Biomimicry: Nature’s Way of Cooling Tools with DMLS

Research leveraged biomimicry, a design method based on structures and systems found in nature, to develop a better mold.

Conformal cooling using direct metal laser sintering (DMLS) enables users to seamlessly build cooling channels where they are most needed while creating a part layer by layer. This technique has proven to increase product quality and reduce manufacturing times, but what happens once you’ve maxed out your potential for conformal cooling? This is exactly what happened to Harbec Inc., a New York-based manufacturer of precision plastic and metal products. According to Keith Schneider, Harbec general manager, the company then decided to look to nature to find new ways to further enhance mold cooling in a process called biomimicry.

Biomimicry is the design and production of materials, structures and systems that are modeled on biological entities and processes. It involves looking at nature and trying to find the nuances and great things that nature has created and then implement them through manufacturing and engineering. It’s learning from the natural efficiencies of nature. For example, Velcro was inspired by burrs.

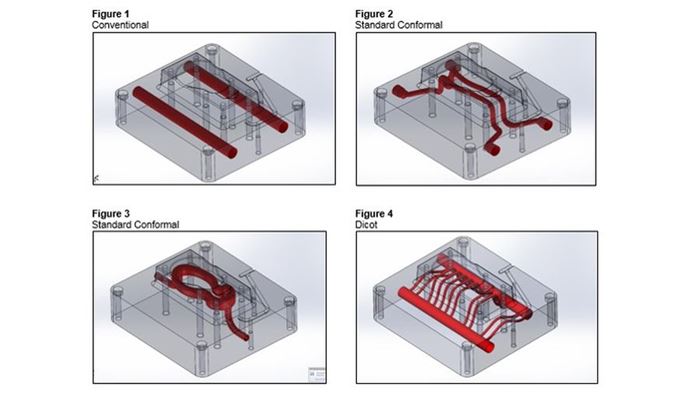

Harbec’s inspiration to improve mold cooling came from leaves and the vein structures in the mammalian vascular system that mimic cooling lines. The company partnered with the New York State Energy Research and Development Authority to research biomimicry in DMLS injection molds by comparing conventional and conformal cooling lines, illustrated in the figure above. This research was completed on an EOS M290.

To determine the proper leaf structure for the required balance to obtain optimal cooling, Harbec used FEA on numerous design iterations. They selected the dicot leaf structure (pictured above), which offers a number of possible variations through its trunk and capillary lines. The trunk lines were used to control volume and the capillary lines to control flow. Overall, this was relatively easy to mimic from both an engineering and manufacturing perspective. Balance and flow were the biggest challenges, according to Schneider.

Testing of the four molds showed that the dicot DMLS conformal-cooled tool improved cycle time and reduced energy consumption by more than 20 percent.

Related Content

-

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

-

Preassembled Turbojet Engine, 3D Printed in One Build: The Cool Parts Show #75

Turbojet engines typically consist of hundreds or thousands of parts, but this engine — 2023 winner of The Cool Parts Showcase for Best Proof of Concept — was 3D printed as just two pieces, with the monolithic rotor embedded inside the stationary engine shell.

-

Seurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.