BOFA Offers Compact Printing Filtration, Atmosphere Management

Formnext 2023: BOFA’s 3D PrintPRO 4 unit is part of the 3D PrintPRO lineup, offering a filter exchange design and the company’s Intelligent Operating System (iQ).

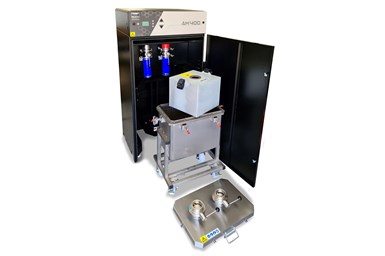

The 3D PrintPRO 4 is designed for large-format capability for fused filament fabrication, stereolithography, digital light processing and material jetting processes. Photo Credit: BOFA

BOFA offers a range of 3D printing filtration and atmosphere management technology for additive manufacturing (AM), including the enhanced-capacity 3D PrintPro 4 unit, which is part of the 3D PrintPro lineup. The unit features a filter exchange design and the company’s Intelligent Operating System (iQ).

The 3D PrintPro 4 is designed for large-format capability for fused filament fabrication, stereolithography, digital light processing and material jetting processes, delivering advanced, high-capacity filtration and optimal temperature control and airflow management.

The lineup also includes the 3D PrintPro 2, which filters emissions generated by small-format, open-framed or partially enclosed fused deposition modeling/stereolithography 3D printers. Another system is the 3D PrintPro 3, which is suited to medium-sized fused filament fabrication and small, enclosed stereolithography, multijet printers. The AM 400 printer uses technology to enable the safe on-site exchange of the filters that help remove potentially harmful particulate from metal AM processes.

“BOFA has continued to develop and enhance its range of additive manufacturing filtration and atmosphere management technology,” says Haydn Knight, BOFA sales and marketing director. “Through our innovations in the filtration of emissions and airflow control of high temperature processes, manufacturers can reap the rewards of productivity gains and safeguard product quality at the same time.”

- Learn more about BOFA technology as it enables users to 3D print their own fume extraction system connectors. The company decided to make the ‘print your own connectors’ available in response to customer requests to improve ease of connectivity with BOFA’s extraction systems.

- Read about BOFA’s 3D printing filtration and atmosphere management technology. BOFA’s latest innovations focus on the filtration of emissions and the control of high-temperature processes through airflow management to optimize product quality and productivity in a 3D printing environment.

Related Content

-

Finland’s Largest Metal 3D Print Withstands Pressure Vessel Test, Vastly Exceeding Expectations

The pressure vessel was created in cooperation between Andritz Savonlinna Works and the Finish Additive Manufacturing Ecosystem (FAME), and withstood the nondestructive and destructive tests carried out by LUT University.

-

The AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

-

Semiconductors, Tungsten, AM Affordability and More from Formnext 2024: AM Radio #56

The trade show included increased applications for the semiconductor market, machine launches and technology advances aimed at cost cutting, plenty of LFAM and more. Listen to our conversation on Formnext 2024.