Tool Steel Alloy Combines 3D Printability with Hardness, Ductility for Tool and Die

Formetrix’s L-40 for powder bed fusion 3D printing enables complex mold geometries at efficient print speeds, with low risk of cracking.

“Printing conventional tool steels with powder bed fusion (PBF) just really doesn’t work economically,” says Jonathan Trenkle, vice president of research, development and operations at Formetrix. “We wanted to design an alloy that could easily be printed by powder bed fusion, but still give people that are used to certain tool steels the same properties and performance they’re used to — if not better.”

“For tooling applications, most people are after a combination of hardness and ductility,” says Jonathan Trenkle, vice president of research, development and operations at Formetrix.

Formetrix believes it has created this alloy with its L-40 product. The company previously formed the additive manufacturing (AM) division of Nanosteel, a developer of advanced steels. Nanosteel’s focus is on sheet steel for automotive and lightweighting of transportation vehicles, a core business that didn’t closely overlap with the tool and die materials being developed by its AM team. In 2018, Formetrix spun out into its own company, giving that AM team more room to grow.

L-40 is Formetrix’s primary product, developed to solve the problems with 3D printed tool steels. “For tooling applications, most people are after a combination of hardness and ductility,” Trenkle. “That’s why H-13 is the workhorse of the conventional wrought steel tool world. We wanted to create a workhorse tool steel for additive manufacturing.”

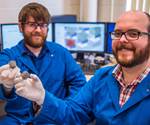

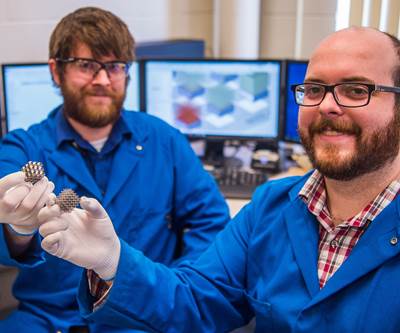

3D printed tooling like this compression die set can support complex geometries and advanced thermal control. However, these applications require a tooling material that is strong and ductile with good printability; Formetrix’s L-40 tool steel alloy was developed with these requirements in mind.

A Printable Alloy for Hardness and Ductility

Despite its widespread use in tools and dies made conventionally, H-13 is not well-suited to the powder bed fusion process because it is prone to cracking during printing. “The only way to really print H-13 in a powder bed fusion system right now is either print it really slowly, at which point it just is not economical, or physically preheat the powder bed up to about 400 or 500 degrees Celsius. Not every printer can do that, and the ones that can take a long time to heat and then cool,” Trenkle says. (Read more about challenges with 3D printing H-13 in this piece.)

Either way, print time or heat/cool time slows the printing process and adds cost when 3D printing this common tooling material; specialty tool steels can be even trickier to print with.

“It’s not the right solution for tool and die.”

One could argue that additive manufacturing already has its tool steel: maraging steel. However, Trenkle says, the printability benefits that maraging steel offers are not matched by its material properties, and it also requires extra steps to process. “You need to do a significant heat treatment after printing with maraging steel to get the hardness in any appreciable level,” Trenkle says. “But what’s more, when you get that hardness, you compromise all ductility. It’s not the right solution for tool and die.”

Material Development Is Chemistry But Also Process

L-40 is Formetrix’s answer to this compromise, a 3D printable tool steel designed to offer a combination of hardness and ductility. Composing alloys for additive manufacturing, though, is not purely a matter of chemistry. Because the microstructure and final properties of the part will be determined by the printing process itself, material development must take into account both chemistry and process parameters.

Starting from the desired characteristics in the final tool, Formetrix uses simulation software to evaluate various chemistries based on how the material can be expected to behave during printing as well as its performance in use.

“We use different models to try to predict behavior,” Trenkle explains. “Will it print without cracking? Will it give us the material properties we want?”

Small batches of promising materials are made by a third-party atomizer, and then tested in prints using the company’s FormUp 350 powder-bed fusion system from AddUp. While early samples and small-scale prints might be used just to evaluate an alloy’s material properties, one that shows promise will be put through more rigorous use.

Equipment for Material and Process Development

“Our core business is developing the process as well as the chemistry,” Trenkle says. The AddUp machine’s open parameters and relatively large printing area measuring 350 by 350 mm with dual lasers offers a variety of processing options to enable this development; an integrated vacuum and quick-change powder handling simplify the material testing process. In addition to AddUp machines, Formetrix provides parameters for other common PBF systems from builders including Concept Laser, EOS, Renishaw and SLM Solutions.

Tool and Die Applications

The benefits of 3D printed tooling are well known for plastic injection molding: ease of incorporating complex design features, the ability to edit or repair molds on the fly by printing new material onto the tool, and the use of conformal channels for thermal control. L-40 brings many of the same benefits to tooling such as hot stamping, die casting and compression dies, with material properties that support these demanding applications. Out of the printer the material offers more than 10% elongation and hardness of 46 to 48 HRC; with case hardening it can reach up to 70 HRC, Trenkle says .

L-40 has proven to be well suited to applications such as compression dies, tools for die casting, and inserts for hot stamping like this one.

In some cases a 3D printed L-40 tool has helped fill the need for a complex mold that proved too difficult to machine. One customer, Perfect Lock Bolt America, had struggled to create a compression die set (the one shown in the image at the top of this story) for its specialized structural bolts using subtractive techniques with D2 and M2 tool steels. Dies 3D printed with L-40 and case hardened were able to deliver the complex profile necessary to form the thread design.

But L-40 has also provided an alternative to tools 3D printed with other materials. In another case study on the company’s website, Formetrix built an L-40 version of a die-cast tool for an automotive part to be compared to a customer’s M300 maraging steel tool. Although the M300 mold had good elongation properties as-printed, a necessary age hardening heat treatment reduced its ductility and the mold failed after 2,000 shots. The same design printed with L-40 and case hardened delivered more than 50,000 shots.

“With the costs of printing coming down, people are starting to realize its benefits for tooling and die, and steel in general.”

Of course, it may not always be economical to 3D print a complete mold. The L-40 alloy has also been used in a hybrid approach, layered on top of a conventionally manufactured tool to provide necessary detail and improve its lifespan. In one example, a Tier One automotive supplier made a die insert for host stamping door beans from sheet steel by printing L-40 onto wrought H13; the insert has produced more than 100,000 parts to date.

While L-40 is the company’s primary commercial product at the moment, Formetrix is also developing other alloys, all steel-based for tool and die challenges. “With the costs of printing coming down, people are starting to realize its benefits for tooling and die, and steel in general,” Trenkle says. “Steel is set to keep us busy for a while.”

Related Content

Additive Manufacturing Versus Cavitation

The design freedom possible with laser powder bed fusion (LPBF) metal 3D printing is making it faster and easier to produce complex anticavitation devices for valves.

Read MoreVideo: How Multimaterial Laser Powder Bed Fusion Works

Penn State University’s CIMP-3D is exploring applications of the Schaeffler Aerosint system for multimaterial 3D printing. During a recent visit, I got an introduction to this system.

Read MorePreassembled Turbojet Engine, 3D Printed in One Build: The Cool Parts Show #75

Turbojet engines typically consist of hundreds or thousands of parts, but this engine — 2023 winner of The Cool Parts Showcase for Best Proof of Concept — was 3D printed as just two pieces, with the monolithic rotor embedded inside the stationary engine shell.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreRead Next

Additive Manufacturing Moves Toward Tailored Materials

A conversation with Carpenter Technology suggests that AM is moving past existing materials toward specialized and eventually fully custom options. The company’s CarTech Puris 5+ titanium powder is one illustration.

Read MoreIn Automotive, Is Additive Manufacturing an Answer for Die Cast Tooling?

The largest high-pressure die cast tool builder in North America is 3D printing die inserts and water jackets for major automakers. It’s a tough sell, but one company is succeeding — and it’s just getting started.

Read MoreNew Opportunities for Quantum Physics: The Cool Parts Show #11

What does 3D printing have to do with quantum physics? We'll look at how the technology is enabling quantum physics research in this episode of The Cool Parts Show.

Read More

.jpg;width=70;height=70;mode=crop)