HP Works With Brooks Running to 3D Print Performance Footwear

HP has collaborated with Brooks Running to create the Brooks Exhilarate-BL which features 3DNA, a 3D-printed midsole technology that delivers a propulsive, bouncy ride.

Share

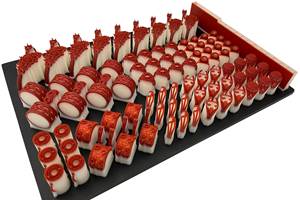

Brooks will release a limited number of Exhilarate-BL pairs as part of a test-and-learn program to select Brooks Wear Testers and Brooks Run Club loyalty members. Photo Credit: HP

HP is collaborating with Brooks Running on the creation of the Brooks Exhilarate-BlueLine running shoe. The partners say that the footwear developed by the Brooks BlueLine Lab is harnessing technology, biomechanical research, engineering and design to advance the power of running shoes. The Lab’s newest innovation, the Exhilarate-BL shoe is designed, engineered and manufactured in partnership with HP using its 3D printing solution.

The Brooks Exhilarate-BL features 3DNA, a 3D printed midsole technology that delivers a propulsive, bouncy ride. It has also been specifically designed and tuned to groups of sizes based on runner data so that each runner has the optimal cushioning and spring with each stride. HP says it has independently validated that its Multi Jet Fusion 3D printing technology produces midsoles that deliver higher energy return than 90% of the midsoles in running shoes on the market today.

Brooks will release a limited number of Exhilarate-BL pairs as part of a test-and-learn program to select Brooks Wear Testers and Brooks Run Club loyalty members who have synced their wearable devices through Brooks’ platform in partnership with DashLX. Through wearables, Brooks is able to access runner data — including their stride lengths, cadences and other factors influenced by height and weight — that will help inform future iterations of Brooks shoes featuring 3DNA.

“Using HP’s 3D printing technology has allowed our design team to fine-tune elements of the midsole right down to the millimeter in ways that wouldn’t have otherwise been possible,” says Nikhil Jain, director of footwear product line management and BlueLine at Brooks. “As a brand rooted in the science that every individual has a unique motion path, we’re just scratching the surface in terms of how we can change the underfoot experience and use 3D printing to deliver a premium-performance run experience with the potential for greater optimization.”

At the same time, Brooks has been able to do so more sustainably by using less materials during production. “As a brand, we are focused on doing our part to ensure the shoes that we are building take a lot less energy and virgin material to manufacture,” Jain adds. “And, from a sustainability perspective, we are learning how 3D printing can help us on that journey.”

- Learn about another sneaker concept. It features a one-piece 3D printed TPU construction that was engineered with the HP 3D printing team based in Barcelona and manufactured using the latter’s Multi Jet Fusion technology.

- Here’s a story about custom heels that bring sustainability, circularity, material frugality and more to fashion footwear — while also providing a comfortable, custom-made shoe. The recyclable, 3D printed shoe platforms are made via Multi Jet Fusion (MJF), the powder-based process from HP, at a partner facility.

Related Content

3D Printed Ductile Spikes for Better Sound Quality: The Cool Parts Show Bonus

Work on 3D printing flexible metal bellows has led to other applications, including the development of ductile spikes that sit between a speaker and the surface below to help limit vibration and isolate the audio equipment.

Read More3DEO Wins Design Excellence Awards

3DEO was recognized for outstanding applications of powder metallurgy.

Read More3D Systems Offers MJP 300W Printer, Wax Material for Advanced Jewelry Additive Manufacturing

The combination of the MJP 300W jewelry printer and VisiJet Wax Jewel Ruby enables jewelry designers to more efficiently achieve new designs with greater design freedom and improved surface finish.

Read MoreItalian Furniture Maker Uses WASP Technology to Create 3D Printed Pendant Lamps

The versatility of 3D printed ceramic enabled the designers to shape a weave reminiscent of the beehive concept, enhanced by the light source.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More