3D-Printed Device Proves Rugged Enough for Dust-Free Tile Removal

Arizona Home Floors considered buying a mold to produce a plastic version of its DustRam product. But when a prototype proved durable enough to withstand working conditions, the production strategy shifted to 3D printing.

The sales force at Arizona Home Floors frequently encounters contractors and homeowners who are skeptical that the company’s technology can remove flooring without leaving dust behind. One of the tools that makes this claim possible is the DustRam, a chipping hammer accessory developed by company founder Jack King that enables vacuuming while breaking apart tile flooring. Seeing the device in action (and the results it leaves behind) is often what it takes to prove the skeptics wrong.

Yet King himself was skeptical when one of the company’s engineers suggested 3D printing a DustRam prototype, and then actually using that prototype for testing in the field. “I fully expected that it was going to shatter and break all to pieces,” he says, citing the demanding working conditions of floor demolition and the fact that the original DustRam is made of metal. But to his surprise, that 3D-printed prototype lasted far more than a couple of hours. The nylon device was used in tile removal operations for a full six months before the opening in the nose wore away too much and it had to be discarded. Seeing its success firsthand caused King to view 3D printing differently, and changed the way his company’s products are designed and produced.

Designing for Dust-Free Demolition

King began developing equipment for dust-free tile removal about nine years ago, when the market for new housing construction took a hit and Arizona Home Floors refocused its efforts on remodeling. He found that the products available on the market were insufficient for dust-free tile removal, adding time and complexity as well as potential health hazards to renovations. In search of a cleaner and faster solution, he began developing his own products, starting with high-pressure lines and manifolds for vacuums. Today Arizona Home Floors sells its products to other contractors, but still uses them in its own renovation services business.

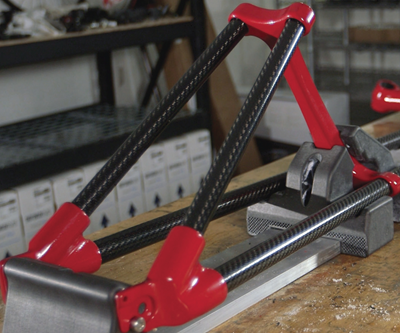

The DustRam is one of these products. The device fits around the chisel of a Bosch chipping hammer and connects to a heavy-duty vacuum system. The vacuum runs simultaneously with the hammer, immediately pulling in any dust for a cleaner work environment and faster flooring removal. The DustRam and vacuum are part of an equipment package that also includes grinding wheels and shrouds plus debris removal and handling equipment. In addition to tile and stone, the system can be used in the removal of wood flooring, ceramic wall tile and other home construction materials.

The original DustRam is made from machined aluminum and S7 tool steel. The manufacturing process entails CNC machining, TIG welding, heat treat and wire EDM; because all of these steps must be outsourced, it takes four or five months to produce a set of 10 or 15 DustRams. The finished accessory weighs 12 pounds and retails for more than $8,000. It is highly effective at capturing dust and rugged enough to help pry up tile during demolition, but is also heavy and difficult to work with for long periods of time.

To reduce weight, the company decided to develop a plastic version of the DustRam. Given the expense of designing and manufacturing molds, Michael Hadley, lead engineer for DustRam, suggested 3D printing a prototype first. The company turned to Eric Miller, co-owner of Phoenix Analysis & Design Technologies (PADT), for help with this task, having previously sourced some 3D-printed Ultem vacuum parts from PADT.

The initial DustRam prototype was 3D printed as a single piece of nylon in 50 hours, and weighed less than 3 pounds. The cost, time and labor savings were significant, but King predicted it wouldn’t last even a day in the field. After that prototype survived not just a full day, but months of heavy use, King saw an opportunity to expand the DustRam product line without buying into a mold at all.

Making Adjustments

Impressed by the durability of the 3D-printed nylon DustRam, King purchased a Stratasys Fortus 450mc from PADT, and began to develop a version of the product to be 3D printed in the same flexible nylon as the prototype. The product’s original design proved to be well-suited to 3D printing already, with the exception of one feature: the nose.

In the metal version of the DustRam, the nose is machined from S7 tool steel and is used to help pry up old flooring during demolition. The flexible nature of the nylon prevented the 3D-printed version from being used this way, but the nose still took more wear and tear than the rest of the device.

To account for this wear, the way that the nose attached needed to change. In the metal version, the tool steel nose is pinned to the DustRam’s aluminum body and is not intended to be removed. In the printed version, it is attached with two screws; the company now sells replacement 3D-printed noses for around $300 that users can easily install themselves when one wears out. (The typical lifespan for a nose is six months to one year, King says.)

This new design has a manufacturing time of about 55 hours, including the 3D printing, a soak in sodium hydroxide to remove supports, installation of brass inserts and assembly. This is far faster than the months-long turnaround for the metal DustRam, and avoids the added machining, welding and heat treat steps that version requires.

But the 3D-printed DustRam isn’t a replacement for the metal version; instead it is a lower-cost option, retailing for about one-third the price of the original. Contractors who aren’t ready to purchase the metal Dustram can make a smaller investment in the 3D-printed version. Its lighter weight also makes the 3D-printed version easier to use on vertical surfaces or for long periods of time, reducing operator fatigue.

Ongoing Production, Continuous Improvement

The company currently prints small volumes of the DustRam in-house on the Fortus 450mc. To buy a mold to make this device would have cost about $100,000, says King, and the molded product would have required traditional machining before assembly.

When it isn’t printing DustRam parts, the Fortus 450mc is also used for short production runs of other products, including at least 10 different parts that go into specialized vacuum systems. Others are an accessory that keeps a Bosch hammer from dragging through sand and grit, and a nylon-printed component designed for wood flooring removal and stacked stone demolition.

The 3D printer prints in both nylon and ASA, and rotates between the two materials every few weeks. The company is looking into buying a second Fortus 450mc to keep up with production. Adding a second 3D printer will provide flexibility to print a greater variety of parts at once, or to knock out larger orders more quickly. King places such confidence in the quality of the 3D-printed product and the company’s ability to fulfill production needs that he has no intention of purchasing an injection mold any time soon.

From PADT’s perspective, “This is the classic example of someone who comes in looking for a prototype, and discovers what you can really do with 3D printing,” Miller says. “We have eliminated the whole need for a manufacturing supply chain for these parts.”

“I’m my own manufacturer now,” King agrees. With the 3D printer and assistance from PADT, he has been able to bring manufacturing in-house without being an expert in manufacturing, and without being impeded by the constraints of traditional manufacturing.

But it’s not just about being able to manufacture products. It’s about being able to manufacture better products.

As an inventor, “I keep finding new and better ways to do something,” King says. Thanks to 3D printing, he says, “Within two hours my engineer can substantially change a design. I can grow it in the next couple of days, try it out and see if it worked. We can make little micro changes along the way.”

And King and his team know just what changes to make. As a company that both sells and uses the products it designs, Arizona Home Floors is now positioned to continuously improve solutions to the problems it faces every day.

Related Content

Why AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreRead Next

3D-Printed Prototypes Become the Parts with Carbon Fiber Filled Filament

Utah Trikes, a retailer and manufacturer of trikes and quads, has grown its custom business using FDM Nylon 12CF to produce end-use composite parts that formerly would have required moldmaking.

Read MoreOrion Gets a Lift from Electro-Static Dissipative (ESD) Material

NASA’s Orion spacecraft will include parts 3D-printed from electro-static dissipative Antero 800NA from Stratasys. Developing this material was an exercise in working within constraints.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More

.jpg;width=70;height=70;mode=crop)