Design Enhancements for Conformal-Cooled Insert Leverage 3D Printing Capabilities

A collaborative mold project reveals that the value of 3D printing isn’t in the process, it’s in the products.

In a project launched with the intent to prove that conformal cooling is not only feasible, but also accessible, Diamond Tool and Engineering recently produced an injection mold that was designed to push the limits of traditional moldmaking. A direct metal laser-melted conformal-cooled insert was essential to the project’s success.

Diamond is a precision plastic injection mold builder headquartered in Bertha, Minnesota, that specializes in tight-tolerance, multi-cavity tooling for the medical industry. To build the conformal-cooled injection mold, the company turned to 3DPrintedParts.com. The AM provider located in Grand Rapids, Michigan, approached the project with an eye toward leveraging the capabilities of direct metal laser melting for this specific mold.

“A lot of people approach 3D printing as a speedy process that will replace conventional manufacturing, which isn’t necessarily true. The value isn’t in the process, it is in the products,” says Mike McLean, general manager of 3DPrintedParts.com.

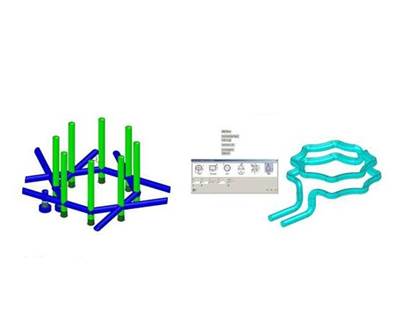

With direct metal printing, 3DPrintedParts.com focuses on printing only the features that add functional value for a part. “A conventionally designed insert would be machined out of billet and it would be wasteful to cut away material that doesn’t contribute to the final part. With 3D printing, it’s the opposite. It is wasteful to use material that doesn’t contribute to the final part,” says McLean. He calls this a focus on intelligent geometry, which he believes has a two-fold impact: less time under the laser, which reduces the cost of the insert, and less finished mass within the insert, which enhances the thermal management capacity of the conformal cooling channels.

After a brief 30-minute consultation with Diamond, 3DPrintedParts.com was able to deliver the part within days of receiving CAD data, with a negligible extension of a normal tooling lead time. The mold was printed on a 3D Systems ProX300 direct metal printer, chosen for the application “because of its unique roller mechanism that reaches the highest density parts of any direct metal printer,” McLean says. This density ultimately impacts the wearability of the finished insert, which is a critical aspect of a printed part.

The consultation at the beginning of the project led to design enhancements that leveraged the capabilities of the 3D printing process. In addition to the conformal cooling, the design team at 3DPrintedParts.com identified regions of the mold that could be replaced with a lattice structure instead of being printed solid throughout.

McLean says he learned a lot about 3D printing and conformal cooling as a result of working on this project. For example, you can apply conformal cooling very cost effectively to products if you are willing to focus on printing intelligent geometry. This means, to leverage 3D printing economically, you must be willing to change conventional design thinking (although some rules still apply). The starting point isn’t a solid block of material, so you’re not limited to producing heavy and dense objects, which ultimately drive costs.

Also 3D printing is accessible from a cost perspective if the design constraints of the direct metal printing process are anticipated in the final part or insert design. For example:

- Less mass is more savings. To solidify parts, the machine uses a laser to weld a fine powder. More mass equals more time under the laser.

- Unsupported undercuts. Most metal printers on the market require any undercuts greater than 35 degrees from horizontal to be supported by engineered-support trusses. The ProX300 used by 3DPrintedParts.com can print unsupported overhangs down to 25 degrees from horizontal, which allows for more aggressive geometries to be printed without additional machining.

- Height-to-thickness ratio. Generally, height-to-wall thickness ratios should be no more than 15:1.

- Powder removal. Any cooling channels will be filled with unmelted powder, so it is important to provide an escape route for that powder.

- Cooling channel shape. A circular helix might look nice or be simple to model, but isn’t necessarily the most effective at getting water where it’s needed. The profile of the cooling channel can change shape as needed.

The printed cavity along with a collapsing core designed by Diamond Tool resulted in a cycle time reduction from 35-40 seconds conventionally to 6.7 seconds with the enhanced design.

Related Content

8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreIn Casting and Molding, AM Simplifies Conventional Manufacturing

In new ways, additive processes are streamlining and enabling metal casting and plastic injection molding.

Read MoreRead Next

Design Guidelines for Conformal Cooling Water Lines

Additive manufacturing enables complex geometries and nonround cross-sections for conformal cooling lines, but some design lessons from conventionally drilled lines are still relevant.

Read MoreVideo: Moldmaker Succeeding with Conformal Cooling

B&J Specialty now complements its machining capabilities with metal 3D printing for making mold inserts with cooling channels that follow the contours of the mold. The shop is even revisiting challenging molds from the past.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More