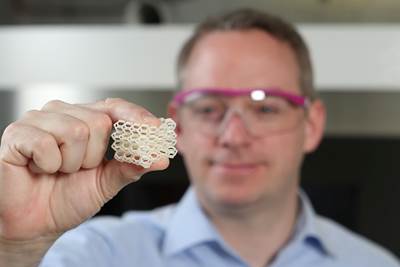

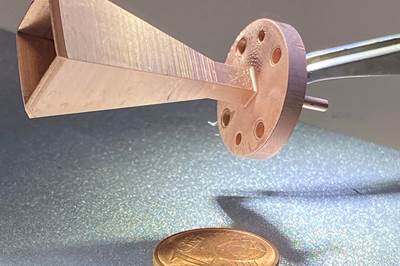

Read MoreHorizon Microtechnologies’ Functional Coatings for Conductive, Durable Parts

Formnext 2023: Horizon Microtechnologies offers functional coatings on 3D printed parts with micrometer-scale precision, enabling the micro-additive manufacturing of conductive and durable parts.

Read MoreHP Works With Brooks Running to 3D Print Performance Footwear

HP has collaborated with Brooks Running to create the Brooks Exhilarate-BL which features 3DNA, a 3D-printed midsole technology that delivers a propulsive, bouncy ride.

Read MoreCompact TiQ Series Offers Versatile 3D Printing for Fiber-Reinforced Filaments

Formnext 2023: The TiQ 2 is particularly economical and well suited as an entry-level additive manufacturing solution because of its open material system.

Read MoreAM Solutions Offers Postprocessing Systems for Higher Productivity, Cost Efficiency

Formnext 2023: AM Solutions has developed a range of postprocessing systems for additive manufacturing (AM) to enable a higher degree of automation and streamlining for the entire AM process chain.

Read MoreBOFA Offers Compact Printing Filtration, Atmosphere Management

Formnext 2023: BOFA’s 3D PrintPRO 4 unit is part of the 3D PrintPRO lineup, offering a filter exchange design and the company’s Intelligent Operating System (iQ).

Read MoreAdditive Manufacturing's Evolving Role at Fathom Now Emphasizing Bridge Production

Bridge production is currently the biggest opportunity for additive manufacturing, says Fathom Manufacturing co-founder Rich Stump. How this service provider leverages AM while finding balance with other production capabilities.

Read More