Mold Tooling

Stratasys, ECCO Partner to Innovate Footwear Manufacturing Using 3D Printing Technology

Stratasys Origin One 3D printers and custom materials from Henkel Loctite are said to lower costs and shorten mold fabrication time.

Read MoreMVP Updates Large-Scale Thermoset Composite AM System

The RAM 48 has a print area of 4 ft. × 8 ft. with modular, expandable 4 ft. × 4 ft. sections to enable custom build dimensions.

Read MoreAirtech’s Dahltram Resins Approved for Use on All Thermwood LSAM 3D Printers

The company says its Dahltram range of resins are suitable for multiple print platforms, providing production flexibility with end-use material validation.

Read MoreWestminster Tool Awarded $100,000 Grant for Additive Technology

Westminster Tool joins six manufacturing companies in Connecticut as recipients of the latest Additive Manufacturing Adoption Program (AMAP) grant.

Read MoreOver 1 Million End Parts Produced With Mold Made on Mantle Metal 3D Printers

Over 1 million end-use plastic parts produced using mold tooling made via the TrueShape system for making precise steel tooling rapidly using 3D printing.

Read MoreResearch Partners Building World’s Largest Sand Binder Jetting Printer

3D printing provides flexibility to produce large turbine components near offshore wind projects, lowering transportation costs and offering environmental benefits.

Read More‘Tera 250’ Becomes ‘Fabrica 2.0 Machine” Following Acquisition by Nano Dimension

Nano Dimension changes name of Nanofabrica Ltd. to ‘Nano Dimension’s Fabrica Group.’

Read MoreExOne Launches X1 Tooling Industrial-Grade 3D Printed Tooling Solutions

X1 Tooling offers manufacturers fast, affordable and local tooling options for the final production of metal, plastic and composite designs.

Read MoreEssentium Acquiring Collider's DLP AM Technology

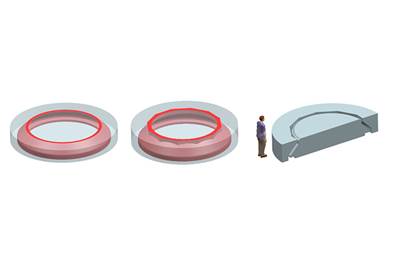

Company plans to advance Collider’s Programmable Tooling, which combines the speed of Digital Light Processing 3D printing and the material strength of injection molding.

Read MoreErofio Group 3D Prints First Part on GE Additive Concept Laser M Line

Mold core successfully additively manufactured on first attempt, using hot work tool steel, in a six-day test build.

Read More