Metal

“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

Read MoreAdditive Wins on Cost, Plus Process Monitoring and More from RAPID + TCT 2023: AM Radio #38

Additive manufacturing is finding success as a cost-effective manufacturing method. New options for process monitoring are now available. DED is getting more precise. 3D printed chairs! What we learned and observed at RAPID + TCT 2023.

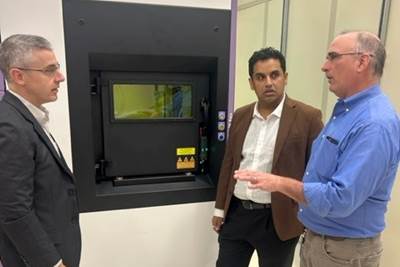

ListenSix Years After Launch, OSU Has a Leading Facility for Metal AM

At the Ohio State University metal additive manufacturing lab, undergraduate students serve as employees on projects aiming to help companies advance with AM. Here is a look inside the facility now running a dozen metal additive systems.

Read MoreDyndrite Collaborates With AMFG for Cross-Platform 3D Metal Automated Production

AMFG powered by Dyndrite is an integrated solution that is said to unlock the full potential of metal 3D printing by bringing order-to-part automation, eliminating bottlenecks and streamlining the entire production process for increased efficiency and cost savings.

Read MoreHP Expands Automation Solutions for Advancing 3D Printing Path to Production

HP’s Jet Fusion automation solutions are designed to simplify workflows and reduce costs for high-volume 3D production. The company has also expanded its materials, HP Digital Production Suite and HP Digital Production Services for polymer and metal customers.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

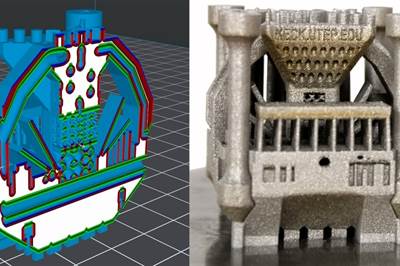

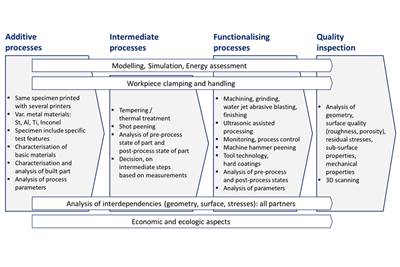

Read MoreResearchers Examine Additive-Subtractive Manufacturing Process Chain

Researchers on the Advanced Processing of Additively Manufactured Parts project examined the additive-subtractive manufacturing process chain to optimize workpiece properties (such as geometry, surface and subsurface characteristics) throughout the entire process chain.

Read MoreUniFuse IN625 Nickel Alloy for LPBF for Higher Throughput, Superior Mechanical Properties

Uniformity Labs says its IN625 nickel alloy powder provides more repeatable and reproducible mechanical properties across the build bed, printed at far higher throughput.

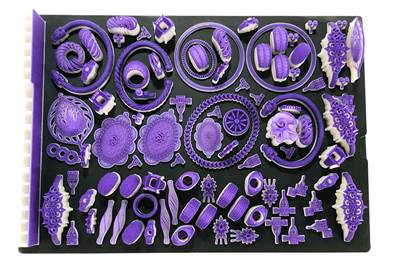

Read More3D Systems’ ProJet MJP 2500W Plus Printer for Improved Jewelry Production

The printer is designed to enable the quick and cost-effective creation, iteration and production of all jewelry styles, including the most complex geometries.

Read MoreDEDSmart Tool Harnesses Data in Real-Time for Build Quality Verification

FormAlloy Technologies’ DEDSmart technology for autonomous DED builds and build data logging utilizes enhanced in-situ monitoring and control, and the power of data, to complete builds autonomously while data logs are automatically exported enabling Digital Build Certification.

Read More