Wes Byleveld has gotten used to working backward in his sales pitches. The bottom line, he tells Exco Engineering’s automotive customers, is that additively manufactured die cast components can provide a distinct competitive edge. He shows how 3D-printing conformal cooling channels close to the surface of these tools creates a thermally balanced die, and how the benefits cascade into decreased cycle time, lower scrap rates and lower labor costs. And yes, he goes on to say, the mechanical performance of inserts and water jackets printed with maraging steel, which is suitable for sintering via the powder-bed fusion (PBF) process, equals or exceeds the performance of H13 tool steel. Using thermal stress simulations and real-world testing, he presents years’ worth of research that backs up his claims.

It’s a pitch that Byleveld has made with a good deal of success for Exco, where he serves as director of additive manufacturing (AM) for the largest high-pressure die cast tool builder in North America. Exco’s top customers are are the Detroit Three automakers, but the list extends to just about every major automotive brand known to the United States.

Through their success, Byleveld and his team of additive champions at Exco seem to be quietly altering the definition of what “production” means when it comes to 3D-printed components for the auto industry.

The result of Byleveld and Exco Additive’s work is that several powertrain, body and structural components on the road today or in the near future will likely be produced with 3D-printed die cast tools. Considering that roughly 70 million cars are produced each year, this is no small feat. But more impressive — and more important to the way we think about additive manufacturing’s role in the industrial landscape — is how Exco has incorporated metal 3D printing into one of the harshest manufacturing environments imaginable. As Byleveld explains, it started with simple curiosity.

Exco’s facility in Toronto comprises 130,000 square feet of heavy-duty machine tools, including a 4000-ton high pressure die cast machine and three massive furnaces — an inhospitable environment for metal powder-based 3D printing.

Insert Additive Here

Wes Byleveld has been with Exco Engineering for 15 years, beginning in the company’s die cast department doing robotic programming work for die casting process- and workflow-related issues. But for the last four years he’s been fully dedicated to additive manufacturing, an initiative that he says began after learning that one of Exco’s competitors had begun experimenting with the technology. “It was curiosity more than necessity,” as he puts it. But after an initial round of positive benchmarking tests — fueled by the potential to drastically decrease temperatures via 3D-printed conformal cooling channels — Byleveld says he was given broad latitude to bring additive manufacturing into Exco’s production tools.

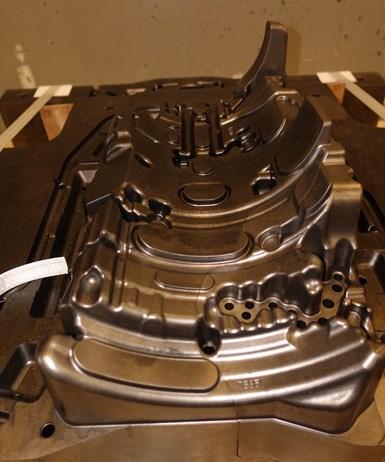

Industrial-scale die casting — the process of forcing molten metal at extremely high pressure into a mold cavity — is an extremely inhospitable environment for metal powder-based 3D printing. Exco’s facility in Toronto comprises 130,000 square feet of heavy-duty machine tools, including a 4000-ton high pressure die cast machine and three massive furnaces. Exco produces several automotive dies for critical parts, including engine blocks, transfer cases, instrument and body panels, wheels, and engine cradles. To be clear, Exco produces the dies and tooling for these parts, not the parts themselves. Some of the dies that Exco ships to customers, such as a V8 engine block die, can weigh hundreds of thousands of pounds.

A finished die ready to be shipped to one of the Big Three automakers.

A typical die produced by Exco consists of several components, some of which require complex machining operations for intricate features such as threading and cooling channels. The die cavity insert is a prime example of this. As the name implies, die inserts — which are machined separately due to their geometric complexity — are inserted into a pocket of the die when finished. While machining inserts as standalone components allows the cutting tool to access external faces of the part, internal cooling channel geometries are still limited to basic linear shapes. Because of this, inefficient cooling of the die during and after the casting process creates thermal imbalance, which causes several problems further down the production chain.

As Byleveld and his team learned, the transition to 3D printing die casting inserts wasn’t as simple as purchasing the right printer. In fact, the act of finding a 3D printer capable of producing automotive die casting parts — and surviving in a die casting environment — was itself a challenge. As a benchmark part, Byleveld selected an engine block water jacket, a part that features a thick base and extremely thin walls. Byleveld then sent water jackets to several 3D printer OEMs with a challenge attached: “If you can build this part for us, we'll buy your machine,” Byleveld said. “EOS was the only company that took it on and said, ‘Yes, we'll give it a try and we're going to succeed no matter what it takes.’”

In 2015, Exco purchased its first 3D printer, an EOS M 400. The next obstacle to overcome was a materials-related issue: H13 tool steel — the standard material used for Exco’s dies — doesn’t play well with the powder bed fusion process.

Test strips can be used to determine the bend rate across a certain distance, the results of which can be input into a modeling method for pre-stressing 3D printed inserts.

The Trouble With H13

“Materials are the name of the game,” Byleveld says. The problem with laser sintering H13 alloys, he says, is that the high degree of carbon in the steel leads to the formation of microcracks throughout the material just like traditional welding. Even with a properly preheated system done just the right way, defects will persist and lead to a highly unreliable part that may get a lot of shots one time and as low as 75 the next. “It’s extremely hard to produce additively,” Byleveld says. “When you look at some of the parts printed with H13, they're cracked and full of porosity. When you're injecting metal at 13,000 PSI in 20 milliseconds, and you have a waterline 1 mm from the surface, if that water line burst during metal injection it blows open the machine. It's a big safety concern for me.”

The material solution that Byleveld and his team landed upon is one that dates back to a previous generation of die casting: maraging steel.

Maraging steels were developed in the 1960s for high strength pressure vessel applications, specifically rocket motors casings, and were for a time used widely throughout the automotive die casting industry. With its low carbon content, maraging steel is extremely weldable and thus ideal for the powder bed fusion process. Combined with the proper heat treatment and aging processes, Byleveld says that the overall mechanical properties of maraging steel meet and exceed traditional tool steels for die casting while maintaining a high level of dimensional stability and low distortion.

Exco’s heat-treatment process, shown here, has allowed the company to use maraging steel in place of H13 for its 3D printed inserts.

Through trial and error and several commissioned studies with a local university, Exco has created a proprietary heat-treating process for 3D printed maraging steel that Byleveld says results in a hardness similar to H13, but with much lower porosity and a higher resistance to cracking. “The material lasts,” he says. “We’ve printed die inserts from maraging steel that have lasted more than 150,000 cycles.”

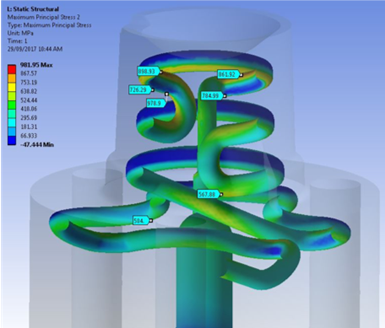

This stat is all the more impressive when you take a close look inside the looping geometries of a 3D-printed die insert.

In these 3D-printed test parts, a slight teardrop shape can be seen in the tube on the left. Stress can concentrate within this shape, leading to failure of the part. Exco has experimented with other channel shapes to offset this problem.

The Eastern Block

The rule of thumb for cooling channels within a typical insert is that they must reside no less than 0.75 inches from the die casting surface. Anything closer to that risks failure. But thermal and mechanical simulation testing has allowed Byleveld and his team to push the limits with 3D printed conformal cooling channels, placing them within a fraction of the conventional minimum of 0.75 inches.

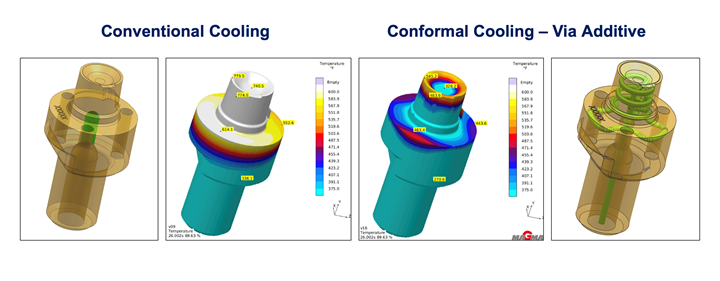

A heat map shows the drastic temperature differences achieved with conventional (linear) cooling channels versus conformal, 3D-printed channels.

Exco is also closing in on the ability to pre-stress CAD models in a way that offsets bending and warping that takes place during the printing process. Byleveld showed me printed test strips that he measured on CMM in order to determine the bend rate across a certain distance — the results of which can be input into a modeling method for prestressing inserts. The smaller the insert, the easier this is to accomplish, Byleveld says. This work was part of the motivation for Exco to invest in its second metal 3D printer, an EOS M 400-4, in which four, 400-watt fiber lasers operate in separate quadrants with 100 mm of overlap area in the center. Because a single, large part can now be made with multiple lasers at the same time, the part stays warmer for longer. Because the delta change in temperature is what leads to warpage, keeping the entire part at a steady temperature limits the overall distortion.

This simulation model shows low stress levels throughout the shape of the cooling channels.

Conformal cooling channels have long been touted as a key benefit for utilizing 3D printing in the mold-and-die industry. And Exco’s investment in bringing additive manufacturing to automotive die casting bears this out. Thermal balance within a large automotive die, which contains a dynamic range of thick and thin sections shot through with liquid aluminum, is extremely difficult to control. The ability to do so impacts not only performance, but also cycle time, scrap rates and labor costs — all critical factors in an increasingly competitive global market, especially from Eastern Europe.

While powder costs for additive manufacturing — as well as the time and capital expenses on refining the printing processes — elevate the costs for 3D-printed parts like die inserts and water jackets by two-to-five times, Exco says that its parts not only out-perform traditionally manufactured dies, but save substantial time during the solidification process. This, in turn, results in substantial cost savings during the die lifecycle.

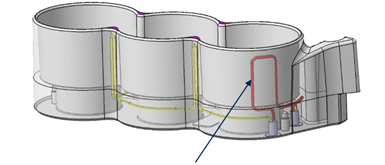

Another example of linear versus conformal cooling channels.

Contrast that with intricate setups on a five-axis machine to drill difficult angles, which wastes not only valuable time but also substantial amounts of material. Not to mention that complex machining also requires skilled labor to perform the task. “You can imagine on a 200,000-pound die, as delivered, we're probably removing 40 to 50 percent of material conventionally,” Byleveld says. “You buy a hundred-pound block of H-13 at $5 a pound and whittle it down to 30 or 40 pounds and get 10 cents on the dollar for your waste. Same with a large die insert; you remove 40 percent. With additive, you're only producing what you need plus a little bit of machine stock. Yes, the material is much more expensive, but it actually starts coming closer and closer to conventional manufacturing.”

Because this might not be intuitive to his customers’ purchasing departments, Byleveld says that the most important role can be that of a sales engineer. What is the hourly cost on a machine? What is the ROI for a part that lasts several times as long as a traditional part? The savings, he says, can be thousands of dollars compared to a traditionally produced insert.

10,000 Cycles

Ultimately for Exco, delivering dies that out-perform those that are traditionally manufactured allow customers like GM and Chrysler to produce parts faster and remain profitable. One critical component that Byleveld believes can be drastically improved via additive manufacturing is the water jacket — the benchmark part that won EOS the company’s business.

Wes Byleveld, director of additive manufacturing for Exco Enginnering, the largest high-pressure die cast tool builder in North America.

Water jackets inserts essentially create the coolant channel within an engine block. They are difficult to machine, let alone print, due to the variance in thickness of the curved walls from top to bottom. Because temperatures can vary across the face of a water jacket die by as much as 220°F, solder buildup often occurs during the metal injection phase of the casting. Machine-related downtime associated with polishing solder is itself costly. Eventually, fatigue in these areas will crack through the water jacket and result in leaks between the coolant and oil passages on the engine block itself. The typical cost to an auto manufacturer can be upwards of $10,000 per insert, and these inserts often last fewer than 15,000 cycles before having to be discarded.

Byleveld says that one of his Big Three automaker customers is testing 3D printed water jackets that contain a water line near the surface to substantially decrease the temperature variance and limit solder formation. While the central geometry of the 3D-printed water jacket is no different than a conventionally produced part, Byleveld is betting that, even at five times the cost, the expense of an additively produced jacket is more than justified when you calculate increased performance, longevity, and machine-related downtime associated with polishing solder.

Conformal cooling channel on a 3D-printed water jacket.

Full adoption of 3D-printed water jackets by automakers has the potential to be a game changer for Exco in many ways. The company produces roughly 500 of these parts per year conventionally. Byleveld says that even producing 200 a year additively — assuming that the performance enhancements doubled the shot life result — it could justify Exco purchasing another two or three additive machines.

Before that happens, the benefits will need to be made clear, Byleveld says. The durability of 3D-printed parts like the water jacket will have to bear out during testing. And a mindset change may need to occur among customers who may consider bottom-line costs before calculating savings for material, labor and performance. “You know, it's a tough sell sometimes, because the cost of one of our additively produced inserts is two- to five-times the cost of a conventional one,” he says. “But when the conventional is a thousand dollars and you're only charging you know three or four thousand for it but you're getting all the benefits, that’s where the real savings are for people.” Until that’s widely understood, he says, he’ll keep doing what he’s been doing: Starting his sales presentations at the end, and working his way back.

Related Content

What Holds AM Back in Automotive Production? GM Additive Lead Describes Advances Needed

“If AM were cheaper, we would be doing more of it,” says GM’s Paul Wolcott. Various important factors relate to cost. However, the driving factor affecting cost is speed.

Read MoreDo Distributors Dream of Digital Inventory? Würth Additive Group Does

It’s more than a dream for Würth Additive Group and its parent company, in fact. Along with supplying additive equipment, the group is now developing solutions for sourcing 3D printed parts in a reliable, elastic digital inventory model.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreBMW Expands Use of Additive Manufacturing to Foster Production Innovations

The BMW Group is manufacturing many work aids and tools for its own production system using various 3D printing processes, with items such as tailor-made orthoses for employees, teaching and production aids, and large, weight-optimized robot grippers, which are used for such things as carbon fiber-reinforced polymer roofs and entire floor assemblies.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More