Compact TiQ Series Offers Versatile 3D Printing for Fiber-Reinforced Filaments

Formnext 2023: The TiQ 2 is particularly economical and well suited as an entry-level additive manufacturing solution because of its open material system.

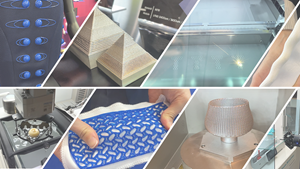

The TiQ and LiQ series 3D printers from InnovatiQ are well suited for processing fiber-reinforced filaments and standard silicones. Photo Credit: innovatiQ

Arburg Additive and innovatiQ (an Arburg brand) offer a range of products for industrial additive manufacturing (AM) based on granulates, filaments and liquid silicone (LSR). The TiQ and LiQ series of 3D printers from innovatiQ can process fiber-reinforced filaments and certified LSR.

The TiQ series of printers are well suited for fiber-reinforced filaments. The compact 3D printers in the TiQ series have a CNC control system for processing filaments using the fused filament fabrication (FFF) process. The company says the TiQ 2 is economical and well suited as a versatile, entry-level AM solution because of its open material system. It features loadable suction pads and mechanical grippers made of fiber-reinforced PA and PP with individualized fingers that are mounted on robot arms and used for picking up components.

The TiQ 5 Pro has integrated material drying and an active build chamber temperature control. Featuring a build chamber of 500 × 400 × 450 mm, it is a 3D manufacturing machine for large components in an extra large format. Its versatility includes handling hard or soft material as well as high-performance polymers requiring a heated build chamber and filaments that require process drying. It is also suitable for the economical printing of large components made of fiber-reinforced or high-temperature materials.

The printer has an actively heated process chamber that can be operated at temperatures of up to 155°C. This enables particularly demanding materials to be processed in the 500 × 400 × 450 mm dimension. The integrated material drying unit keeps hydrophobic filament in the necessary drying state. Material drying increases process reliability and supports the surface quality of the printed components.

All 3D printers from innovatiQ are operated using the intuitive industrial controller GestiQ-Pro. The optional SmartMonitoring system enables several printers to be monitored simultaneously during production. Liquid additive manufacturing (LAM) technology can be used to print items such as bellows, soft grippers and end-of-arm tooling (EoAT) for automation, as well as industrial seals and nozzle closures in various Shore hardnesses — all with high process reliability.

- Read about the opening of Arburg’s Faberlab Additive Center in Italy. The goal for the center is to demonstrate the potential of industrial additive manufacturing to prospective and existing customers of 3D printing technology on real machines.

- Learn more about Arburg technology with its Freeformer 750-3X 3D which features a larger build chamber, providing more space inside the build chamber for larger components.

Related Content

Trinkle Additive App Suite Features Collection of Accessible, Intuitive Design Apps

Formnext 2024: The Additive App Suite builds on the success of the company’s fixturemate — a user-friendly design app for creating fixtures. The software includes three new apps with more to come.

Read MoreAssonic Develops Automated System for Processing Reactive Metal Powders Without Gas Loss

Formnext 2024: The Assonic SPC 500 system features a closed circuit for conveying both powder and gas to eliminate gas loss while processing reactive metal powders in additive manufacturing.

Read More8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read More10 Video Reports From Formnext 2023

Our Formnext video playlist: Stephanie Hendrixson and Peter Zelinski report on various technologies seen at Formnext 2023 in brief videos they filmed at the show.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More